Waterborne polyurethane emulsion, preparation method for waterborne polyurethane emulsion, application of waterborne polyurethane emulsion to wallpaper basement membrane and wallpaper basement membrane

A water-based polyurethane and wallpaper base film technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of undisclosed water-based polyurethane emulsion, water-based polyurethane emulsion does not have waterproof and alkali resistance, etc., to facilitate large-scale production and application , Improve waterproof and alkali resistance performance, and improve the effect of water contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

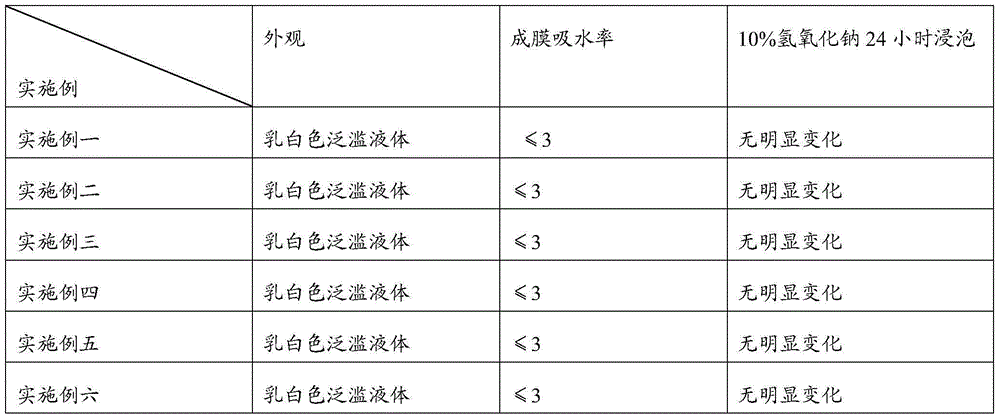

Examples

preparation example Construction

[0040] The beneficial effect of the preparation method of aqueous polyurethane emulsion of the present invention is:

[0041] (1) The preparation method is simple and easy to operate, which is beneficial to large-scale production and application; the prepared aqueous polyurethane emulsion has good waterproof and alkali-proof performance;

[0042](2) Control the mixed reaction of polyester polyol and diisocyanate at 80-90°C, and control the temperature at 70-80°C after adding a hydrophilic chain extender, which can control the temperature within the range of reaction hot spots to prevent excessive reaction Vigorous, to ensure the smooth progress of the reaction, and at the same time, it can improve the reaction efficiency to a certain extent; when adding the salt-forming agent, reduce the temperature to 35-45 ° C, because the previous reaction temperature was high, if it is neutralized under this condition, it will cause heat generation. The temperature of the reaction system i...

Embodiment 1

[0053] Weigh 100 parts of polyester polyol, 45 parts of diisocyanate, 10 parts of hydrophilic chain extender, 7 parts of salt forming agent, 270 parts of water and 0.5 part of end-capping agent containing fluorocarbon group. The polyester polyol is polyadipate-based polyester diol. The diisocyanate is one or more of isophorone diisocyanate, toluene diisocyanate, diphenylmethane diisocyanate and hexamethylene diisocyanate. The hydrophilic chain extender is 2,2-dimethylol propionic acid. The salt-forming agent is triethylamine, and the end-capping agent is trifluoroethanol.

[0054] Mix polyester polyol with diisocyanate, stir at 80°C for 2 hours, then add hydrophilic chain extender, stir at 70°C for 3 hours, lower the temperature to 35°C, then add salt-forming agent, stir well To obtain a prepolymer, add the prepolymer into water stirred at a speed of 800 r / min, stir until the solution is fully emulsified, then add an end-capping agent, and obtain the aqueous polyurethane emu...

Embodiment 2

[0057] Weigh 120 parts of polyester polyol, 55 parts of diisocyanate, 12 parts of hydrophilic chain extender, 9 parts of salt forming agent, 300 parts of water and 1 part of capping agent containing fluorocarbon group. The polyester polyol is polyadipate-based polyester diol. The diisocyanate is one or more of isophorone diisocyanate, toluene diisocyanate, diphenylmethane diisocyanate and hexamethylene diisocyanate. The hydrophilic chain extender is 2,2-dimethylol propionic acid. The salt-forming agent is triethylamine, and the end-capping agent is trifluoroethanol.

[0058] Mix polyester polyol and diisocyanate, stir at 90°C for 3 hours, then add hydrophilic chain extender, stir at 80°C for 4 hours, lower the temperature to 45°C, then add salt-forming agent, stir well To obtain a prepolymer, add the prepolymer to water stirred at a speed of 3000r / min, stir until the solution is fully emulsified, then add an end-capping agent, and obtain the aqueous polyurethane emulsion aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com