Vacuum emulsification device for cosmetic production

A technology for vacuum emulsification and cosmetics, applied in mixers with rotary stirring devices, chemical instruments and methods, dissolution and other directions, can solve the problems affecting the quality of cosmetics, uneven mixing of devices, insufficient mixing of raw materials, etc., to increase protection. performance, protection of the stirring block, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

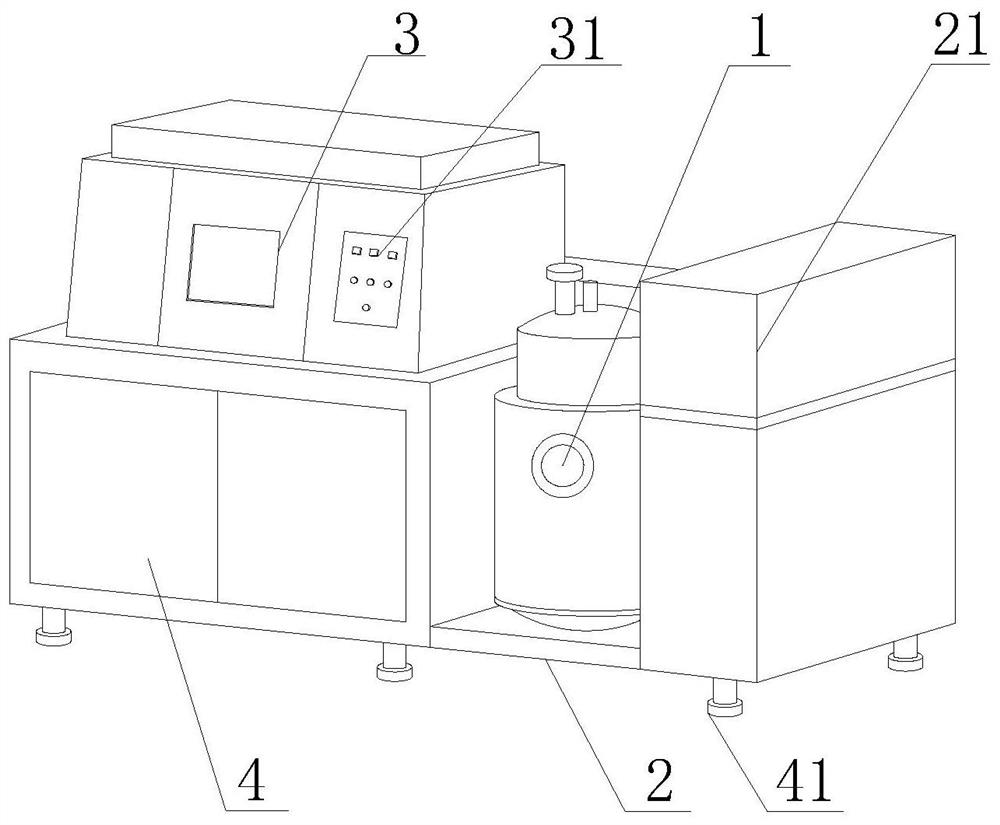

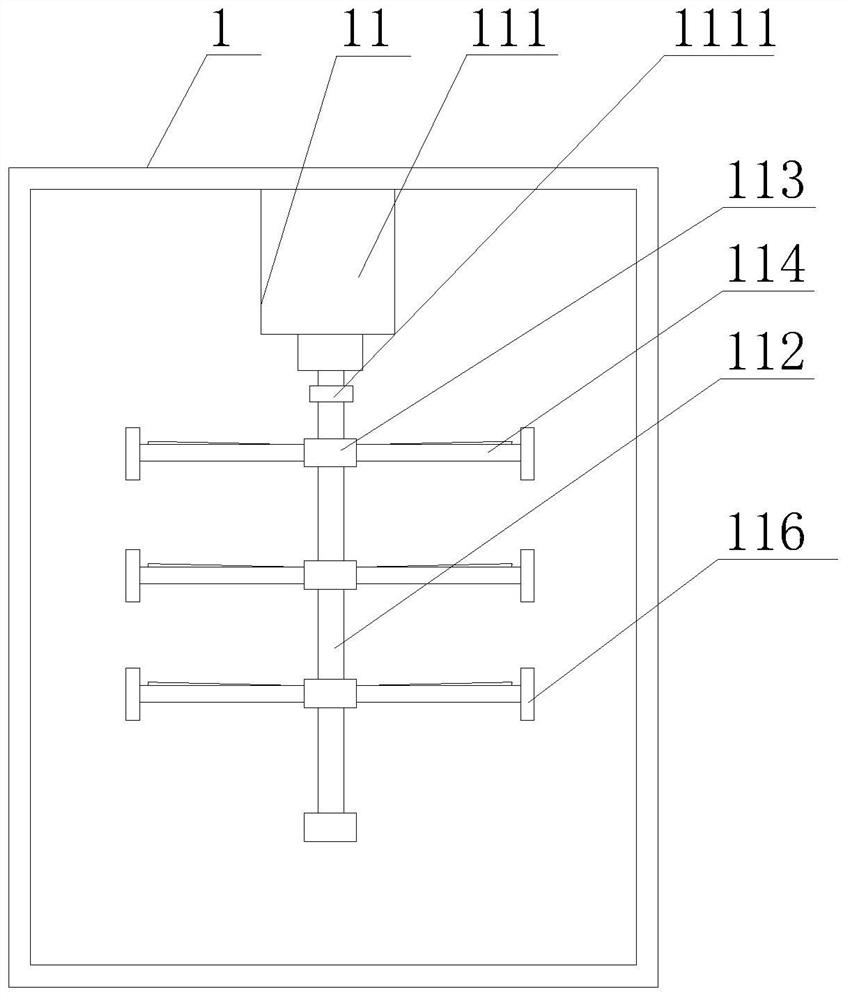

[0041] like Figure 1-7 As shown, the present invention provides a vacuum emulsification device for the production of cosmetics, including a vacuum emulsification device main body 1, a placement frame 2, a console 3 and a base 4, and the bottom of the vacuum emulsification device main body 1 is fixedly equipped with a placement frame 2, One side of the placement frame 2 is fixedly equipped with a storage box 21, the other side of the placement frame 2 is fixedly installed with a base 4, the bottom of the base 4 is fixedly equipped with a support column 41, and the top of the base 4 is fixedly installed with a console 3, the console A control button 31 is fixedly installed on the surface of the vacuum emulsification device, a stirring mechanism 11 is fixedly installed inside the main body 1 of the vacuum emulsification device, and a cleaning mechanism 12 is installed on the side of the stirring mechanism 11. The stirring mechanism 11 includes a power motor 111, and the bottom of...

Embodiment 2

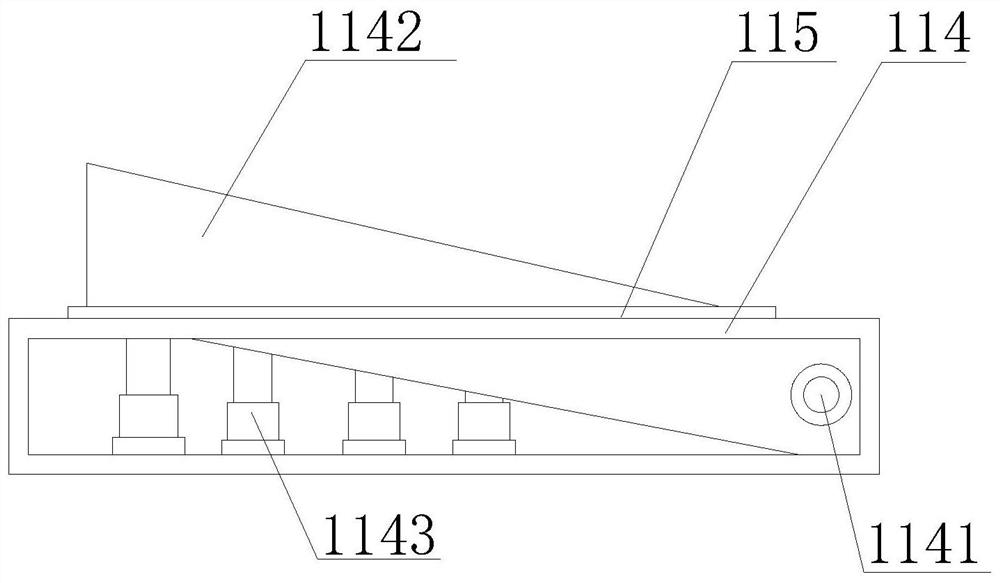

[0044] like Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the inside of the protective layer 115 is fixedly installed with a pressing block 1151, and the bottom of the pressing block 1151 is fixedly installed with a buffer column 1152, and the buffer column 1152 A baffle is fixedly installed at the bottom, an extruding bullet 1153 is fixedly installed on the bottom of the baffle, and an air pressure cushion 1154 is fixedly installed on the bottom of the extruding bullet 1153 .

[0045] In this embodiment, through the mutual cooperation of the pressing block 1151 and the buffer column 1152, the buffer column 1152 is stretched and buffered, and then the elastic force of the extruded spring column 1153 is used to slow down the external force, and then the softness of the air pressure cushion 1154 is used. performance, so as to further buffer the force and achieve the function of protecting the stirring block 1...

Embodiment 3

[0047] like Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the cleaning mechanism 12 includes a connecting column 121, and one side of the connecting column 121 is fixedly sleeved with a socket block 122, and the socket block 122 A scraper 123 is fixedly installed on the side, and the side of the connecting column 121 away from the scraper 123 is movably socketed inside the fixed block 116. The inner wall of the fixed block 116 is provided with an extruding block 1161, and the other side of the extruding block 1161 is fixedly installed. A telescopic rod 1162 is connected, a buffer pad 1163 is fixedly installed on the side of the extrusion block 1161, a friction block 1164 is fixedly installed on the side of the buffer pad 1163, a scraper column 1231 is fixedly installed on one side of the scraper block 123, and the side of the scraper column 1231 is fixed. A lower pressing block 1232 is installed, a scraper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com