Gas-liquid entrainment mixing apparatus and method

A mixing device and gas-liquid technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of insufficient gas-liquid mixing, lack of gas and liquid fluidity, and reduced comprehensive purification efficiency, etc. Achieve the effect of ensuring the excitation frequency, increasing the gas-liquid contact area, and improving the purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

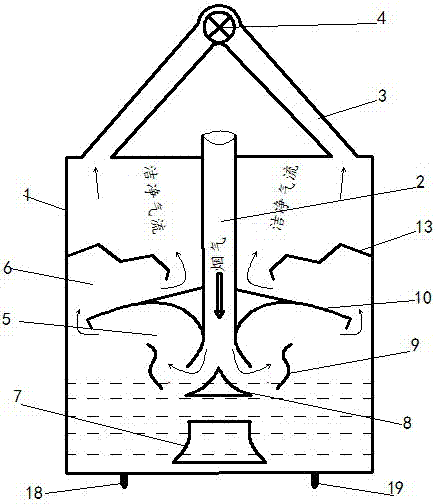

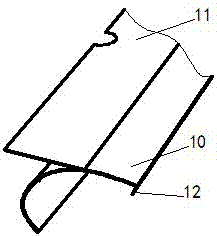

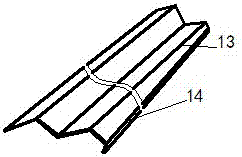

[0046] Such as figure 2 As shown, the ear-shaped plate 10 is made of a 3-5mm thick plate, and an entrainment space is formed at the end with a larger curvature, so that the gas and liquid can be fully entrained, so that the harmful components in the gas can be captured by the purified liquid as much as possible. Collective capture, enhance purification efficiency; and forcefully change the flow direction of the gas-liquid mixture through the right-angle folding plate 12 at the end, further change the distribution state of the gas-liquid mixture in the purification chamber, strengthen the gas-liquid mixing state, and reduce the possible space for harmful components to escape .

[0047] Such as Figure 7 , 8 As shown, the aperture of the liquid phase steady flow device 7 is about 2-3 cm, and it is placed in the middle of the gas-liquid entrainment mixing device close to the bottom surface, and its function is to connect two working chambers 1, at the left and right sides of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com