Semiconductor laser light source module based on planar waveguide combiner and manufacturing method

A planar waveguide and laser light source technology, applied in the field of wave combiners, can solve the problems of large size, high environmental stability requirements, and increased difficulty in coupling and alignment of light sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

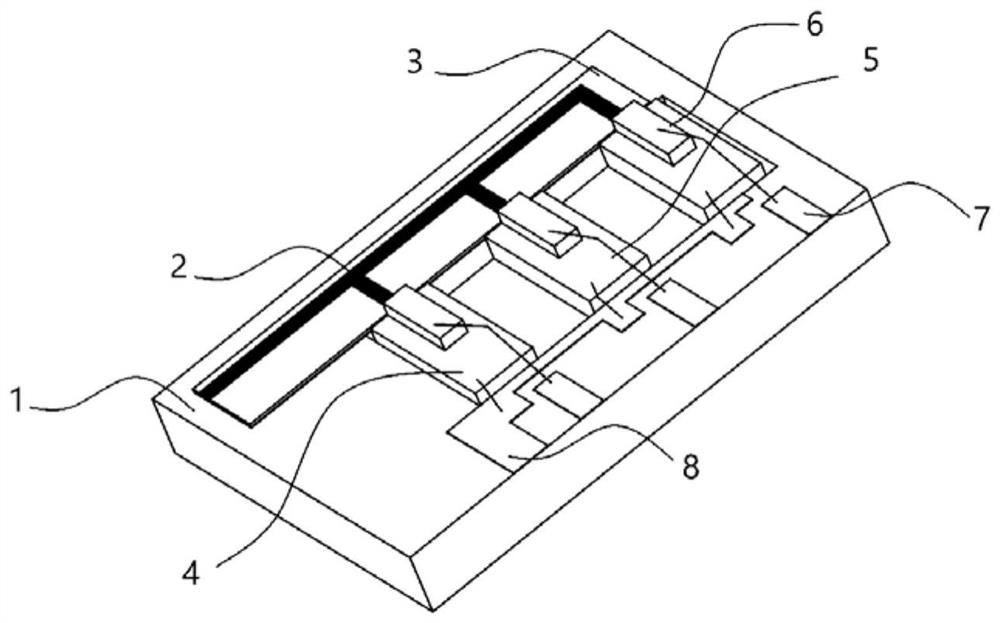

[0053] The first manufacturing method of a semiconductor laser light source module based on a planar waveguide type combiner, comprising the following steps:

[0054] S1, the preparation of the multi-layer composite substrate of supporting substrate, bonding layer, reflective medium layer and waveguide layer: BK7 glass wafer is polished and polished, and then deposited on the lower surface by plasma chemical vapor deposition method High reflective dielectric film (reflective rate>99%); then coat bonding epoxy resin on the surface of the above-mentioned reflective medium layer and the surface of the support substrate, and then form a structure comprising the support substrate, bonding layer, reflective medium layer and waveguide layer through a resin bonding process Multi-layer composite substrate, wherein the material of the supporting substrate is Si;

[0055] S2. Wafer grinding: grinding and polishing the surface of the glass wafer in the above-mentioned multilayer composite...

Embodiment 2

[0065] The second manufacturing method of a semiconductor laser light source module based on a planar waveguide type combiner comprises the following steps:

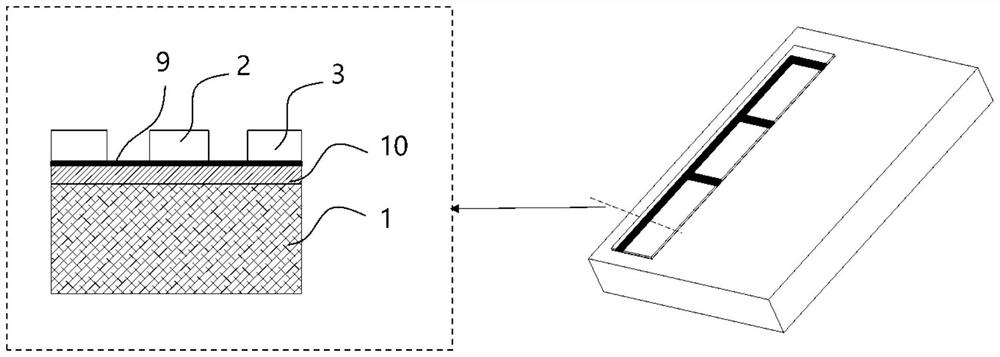

[0066] A1. Preparation of silicon-based supporting substrate containing metal layer: as Figure 9 As shown, firstly, an electrode groove 18 and an optical waveguide multiplexing structure installation groove 17 are formed on the silicon substrate 12 through an etching process, and then a laser welding metal film layer 19 and an electrode film layer 16 are formed through a deposition and etching process;

[0067] A2. Preparation of optical waveguide multiplex structure: prepare a multi-layer composite substrate including a supporting substrate, a bonding layer, a reflective medium layer and a waveguide layer by bonding and deposition processes, and then prepare an optical waveguide line pattern by grinding and etching. The waveguide multiplexing structure makes the thickness of the waveguide layer 60±5μm; finally, by cutt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com