Automatic die casting machine for producing grid of accumulator

An automatic plate and battery technology, applied in the field of pressure casting equipment, can solve the problems of short service life of batteries, rough surface of semi-finished products, unsatisfactory discharge effect, etc., and achieve the effect of prolonging service life, high degree of automation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

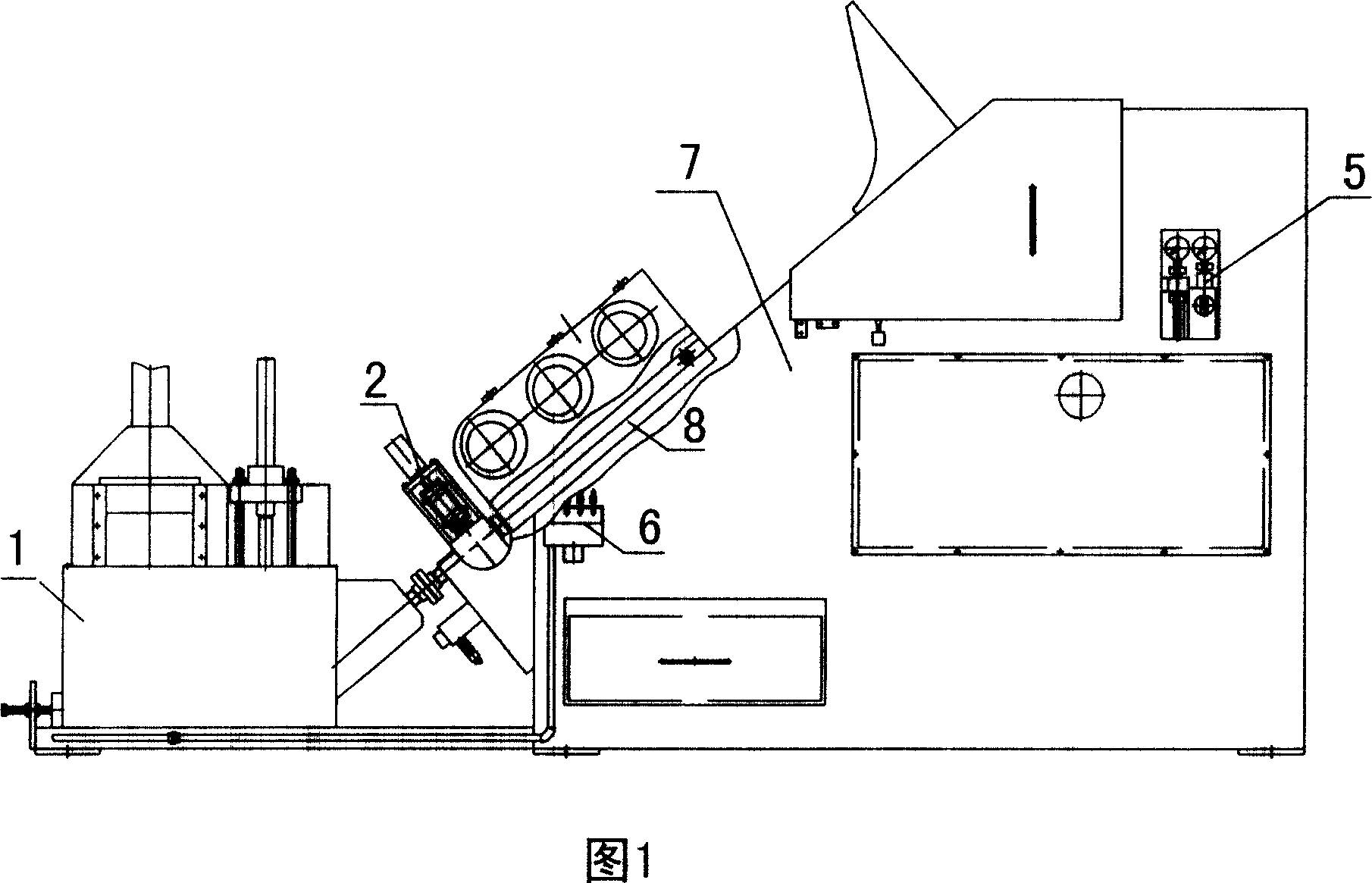

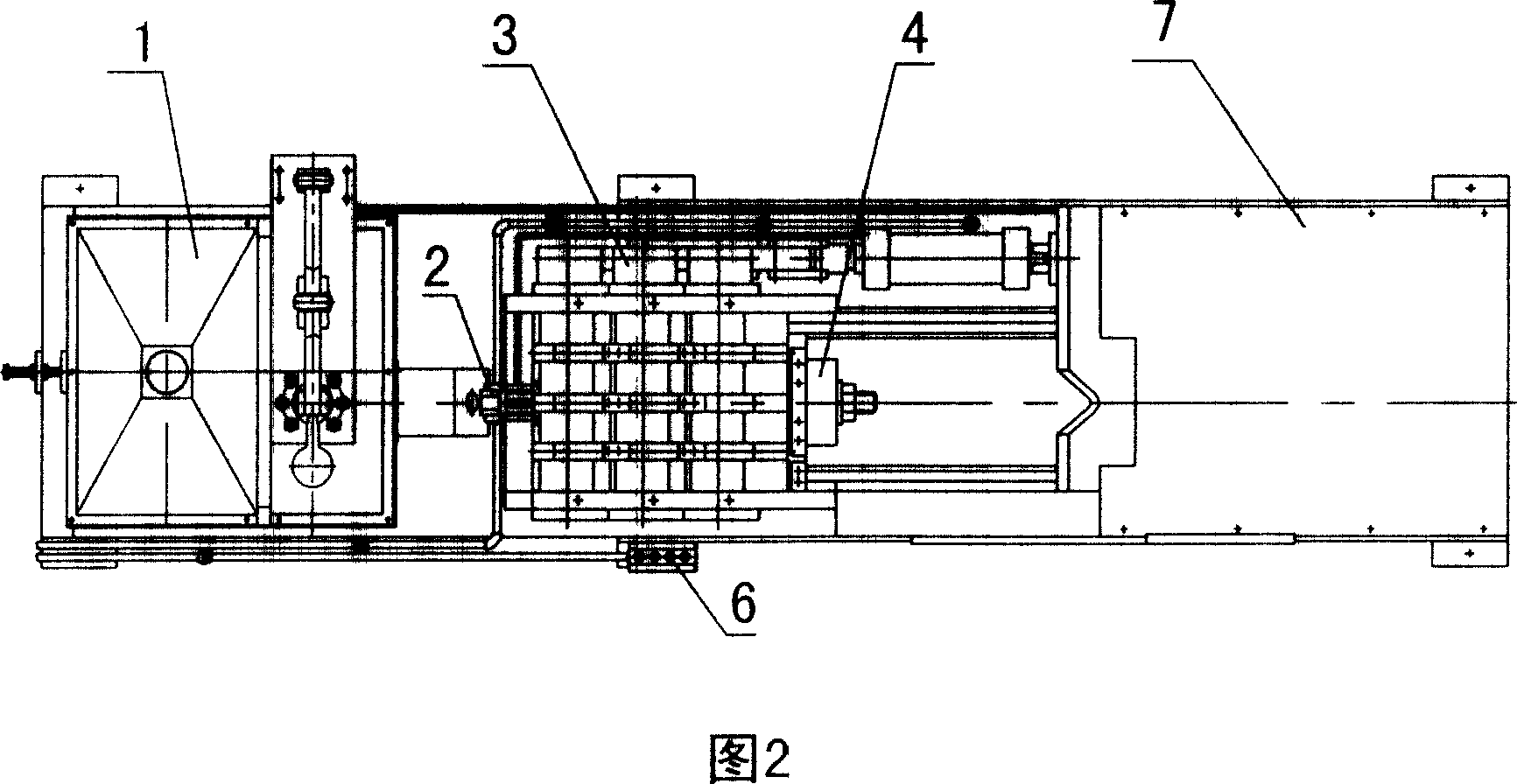

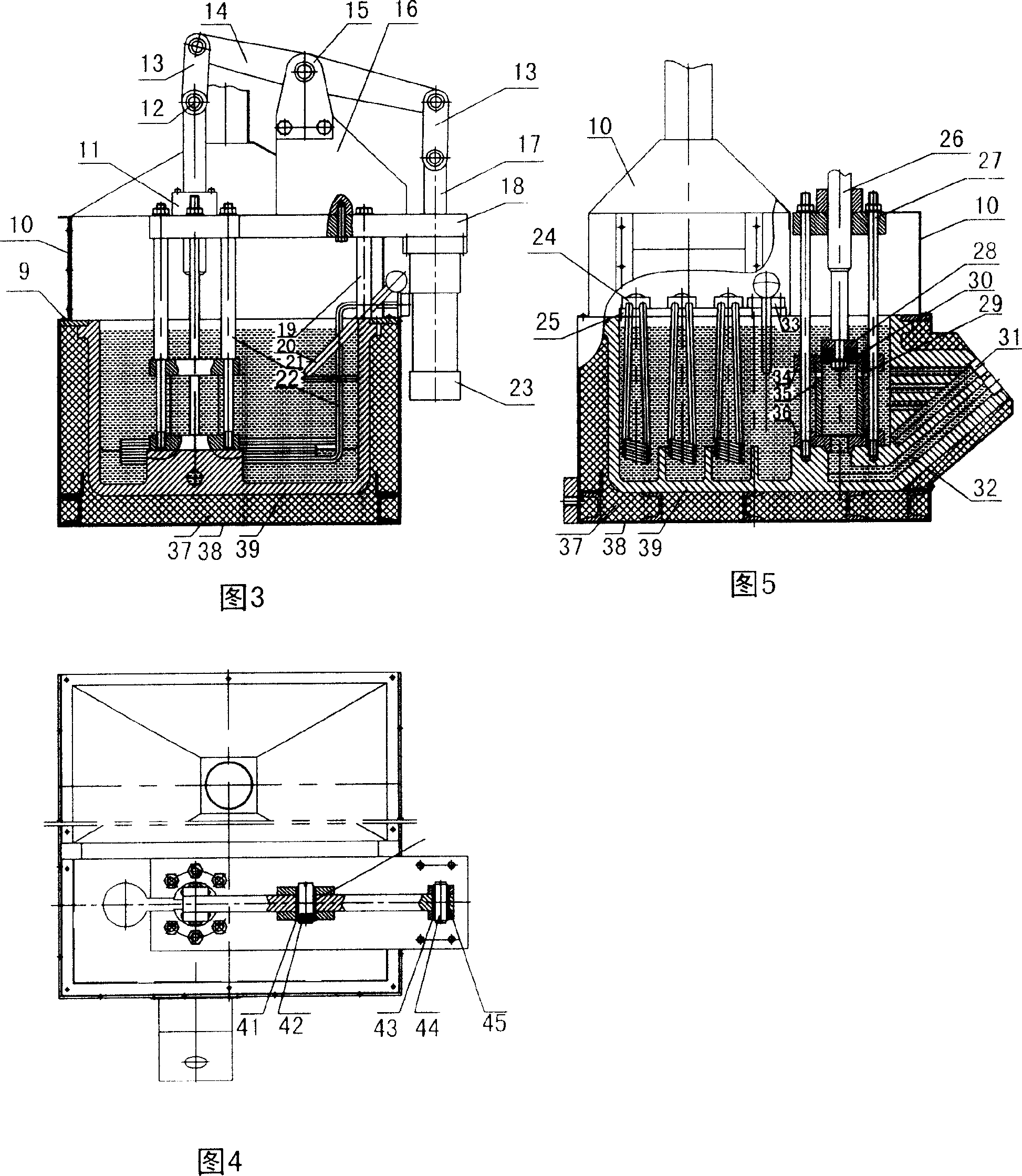

[0038] The whole machine of the present invention is shown in Figure 1 and Figure 2 and includes a lead pot part 1, a nozzle part 2, an eccentric pressing mechanism 3, a mold shifting mechanism 4, a hydraulic system 5, a water cooling system 6, a body 7, and a mold 8.

[0039] The first function of the lead pot part 1 is to melt the metal lead used to manufacture the product. Secondly, the hydraulic oil output from the hydraulic station drives the die-casting oil cylinder 23 installed in the lead pot part to complete the reciprocating motion. The die-casting oil cylinder pushes the lead liquid pump to melt. The resulting metallic lead is injected into the mold 8 through the runner 32 and the nozzle part 2 to produce a product that meets the requirements.

[0040] The power of the motor used in the hydraulic station is 5.5KW, which is used to drive the low-noise vane pump (model PV2R1F-23-F-RAA-F). The electrical control box (not shown in the figure) is used to control the die-cast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com