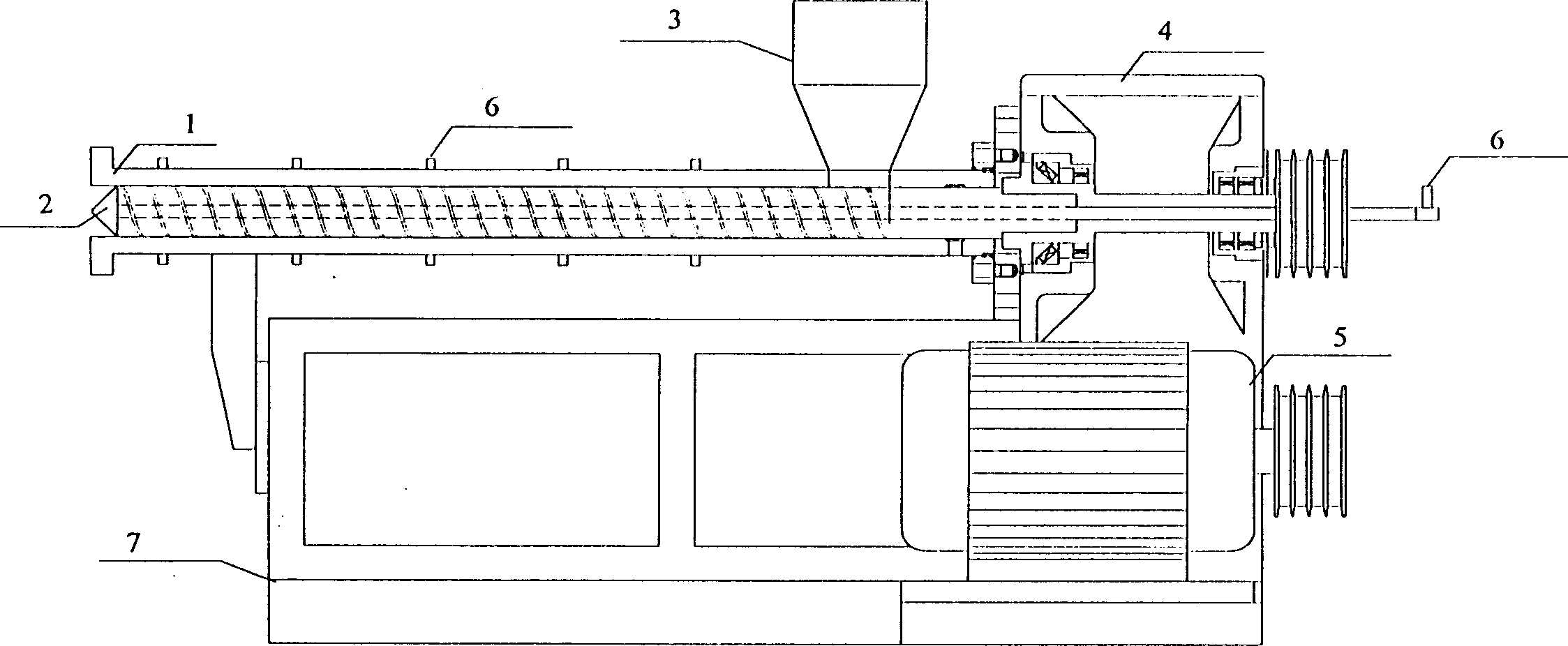

Super high-pressure single screw extruder

A single-screw extruder, ultra-high pressure technology, applied in the field of plastic machinery, can solve the problems of unstable profile quality of PVC plastic doors and windows, dare not use PVC plastic windows, and the surface of the profile is loose and not resistant to dirt, etc. Degradation phenomenon, broaden the scope of use, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: granulation with ultra-high pressure single-screw extruder

[0020] Work content: PVC plastic window profiles are made of powder into pellets

[0021] Recipe: PVC 100kg CPE 10kg ACR 2kg

[0022] Lead salt stabilizer 1.5kg lubricant 1.5kg calcium carbonate 15kg

[0023] Carbon black 0.5kg Iron oxide red 1.2kg Iron oxide yellow 0.8kg

[0024] Extruder diameter 120mm screw compression ratio 120 (0.2mm to 24mm)

[0025] Screw speed 1000 r / min Motor power 40KW

[0026] Operation process: Preheat the barrel of the extruder with a mobile heater. When the preheating temperature is heated to the processing temperature required by the chemical material, turn off and remove the heating device, and start the main motor of the extruder. Turn on the metering feeder to add chemical materials from the hopper, turn on the cooling device, and control the working temperature of the extruder within the processing temperature range required by the chemical materials by con...

Embodiment 2

[0028] Embodiment 2: extrusion molding with ultra-high pressure single-screw extruder

[0029] Work content: Carry out extruding molding material with the pellet that embodiment 1 makes

[0030] Extruder diameter 65mm screw compression ratio 10 (0.6mm to 6mm)

[0031] Screw speed 78 rev / min Motor power 20KW

[0032] Operation process: Preheat the barrel of the extruder with a mobile heater. When the preheating temperature is heated to the processing temperature required by the chemical material, turn off and remove the heating device, and start the main motor of the extruder. Turn on the metering feeder to add chemical materials from the hopper, turn on the cooling device, and control the working temperature of the extruder within the processing temperature range required by the chemical materials by controlling the amount of feeding and cooling.

[0033] The passing time of 42kg chemical material per hour in the high temperature zone is 16 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com