Method for bleaching fibrous materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

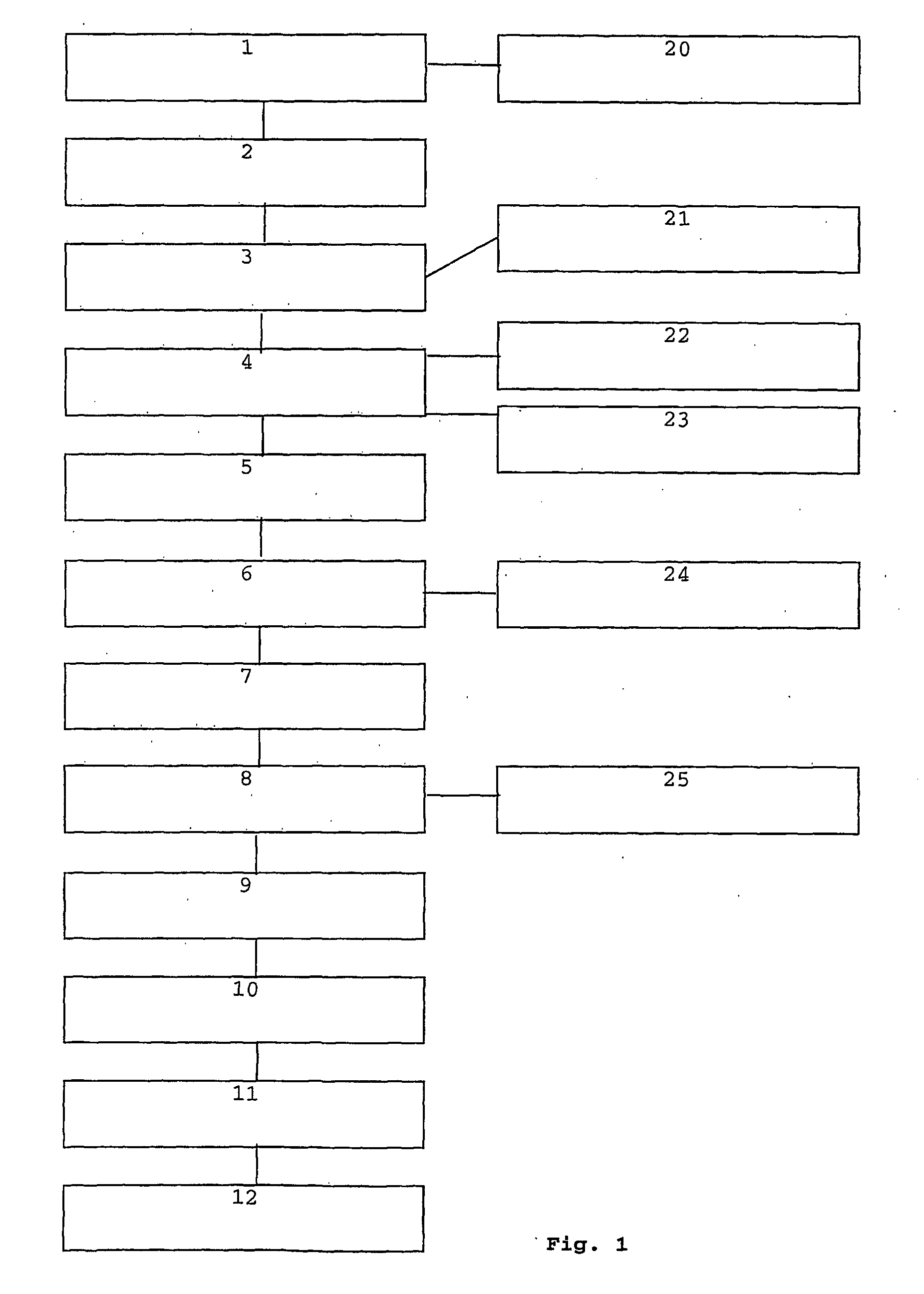

Image

Examples

Embodiment Construction

[0066] The executive example shown hereinafter illustrates four practical bleaching tests using mechanical wood pulp which was bleached with the method according to the present invention.

[0067] Here, the three tests differentiate themselves amongst other things in the amount of active bleaching agent used, here hydrogen peroxide (H2O2), and in the amount of added lime or water glass. The exact amounts used can be obtained from Table 1: Amounts used.

TABLE 1Amounts usedTest 1Test 2Test 3Test 4H2O2 [50%]3.0%6.0%7.4%3.0%Lime [17%]2.2%3.4%3.8%2.2%Water glass0.9%2.2%3.0%0.9%Mixing unitHighDoubleHighHighconsistencyshaftconsistencyconsistencymixermixermixermixerMaterial density 26%20-25% 26%˜17.5% Temperature65° C.˜55° C.65° C.65° C.

[0068] A high consistency mixer (Kamyr mixer) was used as the mixing unit in test series 1, 3 and 4 and a double shaft mixer was used as the mixing unit in test series 2.

[0069] The material density in test series 1 and 2 was 26%, in test series 2 it was 20 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com