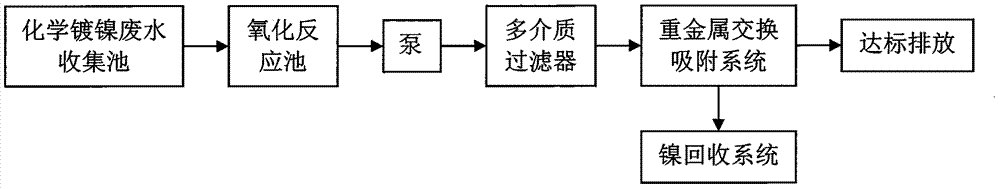

Method for treating electroless nickel-plating wastewater through combination of hydrogen-peroxide oxidation and ion exchange adsorption

An ion exchange adsorption, chemical nickel plating technology, applied in ion exchange water/sewage treatment, chemical instruments and methods, water/sewage treatment and other directions, can solve the problems of low nickel recovery rate, poor treatment effect, high treatment cost, and achieve The effect of avoiding secondary pollution, reducing treatment costs, and protecting loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

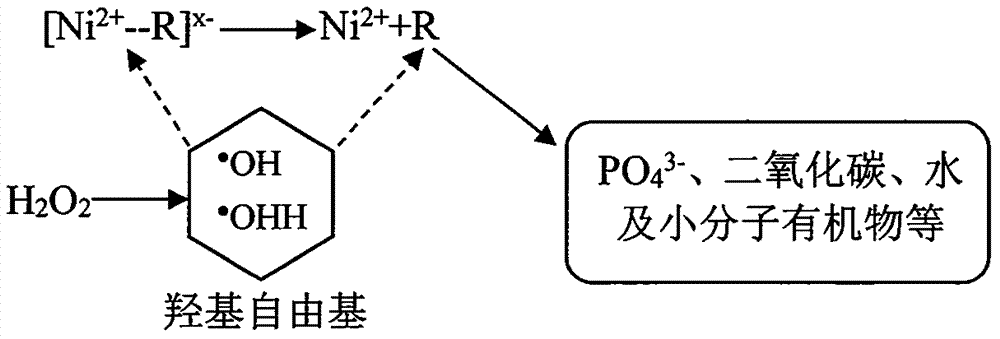

Method used

Image

Examples

example 1

[0031] Example 1: The preparation steps of this example include:

[0032] 1) 8L, 21.50mg / L electroless nickel plating wastewater, add 10mL, 98% sulfuric acid to adjust the pH value of the wastewater to 2.05;

[0033] 2) Add 28mL, 50% hydrogen peroxide, control the ORP value of the wastewater at 600mV-700mV, and stir for 3 hours;

[0034] 3) Weigh 100g of ion-exchange fibers and load them into two ion-exchange fiber columns on average;

[0035] 4) The electroless nickel plating wastewater after the oxidation reaction is treated by adsorption through the pump. Through continuous monitoring, the nickel concentration in the effluent is always lower than 0.1mg / L, which is fully up to the standard.

example 2

[0036] Example 2: The preparation steps of this example include:

[0037] 1) 1125L, 21.40mg / L, pH value of 1.50 electroless nickel plating wastewater, add 750g of sodium hydroxide to adjust the pH value of the wastewater to 2.68;

[0038] 2) Add 3.75L, 50% hydrogen peroxide, control the ORP value of the wastewater at 600mV-700mV, and stir for 3 hours;

[0039] 3) Weigh 10kg of ion exchange fibers and load them into 2 ion exchange fiber columns on average;

[0040] 4) The electroless nickel plating wastewater after the oxidation reaction is treated by adsorption through the pump. Through continuous monitoring, the nickel concentration in the effluent is always lower than 0.1mg / L, which is fully up to the standard.

[0041] 5) Regenerate the adsorbed ion-exchange fiber with an appropriate amount of regenerant, and add 30 g of oxalic acid to the concentrated solution to form a nickel oxalate precipitate;

[0042] 6) After the nickel oxalate precipitate is press-filtered, it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com