General-purpose machine for recycling, returning and binding stalks

A baler and straw technology, which is applied in the field of straw general-purpose recycling and baling machines, can solve the problems of low automation, inability to recycle and return baled straw production efficiency, etc., to save energy and protect water and land loss , Increase the effect of organic fertilizer ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

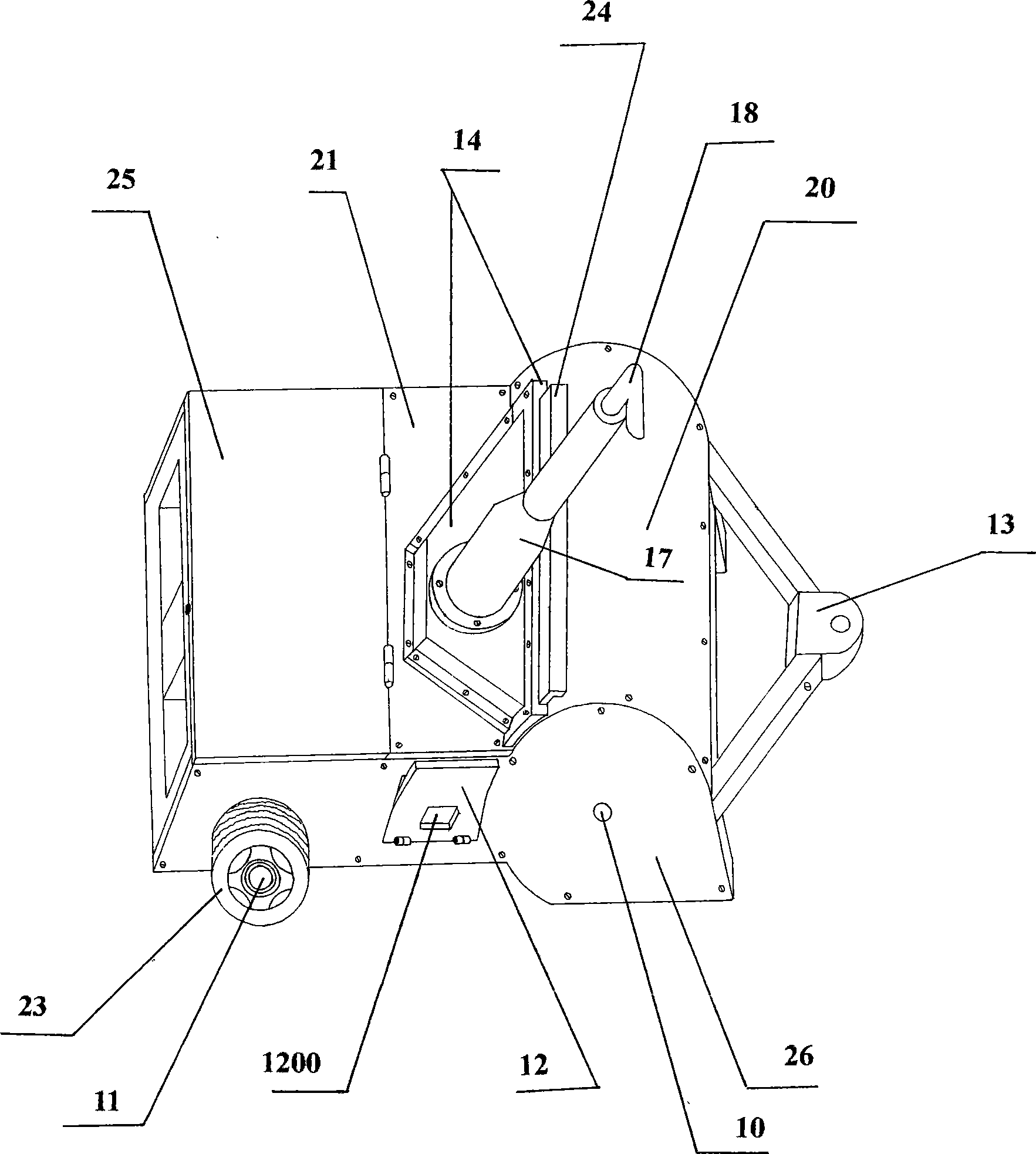

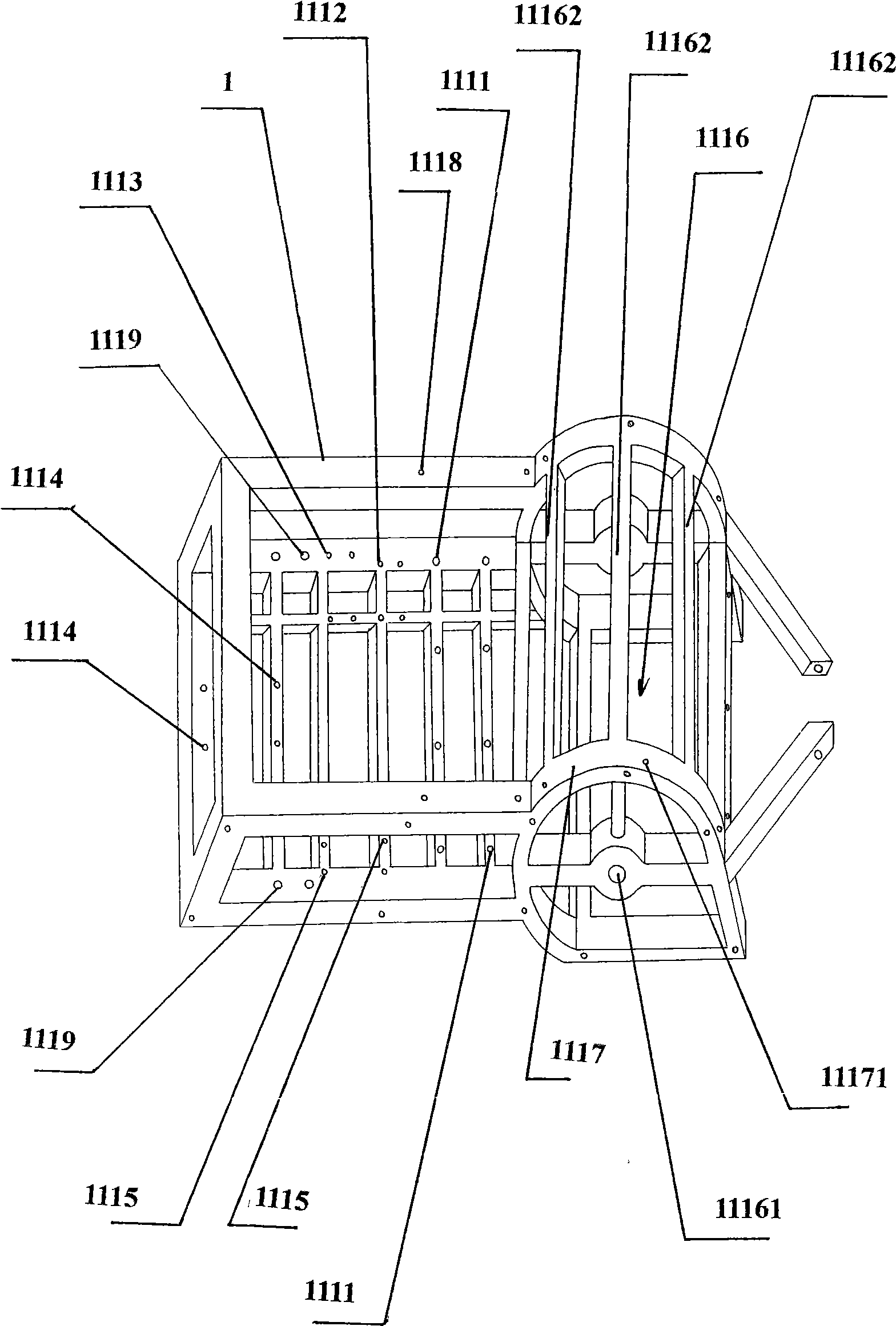

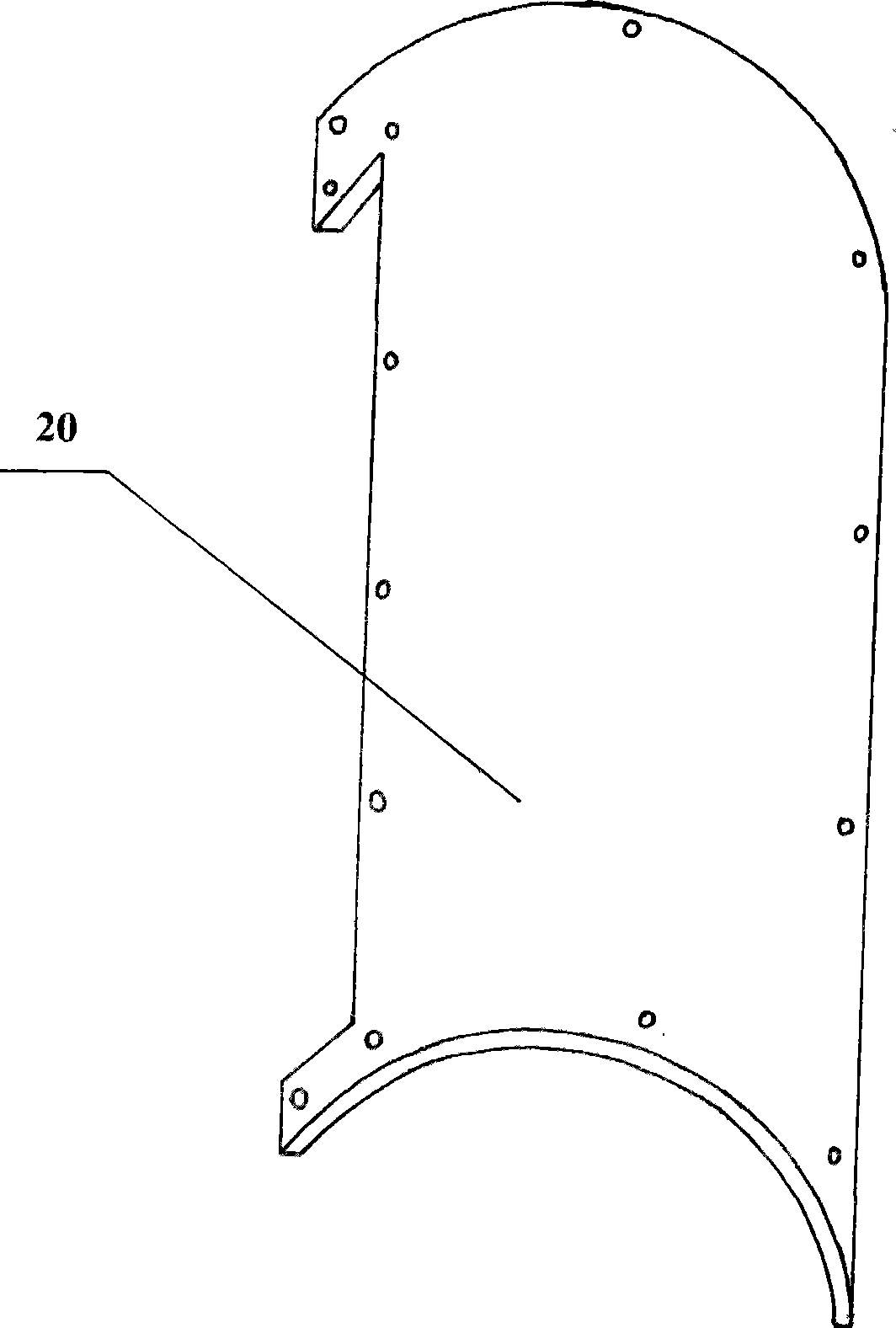

[0021] Please refer to Figures 1 to 13 As shown, the embodiment of the present invention includes a walking frame body 1, an extrusion body 2, an exhaust fan 3, an automatic cutting machine 4, a motor 5, a reducer 6, a power generation diesel engine 7, a row of knives 8, a cutter 9, and a front axle 10 , rear axle 11, supporting plate 12, traction block 13, shell 14, chain wheel 15, chain 16, base 17, outlet tube 18, protective cover 19, upper shell 20, front plate 21, extrude cone 21, road wheel 23, Baffle plate 24, cover 25, side plate 26 etc. are formed; Walking frame body 1 is provided with square space, and the crossbeam in the square space is provided with the corresponding hole 1111 that runs through from bottom to top with screw rod. It is fixed in the threaded hole provided at the bottom of the extruded body 2; the cross beam in the space is provided with a corresponding hole 1112 through up and down, and the screw rod is used to pass through the hole and tighten the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com