Control mechanism for opening and closing heating furnace door

An opening and closing mechanism and a heating furnace technology are applied in the field of heating furnaces, which can solve the problems of long opening and closing time, inconvenient maintenance of heating furnaces, and unfavorable cooperative use, etc., and achieve the effects of simple structure, low cost and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

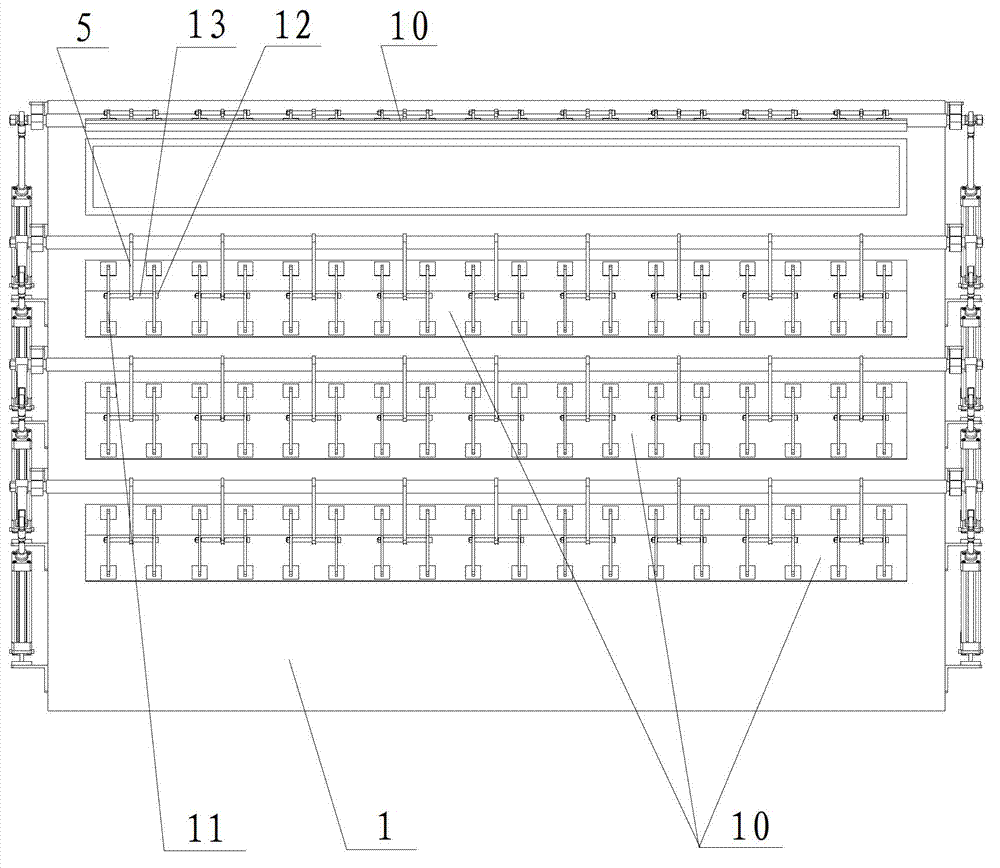

[0020] see figure 1 , the front of heating furnace 1 is arranged up and down and is provided with many fan furnace doors 10, and the outer surface of every fan furnace door 10 is uniformly installed many pairs of handles 11, and the middle part of every pair of handles 11 is connected with a rotating shaft 12 respectively. Each furnace door 10 is respectively connected with an opening and closing mechanism of the present invention.

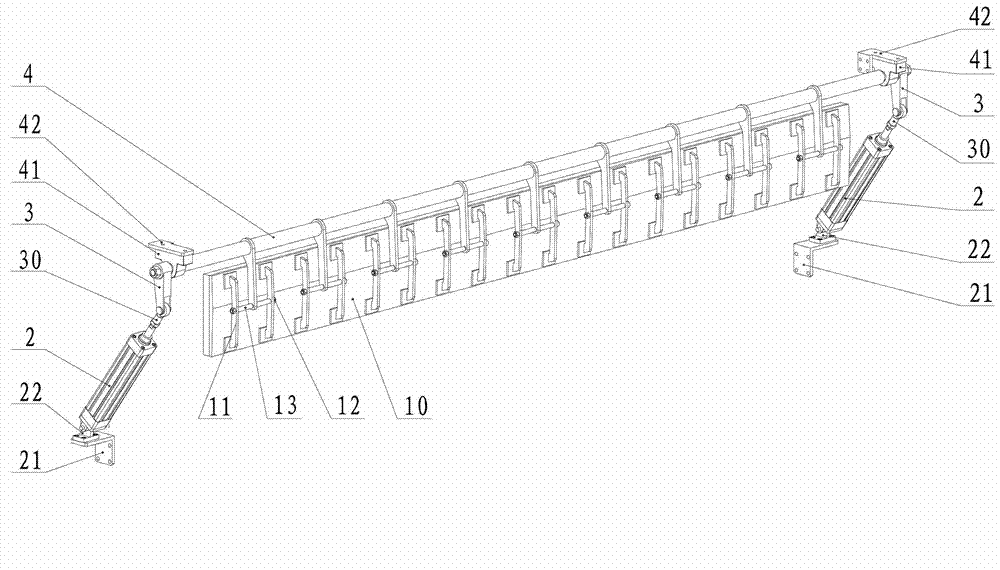

[0021] see again figure 2 , the opening and closing mechanism of the heating furnace door of the present invention comprises a pair of driving cylinders 2, a pair of cylinder rotating arms 3, a furnace door rotating arm 4 and a plurality of furnace door bracing arms 5, wherein:

[0022] A pair of driving cylinders 2 are installed on both sides of the heating furnace 1 through a cylinder mounting seat 21 and an earring seat 22 respectively; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com