Composite fibre for substituting asbestos

A composite and fiber technology, applied in fiber type, fiber treatment, short fiber formation, etc., can solve the complex spinning process of sea-island structure fibers, the degree of fibrillation is difficult to meet the needs of fine particles, and the fibers are difficult to disperse evenly and other problems, to achieve the effect of avoiding easy entanglement, high cost performance, and inhibiting the loss of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

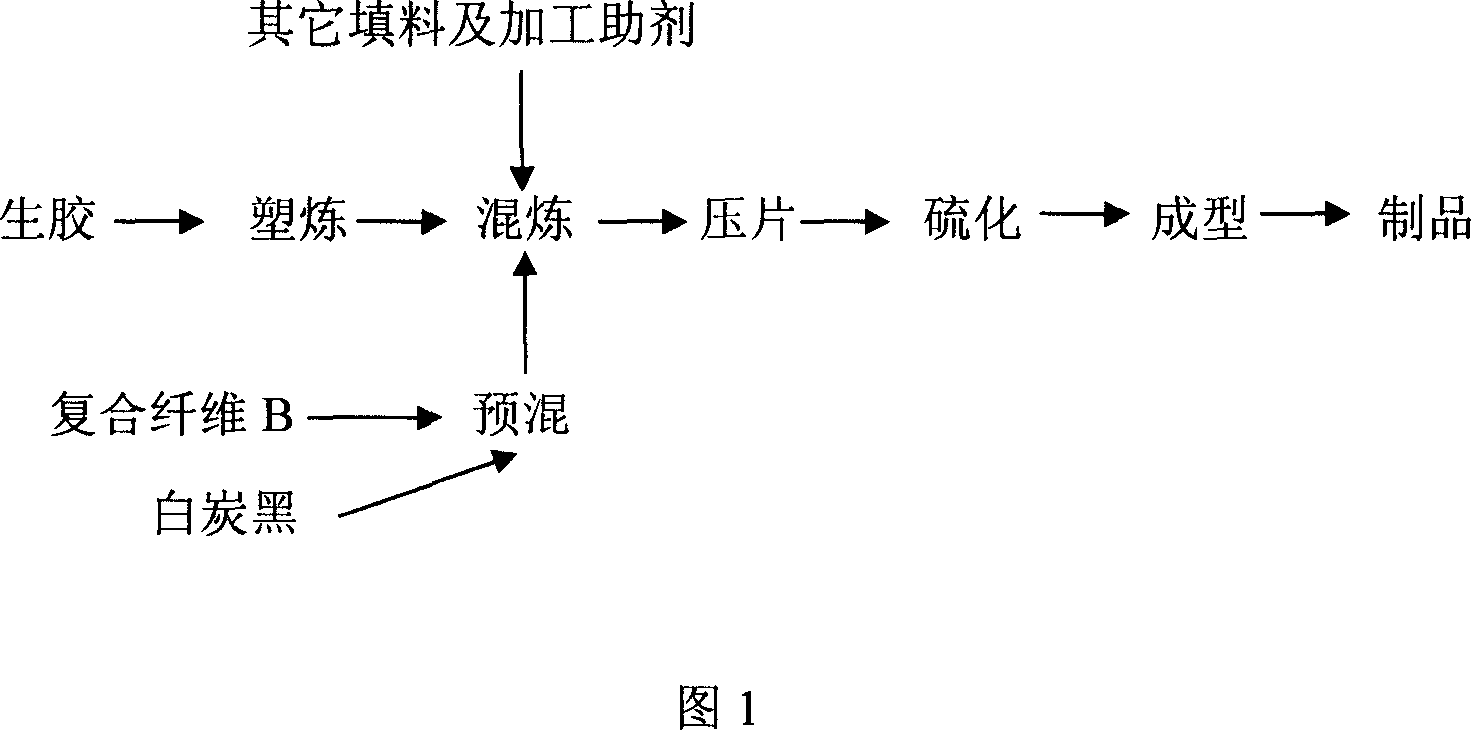

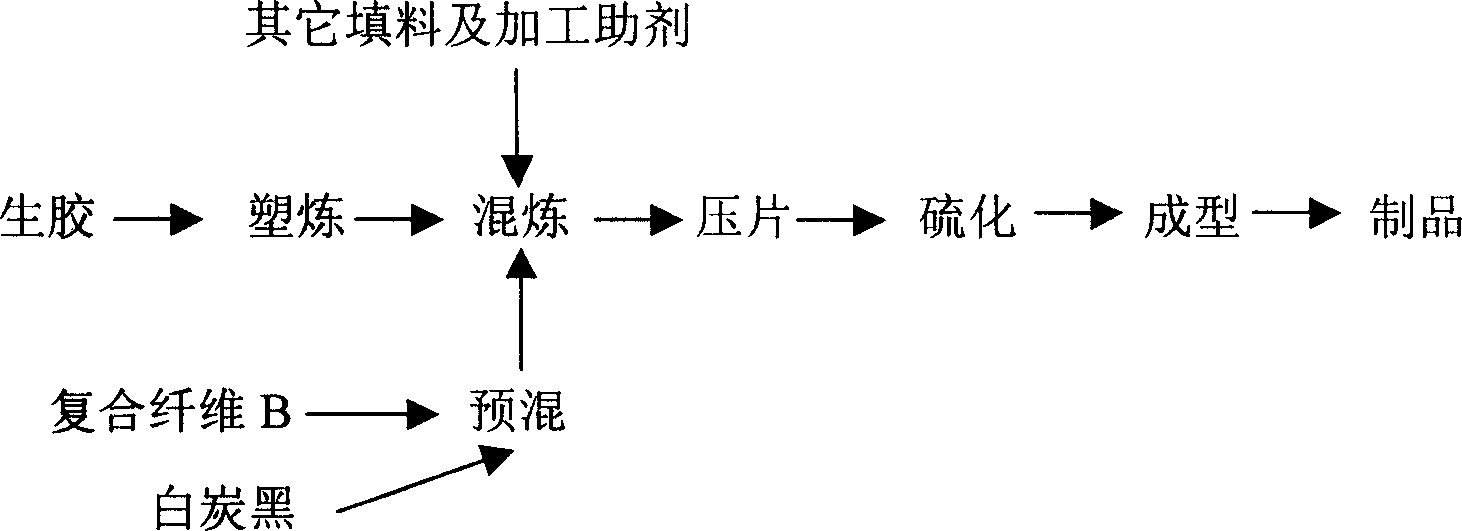

Method used

Image

Examples

example 1

[0021] Weigh 50 kg of polyacrylonitrile chopped fibers with a length of 5 mm and a denier of 3 d and 50 kg of polyacrylonitrile pulp with a length distribution of 2.0 ± 0.4 mm and a Canadian standard freeness of 225 ± 25 ml, and mix and disperse them in 4 t of water to form a suspension. Use 34s -1 After the suspension is forcedly dispersed and mixed at a high shear rate, it is centrifuged and dried to obtain a composite fiber A in which polyacrylonitrile pulp fibers are evenly coated on the surface of polyacrylonitrile chopped fibers.

example 2

[0023] Weigh 50kg of polyacrylonitrile chopped fibers with a length of 4mm and a denier of 1.5d and 50kg of polyacrylonitrile pulp with a length distribution of 2.0±0.4mm and a Canadian standard freeness of 225±25ml, mix and disperse them in 4t of water to form a suspension , using 34s -1 After forced dispersion and mixing of the suspension at a high shear rate, centrifugal dehydration and drying are performed to obtain a composite fiber B in which polyacrylonitrile pulp-like fibers are uniformly coated on the surface of polyacrylonitrile chopped fibers.

example 3

[0025] Weigh 75kg of polyvinyl alcohol polyacrylonitrile chopped fibers with a length of 6mm and a denier of 1.5d and 25kg of polyacrylonitrile pulp with a length distribution of 2.0±0.4mm and a Canadian standard freeness of 225±25ml, mix and disperse them in 4t of water To form a suspension, take 34s -1 After the suspension is forcedly dispersed and mixed at a high shear rate, it is centrifugally dehydrated and dried to obtain a composite fiber C in which polyacrylonitrile pulp fibers are uniformly coated on the surface of polyvinyl alcohol chopped fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com