Nanometer tin diselenide/graphene composite material and its preparation method and use

A technology of tin diselenide and composite materials, applied in the field of materials science, can solve the problems of difficult to control the shape, lack of synthesis methods, high toxicity and high pressure, etc., and achieve the effect of uniform shape, small size, and prevention of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

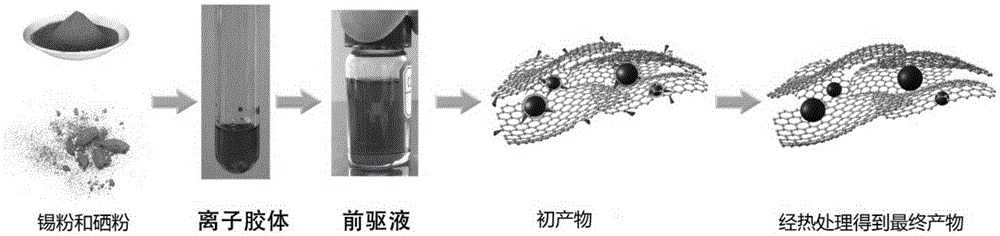

[0072] The preparation of embodiment 1 sample

[0073] a) Mix tin powder, selenium powder, and ionic liquid according to a certain ratio of substances, seal them in a quartz microwave reaction tube with a volume of 10 mL, and react at a constant temperature at a certain temperature under microwave heating conditions for a period of time, and then naturally cool down to room temperature , add 15mL of N-methylpyrrolidone to disperse, fully stir and filter, keep the filtrate to obtain the precursor solution containing selenostannate nanoparticles.

[0074] b) Disperse 200 mg of graphene oxide powder in 5 mL of deionized water, ultrasonically disperse and add 20 mL of a mixed solution of ethanol and NMP (the volume ratio of ethanol to NMP is 1:1), and ultrasonically again for 30 min to make the dispersion uniform.

[0075] c) Add the precursor solution prepared in step a) dropwise into the dispersion obtained in step b) while stirring vigorously, stir vigorously for 30 minutes to ...

Embodiment 2

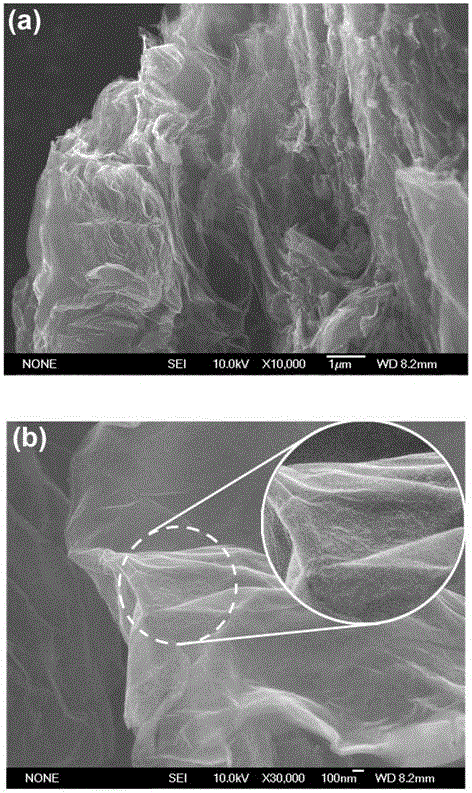

[0080] The characterization of embodiment 2 sample

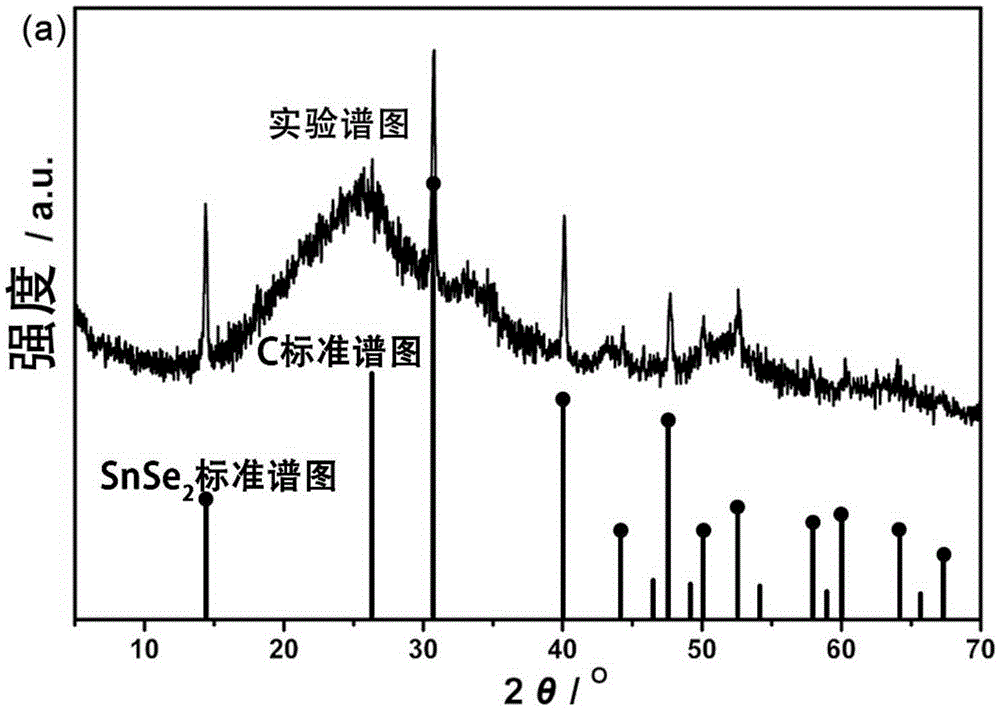

[0081] Adopt X-ray powder diffraction to the sample 1 that obtains in embodiment 1 # ~Sample 5 # Characterized to sample 1 # is a typical representative, and its XRD spectrum is as follows figure 2 shown, sample 2 # ~Sample 5 # The XRD spectrum and figure 2 Similar, that is, the positions of the diffraction peaks are basically the same, and the peak intensities of different samples are slightly different. Depend on figure 2 It can be seen that the diffraction peaks of the obtained product are consistent with those of crystalline SnSe 2 The standard diffraction spectra of the phases are basically consistent, and there are still some amorphous C phases, which should come from the thermally reduced graphene oxide substrate. According to this, it can be proved that the obtained product is SnSe 2 Composite products with graphene.

[0082] Adopt X-ray photoelectron energy spectrogram (XPS) to the sample 1 that obtains...

Embodiment 3

[0086] Embodiment 3 is tested to lithium ion cyclic voltammetry

[0087] Take sample 1 # As a typical representative, its cyclic voltammetry curve is tested, as follows:

[0088] The prepared sample, conductive carbon black, and binder polyvinylidene fluoride (abbreviated as PVDF, the mass percentage of polyvinylidene fluoride in the binder is 10%) are formulated in a weight ratio of 8:1:1 After making slurry. Evenly coated on the surface of copper foil of the negative electrode current collector with a thickness of 9 μm, then dried under vacuum at 120°C, sliced, pressed into tablets, and weighed to obtain the negative electrode sheet. Ethylene carbonate (abbreviated as EC) and diethyl carbonate (abbreviated as DEC) were uniformly mixed at a volume ratio of EC:DEC=1:1 to obtain a non-aqueous organic solvent. Addition of LiPF to non-aqueous organic solvents 6 , to get LiPF 6 A solution with a concentration of 1mol / L is the electrolyte. A half-cell was assembled in a glove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| First discharge capacity | aaaaa | aaaaa |

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com