High-speed enhanced ultraviolet silicon selective avalanche photodiode and manufacturing method thereof

An avalanche photoelectric, enhanced technology, applied in circuits, electrical components, semiconductor devices, etc., to achieve the effect of shortening diffusion time, improving selectivity, and improving responsivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will refer to the attached Figure 2-6 The present invention is described in detail:

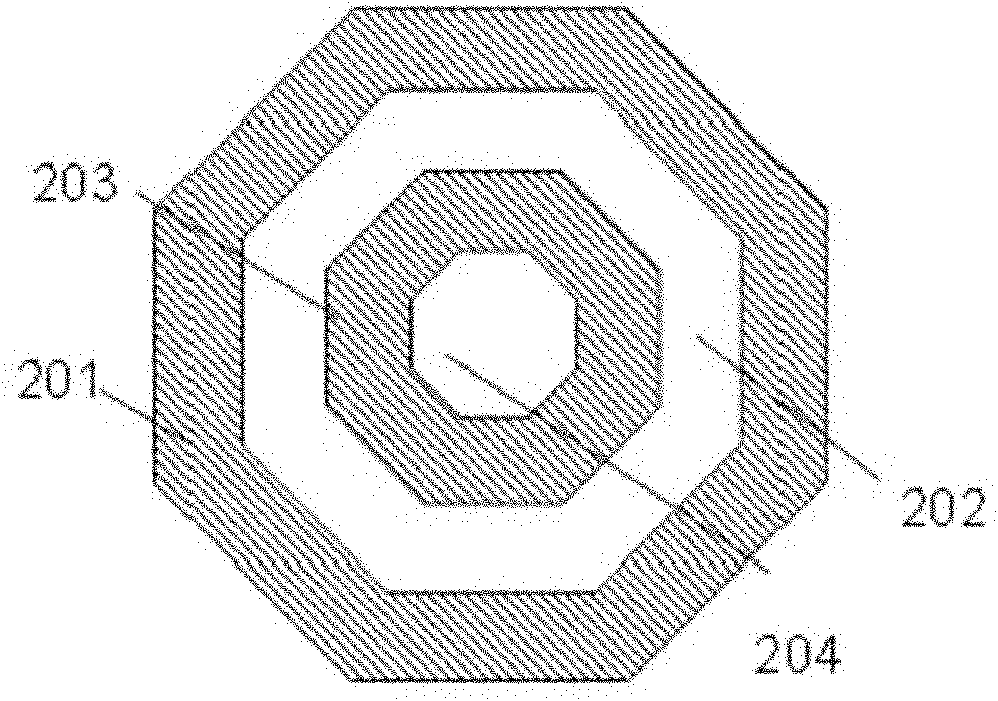

[0030] figure 2 It is the appearance shape of a single regular octagonal photosensitive region, and the pn junction formed between the P+ regions 201, 203 and n-well 202, 204 in the figure is a light absorption region. The number of concentric rings contained in the appearance shape of a single regular octagonal photosensitive area is not the standard as shown in the figure, and may include more regular octagonal concentric rings.

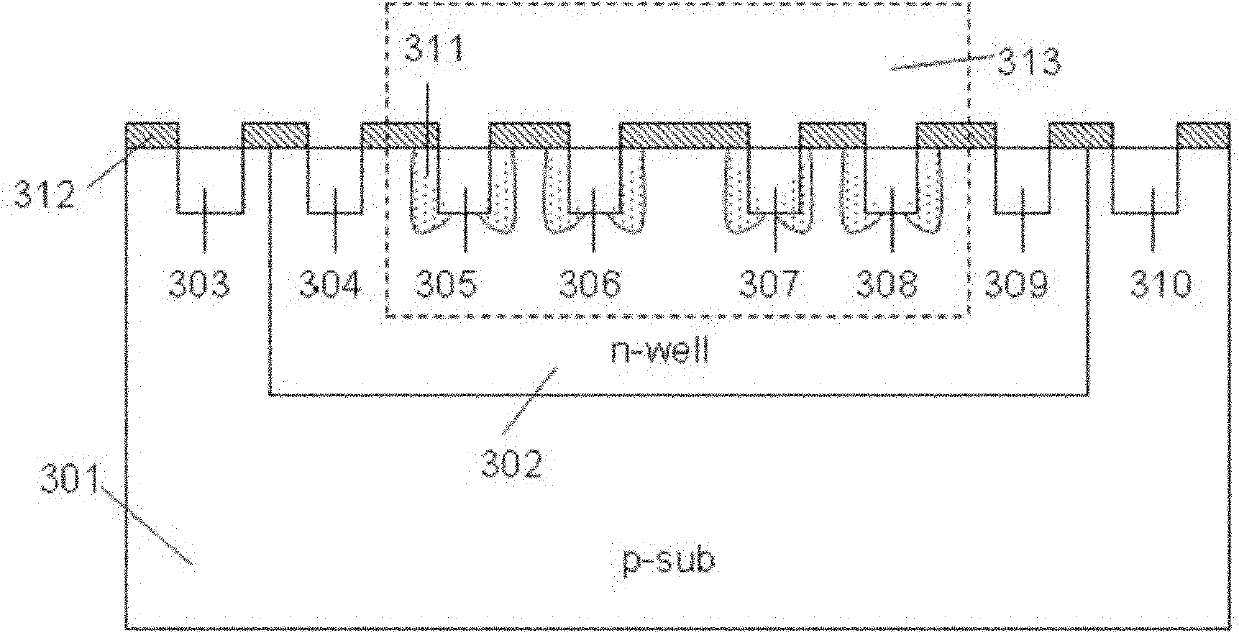

[0031] image 3 It is a structural diagram of the entire interior of a single regular octagonal concentric ring-shaped photosensitive region according to an embodiment of the present invention, and the dotted line box is a regular octagonal concentric ring-shaped photosensitive region. The P+ region in the N well is the anode of the structure, and the N+ region is the cathode of the structure. The P+ region in the P substrate is the read...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com