Preparation method for polyimide/oxidized graphene nanocomposite film

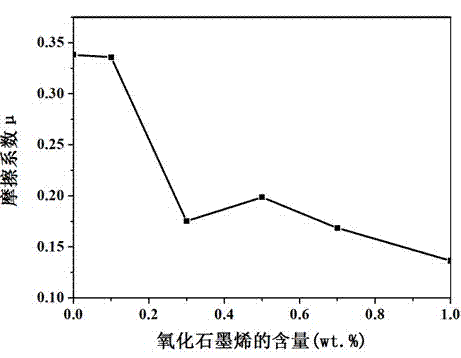

A polyimide and nanocomposite technology, applied in the field of preparation of functional polymer materials, can solve the problems of poor dispersion and poor wear resistance, and achieve the effects of simple process, improved tribological performance, and short preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

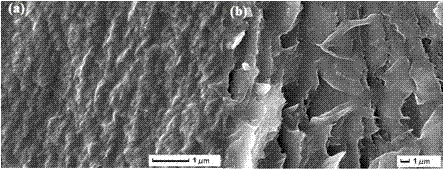

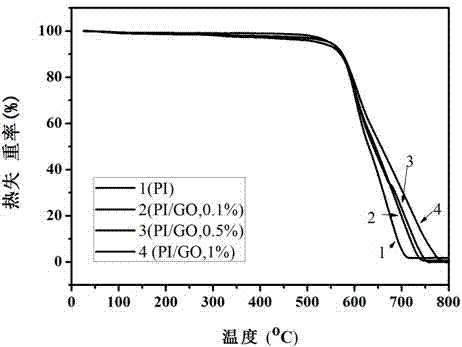

Image

Examples

Embodiment 1

[0024] (1) Preparation of graphene oxide:

[0025] Accurately weigh 3g of graphite and 1.5g of sodium nitrate, dissolve them together in 69ml of 98% concentrated sulfuric acid, stir mechanically for 30min in an ice-water bath, slowly add 9g of potassium permanganate, and wait until the potassium permanganate is fully dissolved , the temperature was raised to 35° C. for 1 hour to form a thick liquid. Add 69ml of distilled water dropwise, raise the temperature to 98°C, and react for 15 minutes. Pour the mixture into a mixture of 140ml distilled water, 20ml hydrogen peroxide (30%) and 400ml 20% hydrochloric acid. The mixture was filtered and centrifuged with 20% hydrochloric acid and distilled water and washed until neutral until the sulfate ion could not be detected with barium chloride, and then put into a vacuum drying oven at 40°C for 48 hours to prepare graphite oxide.

[0026] (2) Preparation of polyimide / graphene oxide nanocomposite film:

[0027] Weigh 0.010559g of gr...

Embodiment 2

[0029] (1) Same as (1) in Example 1

[0030] (2) Preparation of polyimide / graphene oxide nanocomposite film:

[0031] Weigh 0.031677g of graphene oxide, and ultrasonically disperse it in N, N′-dimethylformamide solvent, so as to obtain a suspension of graphene oxide flakes. 5g of 4,4'-diaminodiphenylsulfide was added to the mixed solution, and stirred under the protection of nitrogen to make it completely dissolved, and then a small amount of 5.559g of perphthalic anhydride was uniformly added to the solution several times, and the It was reacted in an ice bath for 2 hours to prepare a polyamic acid / graphene oxide composite solution. Coat the polyamic acid / graphene oxide composite solution on the glass mold, then put it in a blast drying oven at 60°C for 2 hours to remove the N, N′-dimethylformamide solvent, and then raise the temperature gradually in the blast drying oven , 100°C for 1h, 150°C for 30min, 200°C for 30min, 250°C for 30min, 300°C for 30min. After the imidizati...

Embodiment 3

[0033] (1) Same as (1) in Example 1

[0034] (2) Preparation of polyimide / graphene oxide nanocomposite film:

[0035] Weigh 0.052795g of graphene oxide, and ultrasonically disperse it in N-methylpyrrolidone solvent to obtain graphene oxide flake suspension. 5g of diaminodiphenylmethane was added to the mixed solution, and stirred under the protection of nitrogen to make it completely dissolved, then a small amount of 5.559g of biphenyltetracarboxylic dianhydride was evenly added to the solution several times, and it was placed in an ice bath. The reaction was carried out for 3 hours to prepare a polyamic acid / graphene oxide composite solution. Coat the polyamic acid / graphene oxide composite solution on the glass mold, and then put it in a blast drying oven at 60°C for 2 hours to remove the N-methylpyrrolidone solvent, then gradually increase the temperature in the blast drying oven at 100°C for 1h, 150°C for 30min, 200°C for 30min, 250°C for 30min, 300°C for 30min. After the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com