Modified PVDF membrane and preparation method thereof

A modified and viscous liquid technology, which is applied in the field of membrane separation technology and photocatalysis, can solve the problems of environmental pollution, ignoring catalyst recovery and recycling, etc., and achieve the effect of easy availability of raw materials, good application prospects, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

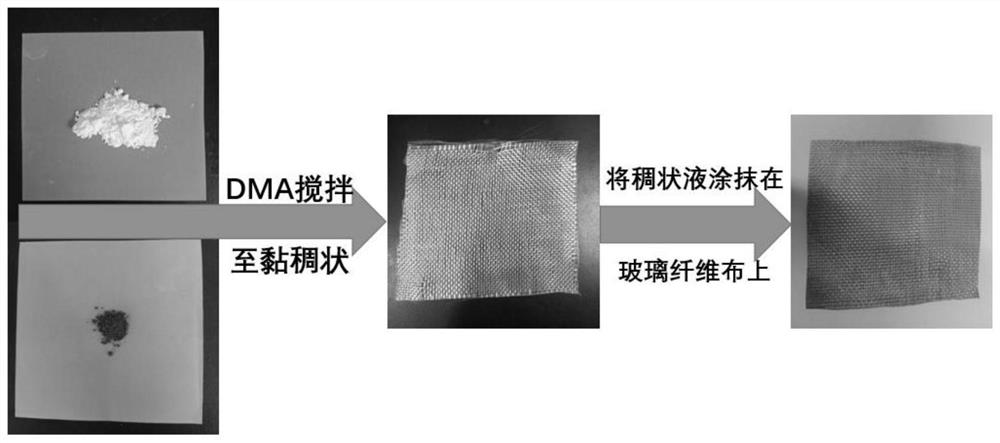

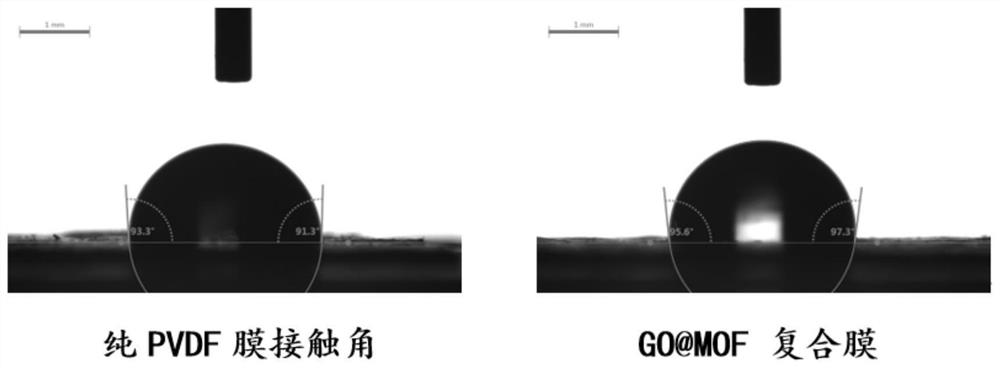

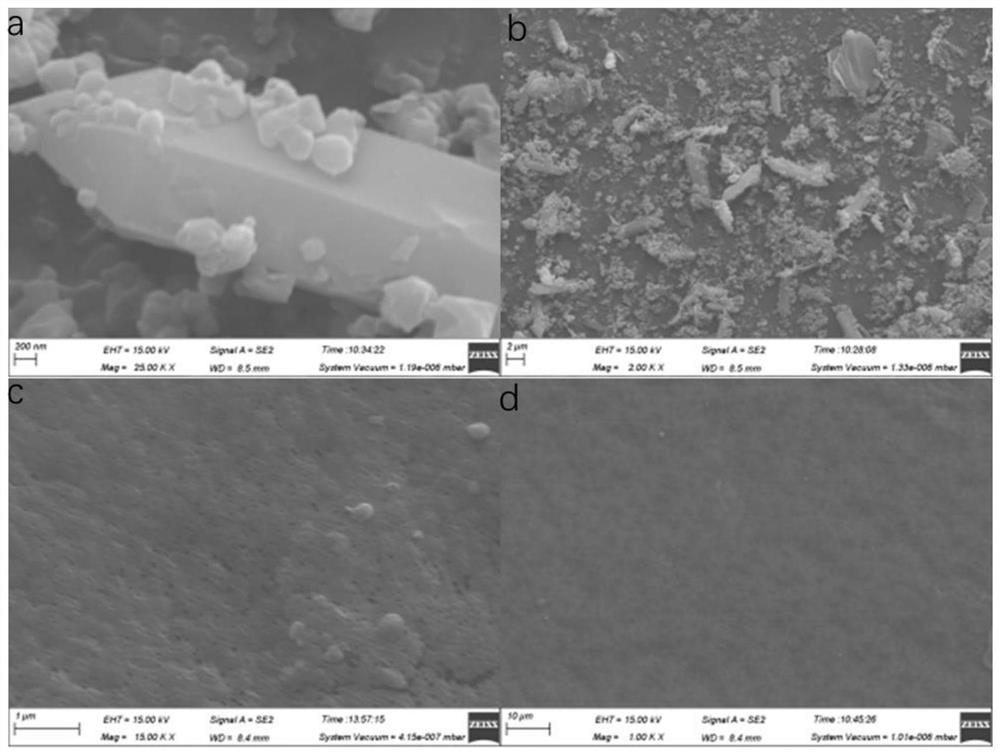

Method used

Image

Examples

Embodiment 1

[0044] Graphene oxide was prepared by the modified Hummers method, which was divided into three stages:

[0045] Low temperature stage: Dissolve 1.2g graphite powder and 0.5g sodium nitrate in 150ml mixed acid solution (135ml concentrated H 2 SO 4 +15ml concentrated H 3 PO 4 ), stir at below 20°C for 0.5h, keep the temperature below 20°C, then slowly add 7g of potassium permanganate, and stir for 1h;

[0046] Medium temperature stage: raise the temperature to 35°C, stir for 2 hours, then slowly add the solution to 150ml of ice water;

[0047] High temperature stage: raise the temperature to 90°C, after continuous heating for 20 minutes, the solution turns brownish yellow and produces red smoke, stop heating and add 5ml H 2 o 2 (concentration is 30%), until solution turns golden yellow;

[0048] The resulting solution was allowed to stand overnight, the supernatant was decanted, the lower turbid liquid was centrifuged (12000 rpm, 10 min), and the resulting solid was washe...

Embodiment 2

[0055] Preparation of emulsion

[0056] Preparation of oil-in-water emulsion: take 0.5g of gasoline, 0.05g of sodium dodecylsulfonate, and 1L of deionized water and stir and mix, put the mixture into an ultrasonic device, and ultrasonicate for 2 hours at room temperature to obtain uniformly emulsified oil-water Emulsion, the prepared emulsion is milky white and is oil-in-water type. After standing for 24 hours, the emulsion has no obvious change, indicating that the emulsified structure has stability.

Embodiment 3

[0058] Oil-Water Separation Experiment

[0059] Heavy oil: nitrobenzene, dichloromethane, chloroform, benzyl alcohol; light oil: toluene, cyclohexane, p-xylene, gasoline. Take 5ml of various organic phases and 40ml of water (stained by methylene blue) and mix them into a special device, see Figure 5 , calculate the oil flux of various organic substances, and compare the blank membrane with the composite membrane. Compared with the blank membrane, the oil-water separation effect of the composite membrane added with catalyst is significantly improved. The oil flux of nitrobenzene and chloroform is about 1.2×10 5 and 1.37×10 5 mg·m -2 h -1 . In order to test the recycling effect of materials, repeated tests were carried out with chloroform as the separation object.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com