Raw material composition and preparation method of sustained-release drought-resistant water-retention nutrient

A nutrient, slow-release technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve problems such as unreasonable coordination of elements and trace elements, insignificant effect of anti-stress film structure components, and poor durability and controllability of drought resistance. , to achieve the effect of alleviating plant physiological damage, improving the quality of agricultural products, and preventing bacterial infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

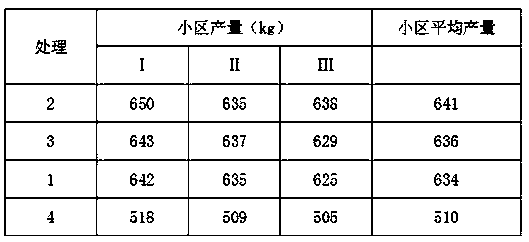

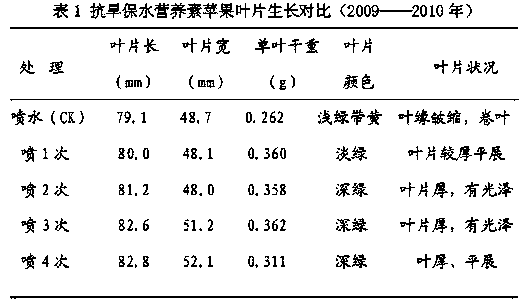

Examples

Embodiment 1

[0012] A slow-release drought-resistant and water-retaining nutrient is composed of the following raw materials in parts by weight: 580 kg of ammonium phytate, 90 kg of coated urea, 80 kg of phosphate fertilizer, 80 kg of ammonium phosphate, 22 kg of chitin, 5 kg of matrine, 20 kg of glauconite, and fulvic acid 70kg, amino acid 20kg, bone powder 20kg, rare earth 1kg, medical stone 12kg.

[0013] The ammonium phytate is ammonium phytate produced by sorting, purifying, fermenting, and extracting weathered coal, lignite, and cinders in a weight ratio of 2:1:1. The extraction process is as follows: weathering coal, lignite, and cinders with The weight ratio of 2:1:1 was washed and soaked with water at 50°C respectively, and then treated with warm fire at 60°C for 160 minutes, the extraction pressure was controlled at 345MPa, and the extraction time was 6h; then 5 times the amount of 45 % ethanol for room temperature leaching, leaching 3 times, 10 hours each time, combining the ext...

Embodiment 2

[0016] A slow-release drought-resistant and water-retaining nutrient is composed of the following raw materials in parts by weight: 637.2kg of ammonium phytate, 80kg of coated urea, 60kg of phosphate fertilizer, 60kg of ammonium phosphate, 25kg of chitin, 10kg of matrine, 25kg of glauconite, yellow rot Acid 60kg, amino acid 22kg, bone powder 30kg, rare earth 1.5kg, medical stone 12kg.

[0017] The ammonium phytate is ammonium phytate produced by sorting, purifying, fermenting, and extracting weathered coal, lignite, and cinders in a weight ratio of 2:1:1. The extraction process is as follows: weathering coal, lignite, and cinders with The weight ratio of 2:1:1 was washed and soaked with water at 50°C respectively, and then treated with warm fire at 60°C for 160 minutes, the extraction pressure was controlled at 345MPa, and the extraction time was 6h; then 5 times the amount of 45 % ethanol for room temperature leaching, leaching 3 times, 10 hours each time, combining the extra...

Embodiment 3

[0020] A slow-release drought-resistant and water-retaining nutrient is composed of the following raw materials in parts by weight: 650 kg of ammonium phytate, 150 kg of coated urea, 140 kg of phosphate fertilizer, 120 kg of ammonium phosphate, 30 kg of chitin, 25 kg of matrine, 40 kg of glauconite, and fulvic acid 80kg, amino acid 45kg, bone powder 35kg, rare earth 1.6kg, medical stone 40kg.

[0021] The ammonium phytate is ammonium phytate produced by sorting, purifying, fermenting, and extracting weathered coal, lignite, and cinders in a weight ratio of 2:1:1. The extraction process is as follows: weathering coal, lignite, and cinders with The weight ratio of 2:1:1 was washed and soaked with water at 50°C respectively, and then treated with warm fire at 60°C for 160 minutes, the extraction pressure was controlled at 345MPa, and the extraction time was 6h; then 5 times the amount of 45 % ethanol for room temperature leaching, leaching 3 times, 10 hours each time, combining t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com