Modified glauconite, and preparation method and applications thereof

A glauconite, modification technology, applied in the direction of chemical instruments and methods, other chemical processes, silicates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

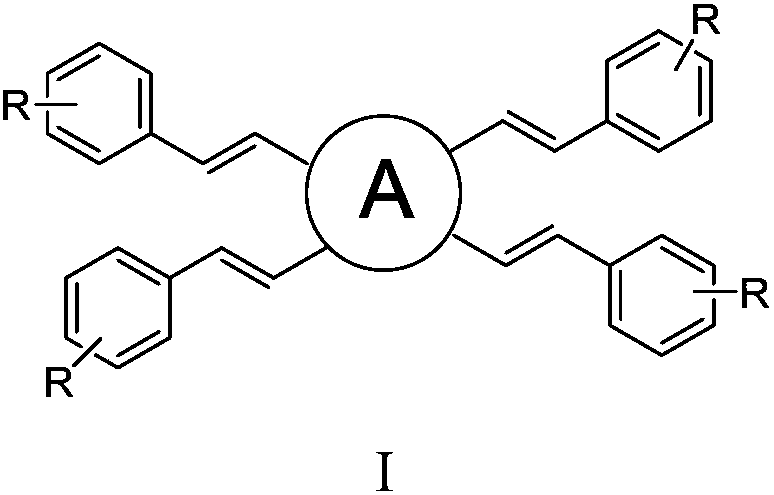

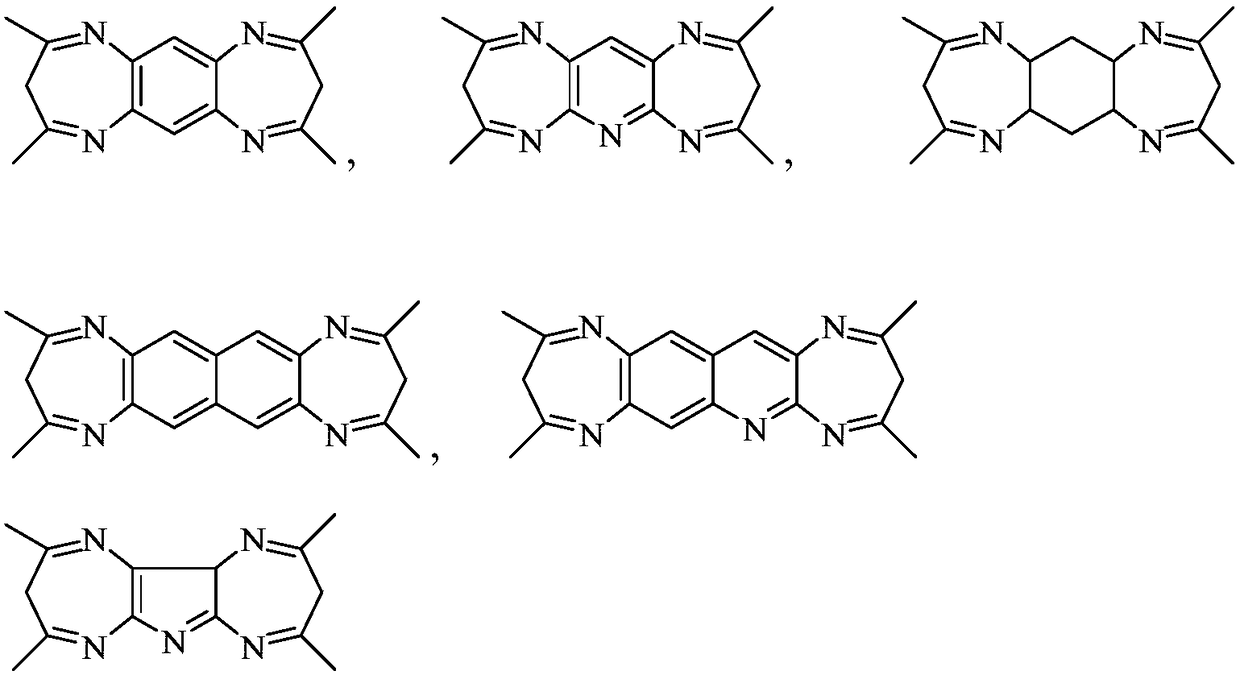

Image

Examples

Embodiment 1

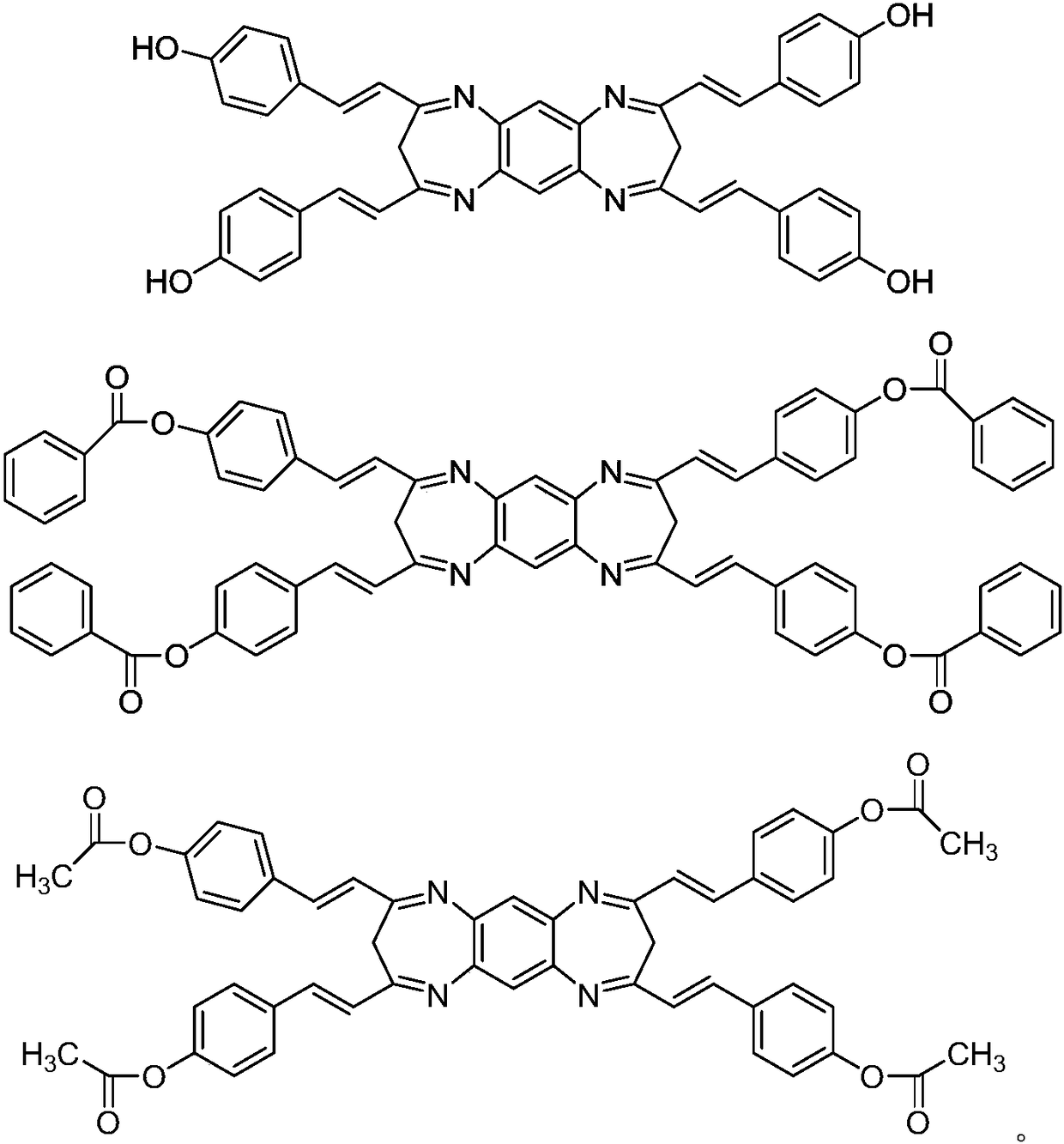

[0066] Add 1,2,4,5-benzenetetramine tetrahydrochloride (20mmol), 100mL glacial acetic acid and sodium acetate (40mmol) into the reaction vessel, stir, and slowly add dihydrochloride dissolved in 50 ml of glacial acetic acid Demethoxycurcumin (41mmol), reflux reaction, TLC monitoring reaction. After the reaction was complete, cool to room temperature and wash with saturated NaHCO 3 The solution was adjusted to pH about 8, extracted three times with dichloromethane, the organic layers were combined, MgSO 4 After drying and recrystallization from absolute ethanol, the compound of the following formula was obtained as a yellow powder solid with a yield of 76%.

[0067]

[0068] 1 H NMR (400MHz,DMSO)δ9.68(s,OH,4H),7.64(d,H,4H),7.45(s,CH,8H),6.95(d,H,4H),6.75(s,CH ,2H),6.59(d,H,8H),2.97(s,CH 2 ,4H).

Embodiment 2

[0070] The compound described in Example 1 (5 mmol), benzoyl chloride (21 mmol) and toluene solution (100 mL) were sequentially added to a dry reaction vessel. Stirring, reflux reaction, TLC monitoring reaction until the end. After cooling to room temperature, the reaction system was poured into an ice-water system, filtered with suction, the solid was recrystallized with ethanol, and dried to obtain the following compound as a flaky white solid with a yield of 62%.

[0071]

[0072] 1 H NMR (400MHz,DMSO)δ8.16(t,CH,8H),7.72(t,CH,4H),7.69(m,CH,8H),7.64(d,H,4H),7.62(m,CH ,8H),7.36(m,CH,8H),6.95(d,H,4H),6.75(s,CH,2H),2.97(s,CH 2 ,4H).

Embodiment 3

[0074] Using the reaction steps and conditions similar to Example 2, replacing benzoyl chloride with the corresponding raw material of acetyl chloride, the following compounds were prepared with a yield of 66%.

[0075]

[0076] 1 H NMR (400MHz,DMSO)δ7.64(d,H,4H),7.62(t,CH,8H),7.28(d,CH,8H),6.95(d,H,4H),6.75(s,CH ,2H),2.31(s,4CH 3 ,12H),2.97(s,CH 2 ,4H).

[0077] The preparation embodiment of modified glauconite

[0078] Heat 50kg of glauconite raw sand at about 350°C by microwave, crush it on a roller crusher, and remove dust. Then, under different magnetic field induction intensities, the samples were magnetically separated on a roller magnetic separator by leak weighing. At the same time, under the higher induction intensity, the next step is to sort the non-magnetic products with low induction intensity.

[0079] The material was crushed in a roll crusher to sieve the sample material with a particle size of less than 0.5 mm. Materials with a particle size greater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com