Glauconite-based composite heavy metal wastewater treatment porous material as well as preparation method and application thereof

A wastewater treatment and porous material technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult recycling, high difficulty of filtration and separation, and achieve good removal effect, significant market value, and effect on social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

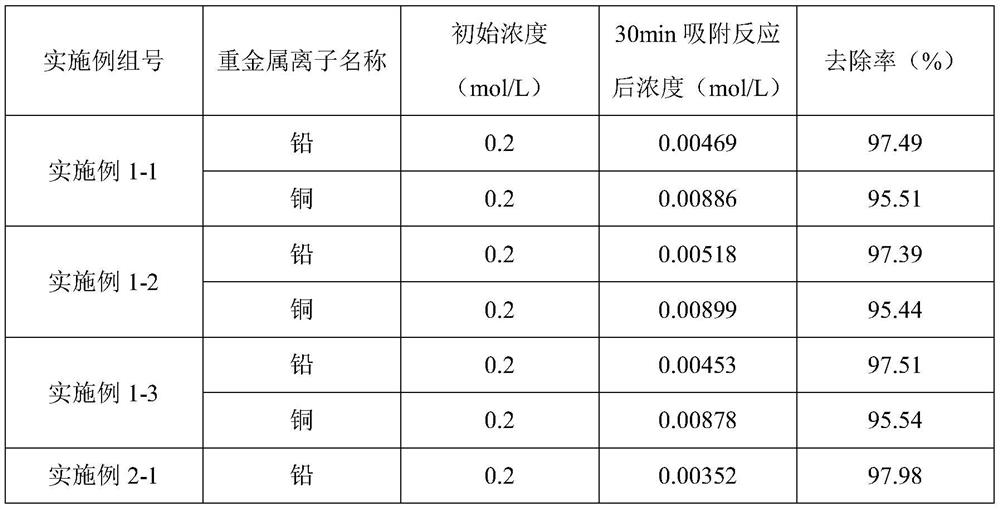

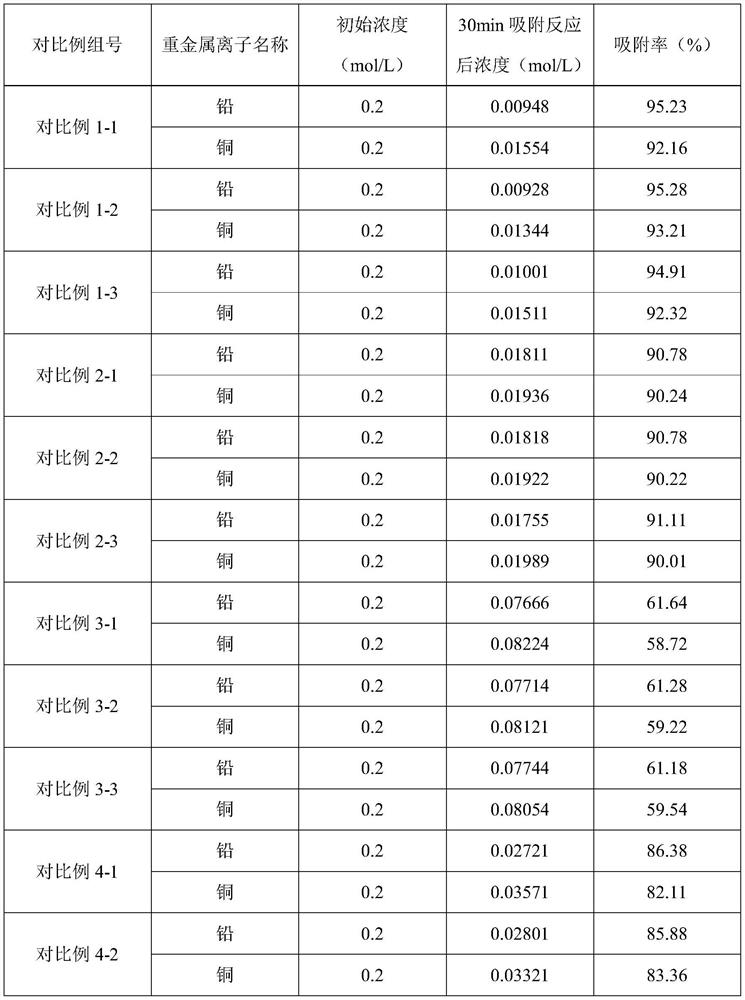

Examples

Embodiment 1

[0030] A composite heavy metal wastewater treatment porous material based on glauconite, prepared from the following raw materials in parts by weight: 24 parts of glauconite, 17 parts of deacetylated chitin, 14 parts of sodium bentonite, 8 parts of pore-forming agent, 5 parts of graphene oxide, 5 parts of sodium hydroxide;

[0031] Its preparation method, the steps are as follows:

[0032] 1) Sodium hydroxide is mixed with 8.4 times of its weight in distilled water to obtain a sodium hydroxide solution;

[0033] 2) putting glauconite, chitosan, and sodium bentonite into a crusher respectively for crushing, and then passing through a 400-mesh sieve to obtain powder;

[0034] 3) Weigh the glauconite powder, chitosan powder and sodium bentonite powder respectively, add sodium hydroxide solution, stir with a magnetic stirrer at a speed of 800r / min for 25min, and then let stand for 12h;

[0035] 4) remove the supernatant, and wash the lower sediment with water for several times; ...

Embodiment 2

[0041] A composite heavy metal wastewater treatment porous material based on glauconite, prepared from the following raw materials in parts by weight: 26 parts of glauconite, 18 parts of chitin, 15 parts of sodium bentonite, 10 parts of pore-forming agent, 5.5 parts of graphene oxide, 5 parts of sodium hydroxide;

[0042] Its preparation method is with embodiment 1.

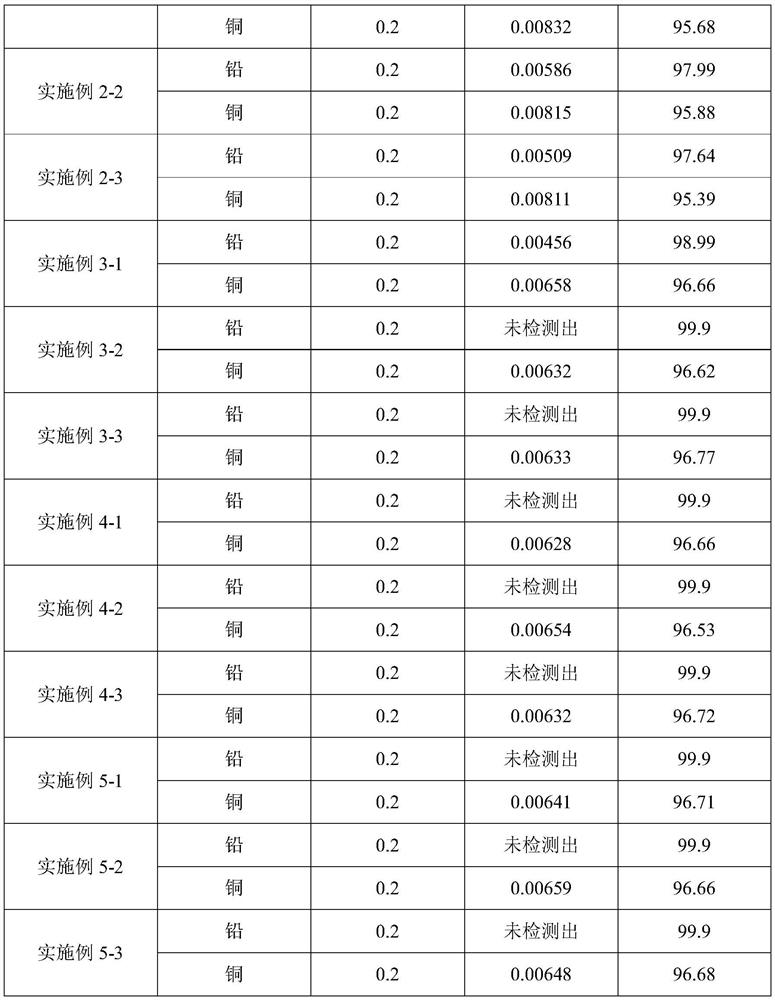

Embodiment 3

[0044] A composite heavy metal wastewater treatment porous material based on glauconite, prepared from the following raw materials in parts by weight: 28 parts of glauconite, 19 parts of chitin, 16 parts of sodium bentonite, 12 parts of pore-forming agent, 6 parts of graphene oxide, 5 parts of sodium hydroxide;

[0045] Its preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com