Suspended filtering system

A technology of suspension filtration and filter head, which is applied in the direction of filtration separation, gravity filter, loose filter material filter, etc. It can solve the problems of large water head and loss, and achieve the effect of small water head loss, saving facility investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

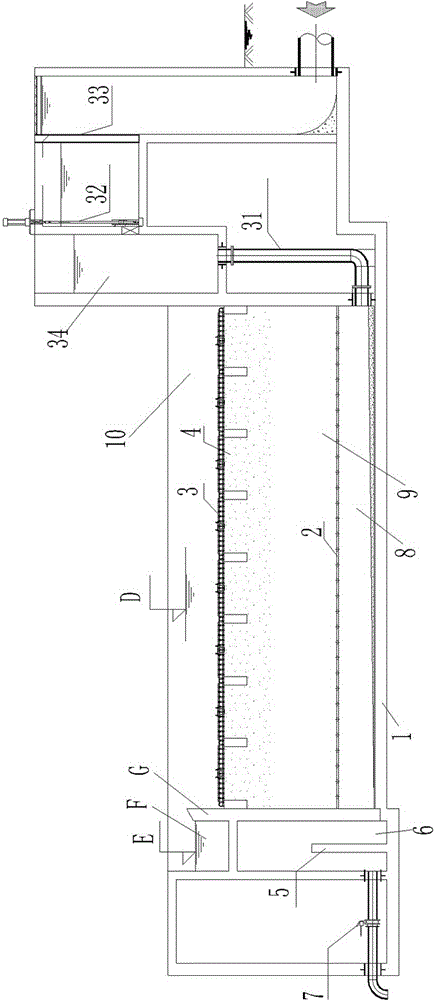

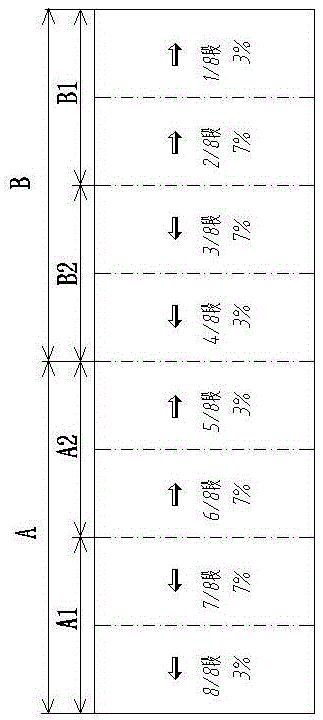

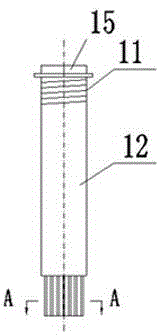

[0023] Suspension filter system of the present invention sees Figure 1-Figure 7 As shown, it includes a filter body 1 and a backwash system. The filter body is provided with an upper filter plate 3 and a water distribution channel top plate 2 at intervals up and down. The upper filter plate and the water distribution channel roof separate the space in the filter body from the upper The bottom interval is divided into three areas, which are in turn: the area above the upper filter plate 3 is the clear water storage area 10, the area below the top plate 2 of the water distribution channel is the raw water distribution channel 8, and the area between the upper filter plate and the top plate of the water distribution channel The area is a filtering area 9, wherein there is a suspended filter material 4 of predetermined thickness in the filtering area, and the density of the filter material is lower than that of water. An overflow wall G is provided between the clean water storage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com