Biofilm active sand reactor and wastewater treatment method thereof

A technology of activated sand and biofilm, applied in biological water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of large floor area, limited organic pollutant treatment capacity, and filter material compaction and other problems, to achieve the effect of high backwashing efficiency, significant removal effect, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

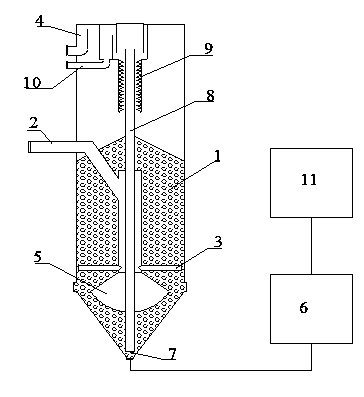

[0023] Such as figure 1 As shown, the sewage is fed into the water inlet pipe 2, and the water is evenly distributed through the water distributor 3. The sewage flows upstream from the bottom and passes through the filter material 1 in the main body. The impurities in the water are filtered, and the turbidity and chroma in the sewage are effectively removed. . Gradually increase the influent flow rate to the design flow rate. After 10 to 30 days of continuous water flow, the microorganisms in the water adhere to the filter material 1 to form a biofilm and absorb organic pollutants in the water as nutrients, and the organic pollutants in the sewage are removed. ; The purified filtrate flows out from the outlet weir 4 at the top.

[0024] When it is monitored that the turbidity of the effluent deteriorates, the air lift pump 6 is turned on for intermittent sand washing. The sand guide cone 5 guides the filter material 1 which has retained pollutants to the bottom. The air lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com