Movable drum-shaped filter screen flushing device

A flushing device and mobile technology, applied in the field of movable drum filter flushing devices, can solve the problem of people or foreign objects falling to the downstream of the drum net, affecting the downstream water level of the drum filter, effective flushing of the drum filter, etc. To reduce the risk of introducing foreign matter, reduce the risk of personnel accidents, and improve the efficiency of backwashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

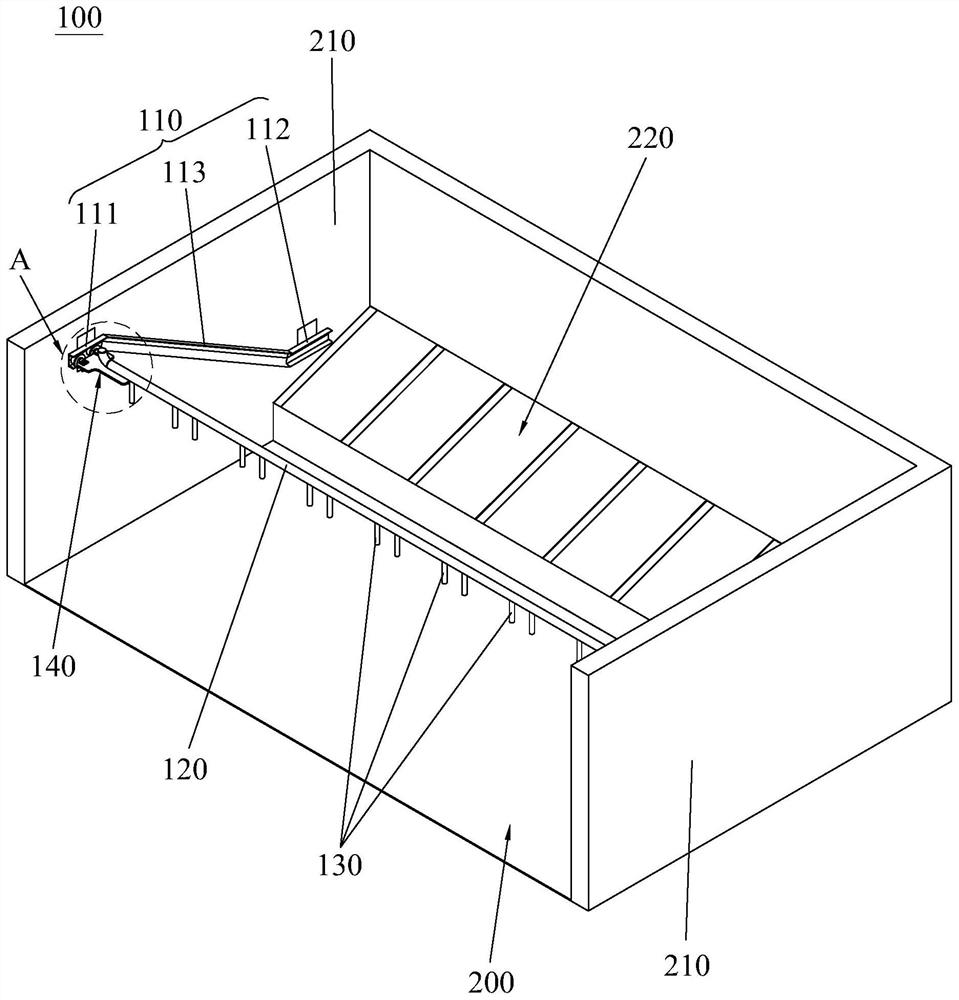

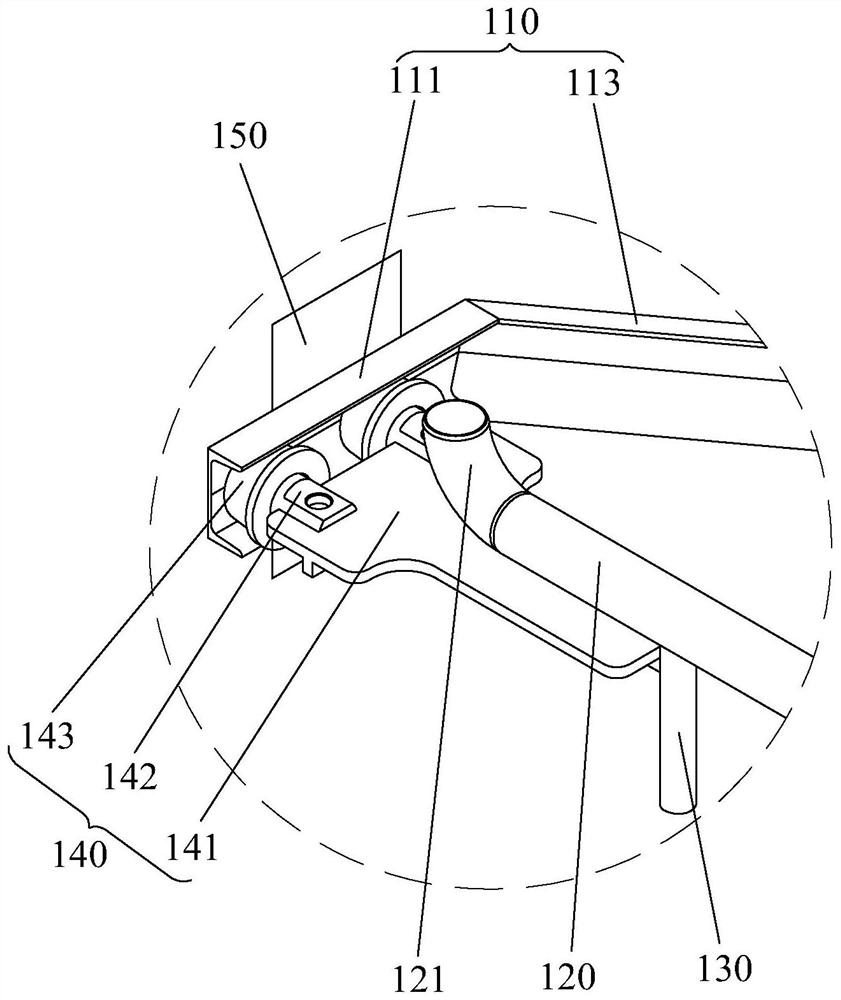

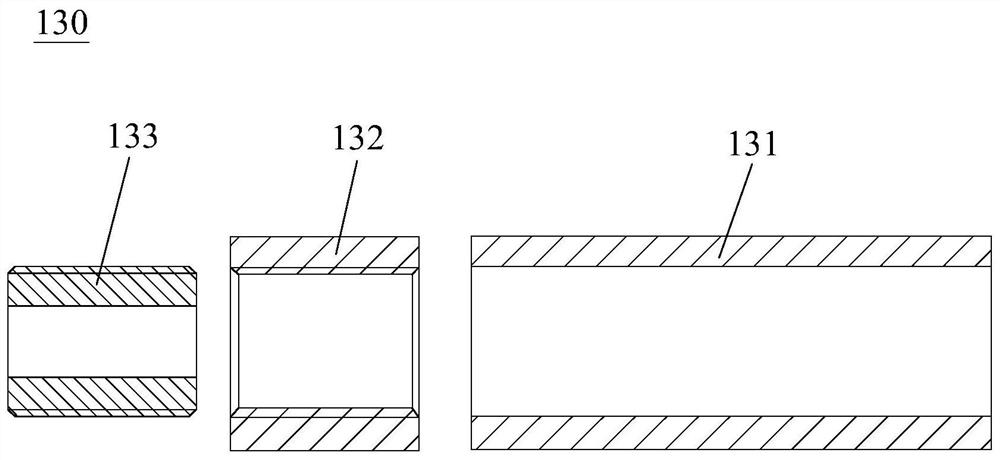

[0030] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. The movable drum-shaped filter screen flushing device 100 provided by the present invention is mainly used for flushing the outside of the drum-shaped filter screen in nuclear power plants. Of course, it is not limited to the flushing of the drum-shaped filter screen, and can also be used for other similar equipment. Clean up.

[0031] Combine first Figure 1-10 As shown, the movable drum filter rinsing device 100 provided by the present invention preferably corresponds to the installation of the drum filter. In one embodiment, it is installed on the wall 210 of the drum screen room 200, so that Rinse the drum filter. Wherein, a cover plate 220 is installed on the top of the drum-shaped filter screen to cover the drum-shaped filter screen, and the setting and installation of the drum-shaped filter screen and the cover pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com