Method for re-washing solder resist plug hole

A technology of plugging and solder masking, which is applied in the secondary processing of printed circuits, electrical components, and post-manufacturing processes, etc. It can solve the problem of easily damaged circuit board surface resin, long soaking time of plugging boards, and inability to rinse clean, etc. To avoid the whitening of the substrate or reveal the texture, improve the quality of backwashing, and improve the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

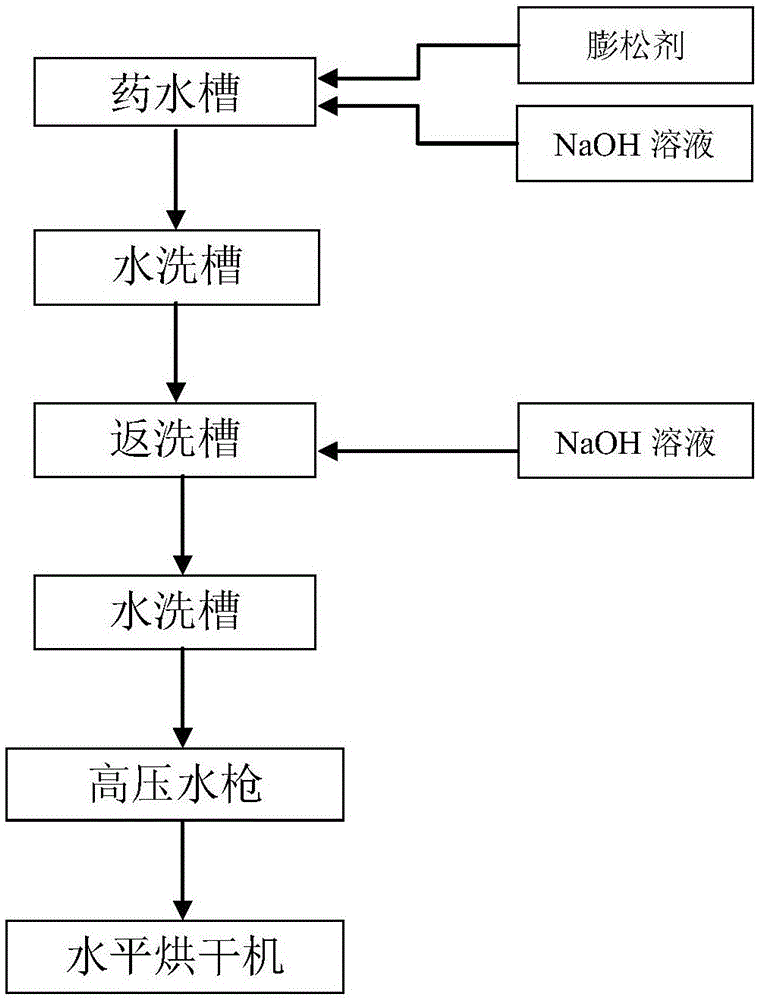

[0022] Such as figure 1 Shown is the technological process of the method for rewashing the solder resist plug hole described in the present invention, and the method comprises the following steps:

[0023] a. Soak the plug-hole plate to be backwashed in a liquid medicine tank containing a leavening agent for leavening treatment;

[0024] b. Place the plugged plate soaked in the leavening agent in a washing tank for washing to remove the leavening agent on the plate surface;

[0025] c. Soak the plug plate in a backwash tank containing NaOH solution;

[0026] d, placing the plugged orifice plate processed in step c in a water washing tank for water washing;

[0027] e. Use a high-pressure water gun to rinse the plugged hole plate after it is taken out, and remove the ink and NaOH solution on the plugged hole and the surface of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com