Method for preparing hysteresis-less lithium-thionye chloride cell

A technology of thionyl chloride battery and hysteresis lithium, which is applied in the direction of secondary batteries, circuits, electrical components, etc., and can solve problems such as good safety, voltage hysteresis, and poor battery safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

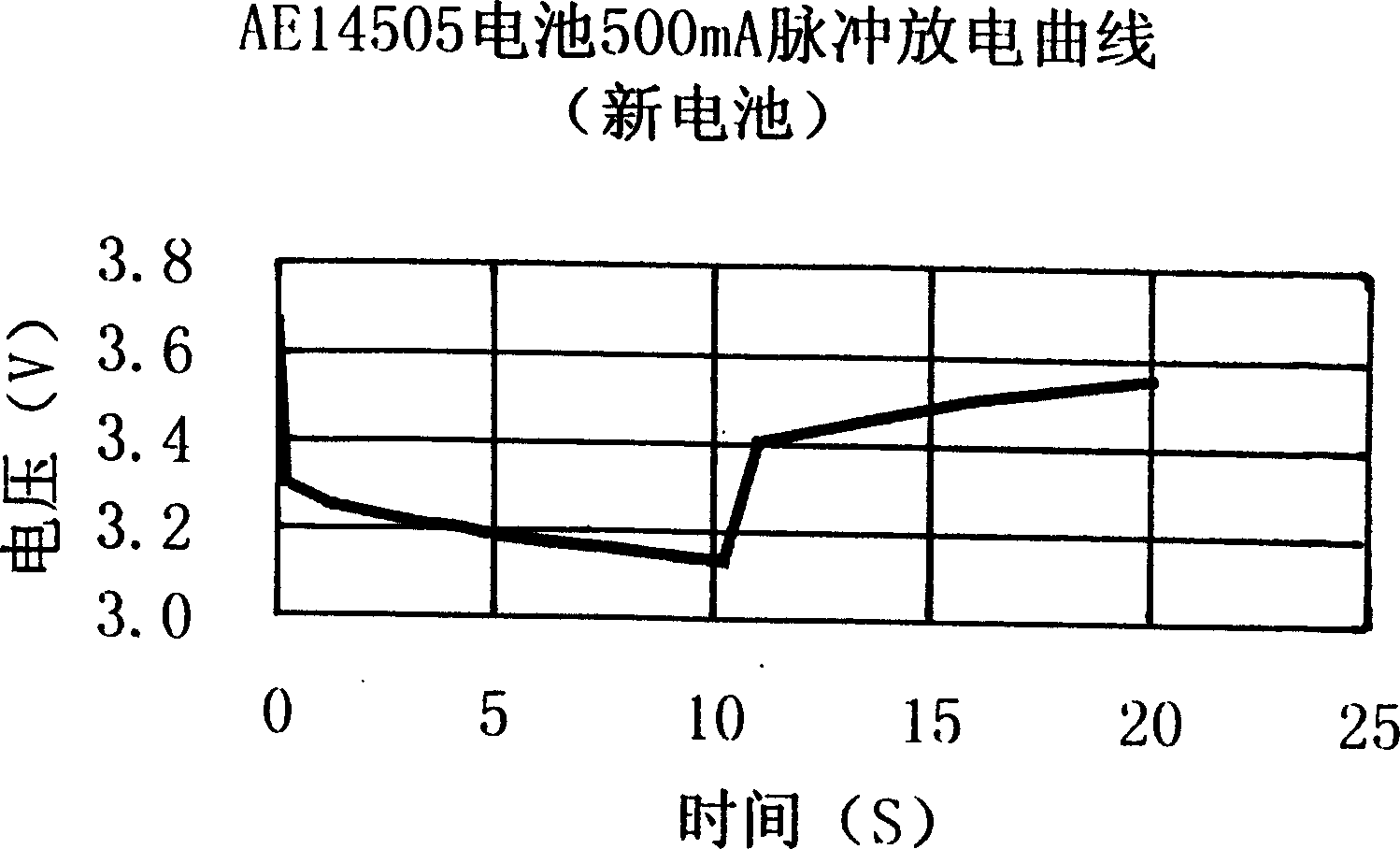

[0011] Take the AE14505 battery as an example:

[0012] Make a diameter according to accompanying drawing 1 and be that 14mm height is the traditional lithium-thionyl chloride battery of 40mm; figure 2 Shape and make a supercapacitor with the outer shell as the positive pole and the center of the bottom as the negative pole that can provide (500-1000mA) larger current pulses; The negative pole of the battery is connected together by a wire; then put the super capacitor on the battery and align it with the battery, and the connection part is filled with resin glue to fix the two parts. At this time, it becomes a whole, and the positive pole of the super capacitor is used as the positive pole of the new battery. The bottom of the battery case of the battery serves as the negative electrode.

[0013] Its working principle is as follows: a traditional lithium battery is connected in parallel with a supercapacitor. The battery charges the supercapacitor at ordinary times. The sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com