Tubular oil and water separation device

An oil-water separation device, a tubular technology, applied in separation methods, liquid separation, grease/oily substance/floating matter removal devices, etc., can solve the problems of high requirements for processing materials, large equipment volume, and high equipment cost, and achieve equipment manufacturing. Low requirements, high separation effect, low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

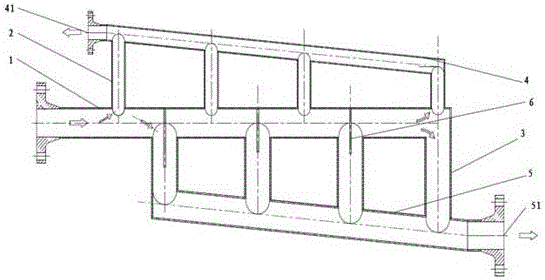

[0017] Such as figure 1 A tubular oil-water separation device shown includes a connecting pipe 1, an oil phase flotation tube group 2, a water phase settling tube group 3, an oil collecting tube 4 and a water collecting tube 5; the oil phase flotation tube group 2 and the water phase settling The axes of the tube groups 3 are parallel to each other, and the oil phase flotation tube groups 2 and the water phase settling tube groups 3 are arranged alternately on the connecting pipe 1 .

[0018] One end of the connecting pipe 1 is closed, one end is open, and the opening end is provided with a flange; the side wall of the connecting pipe 1 along the axial direction is respectively provided with an oil phase flotation tube hole group and a water phase settling tube hole group; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com