Automatic mold selecting system and control method thereof

A control method and mold technology, applied in the field of composite material processing, can solve the problems of long time consumption, damage to molds, waste of human resources, etc., and achieve the effects of reducing time, improving moving efficiency, and shortening moving paths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

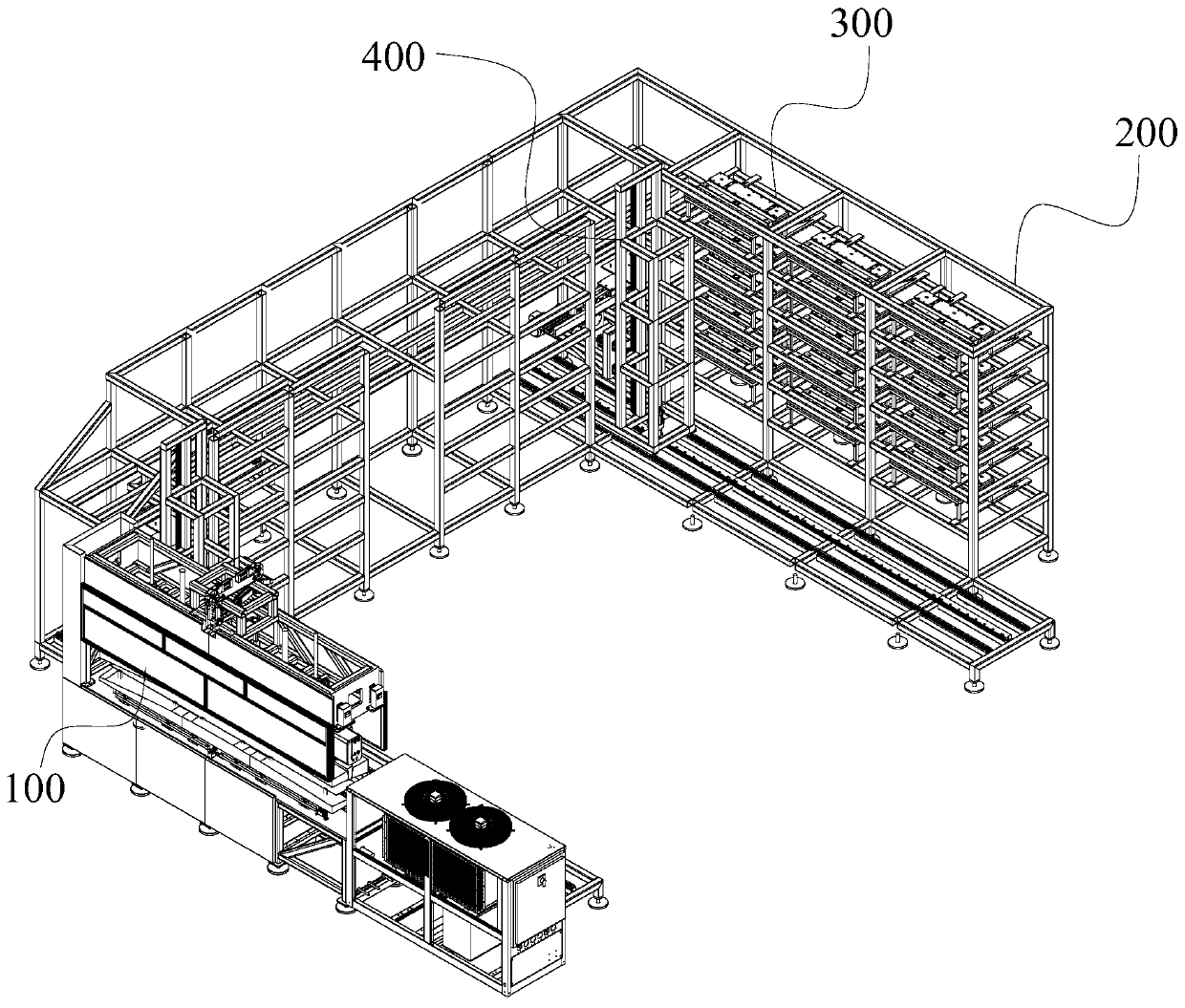

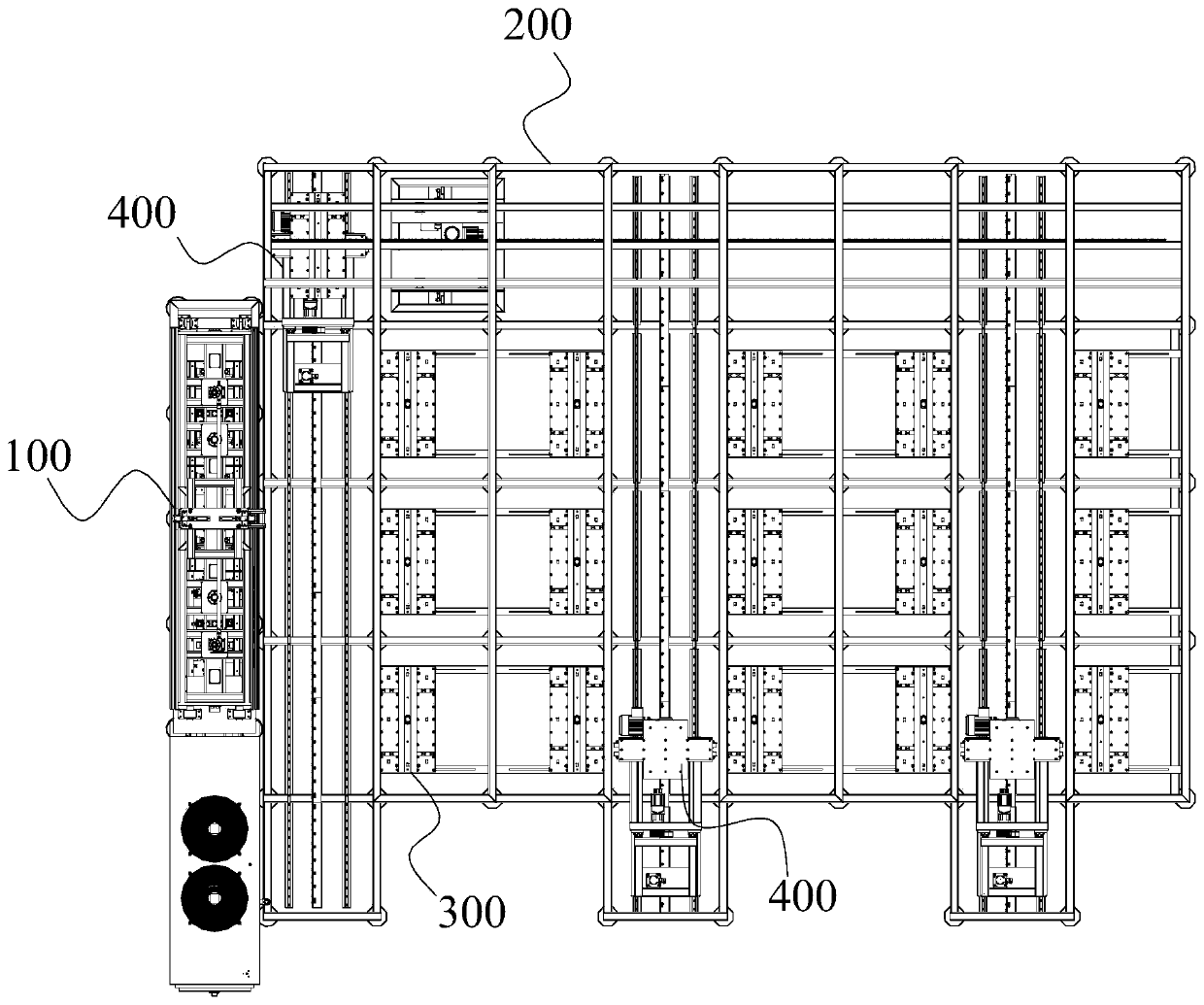

[0043] Such as Figure 1 to Figure 10 The automatic mold selection system shown includes:

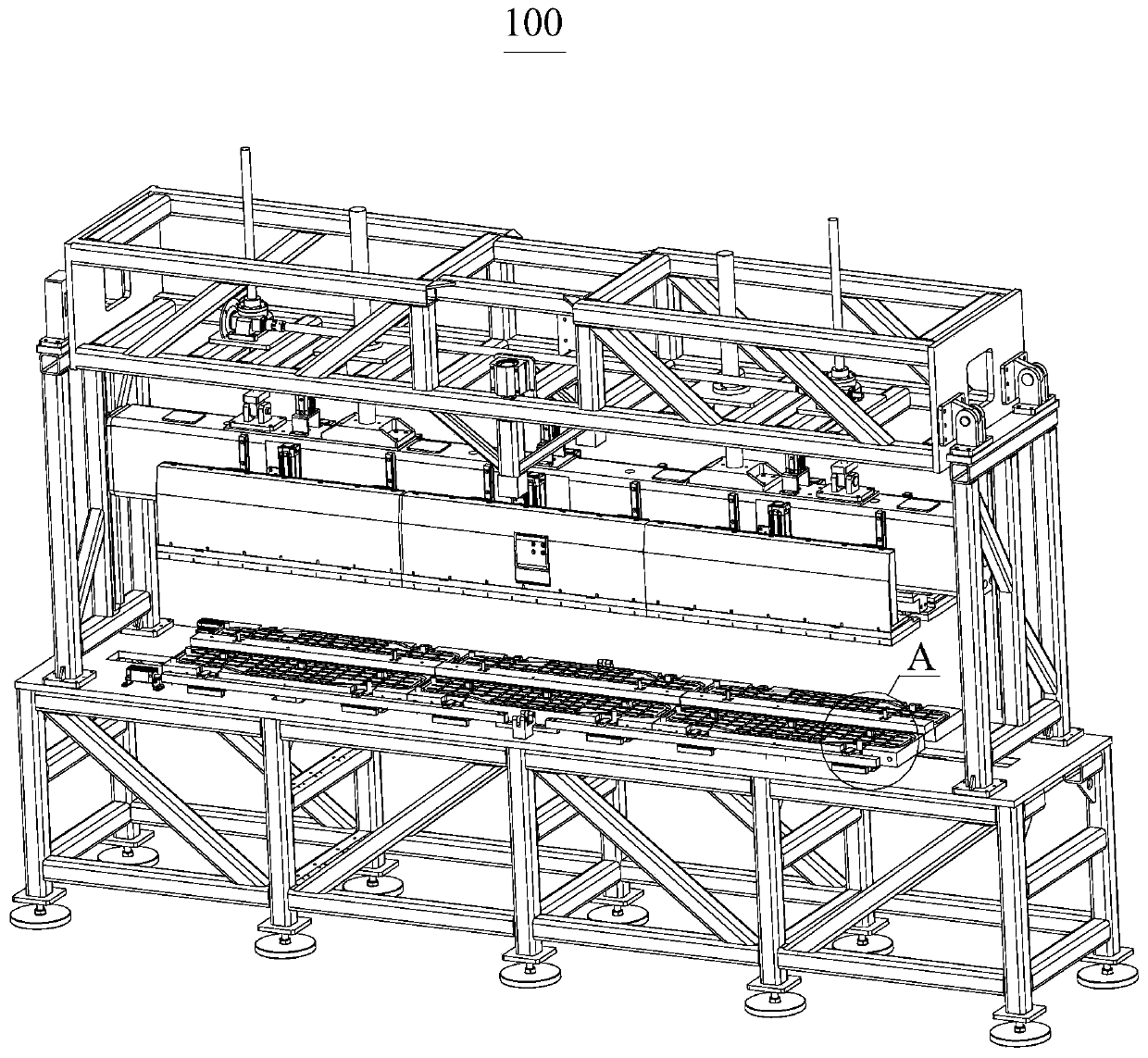

[0044] Preforming device 100, the length direction is the same as the length direction of the stringer to be processed; as image 3 As shown, the preforming device 100 is used for forming long stringers, and the upper mold is driven up and down by the turbine screw elevator on the frame, so as to form the laminate placed on the lower mold.

[0045] The support 200 is arranged in parallel with the preforming device 100; as figure 2 As shown, the function of the support 200 is on the one hand as a mold storehouse for storing molds, and on the other hand it is also used to sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com