Vision inspection apparatus

A visual detection device and visual detection technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of increasing the size of the visual detection device, easily disturbing the work of the operator, and high cost of the visual detection device. Effects of re-inspection, reduction of transmission time, and reduction of operation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

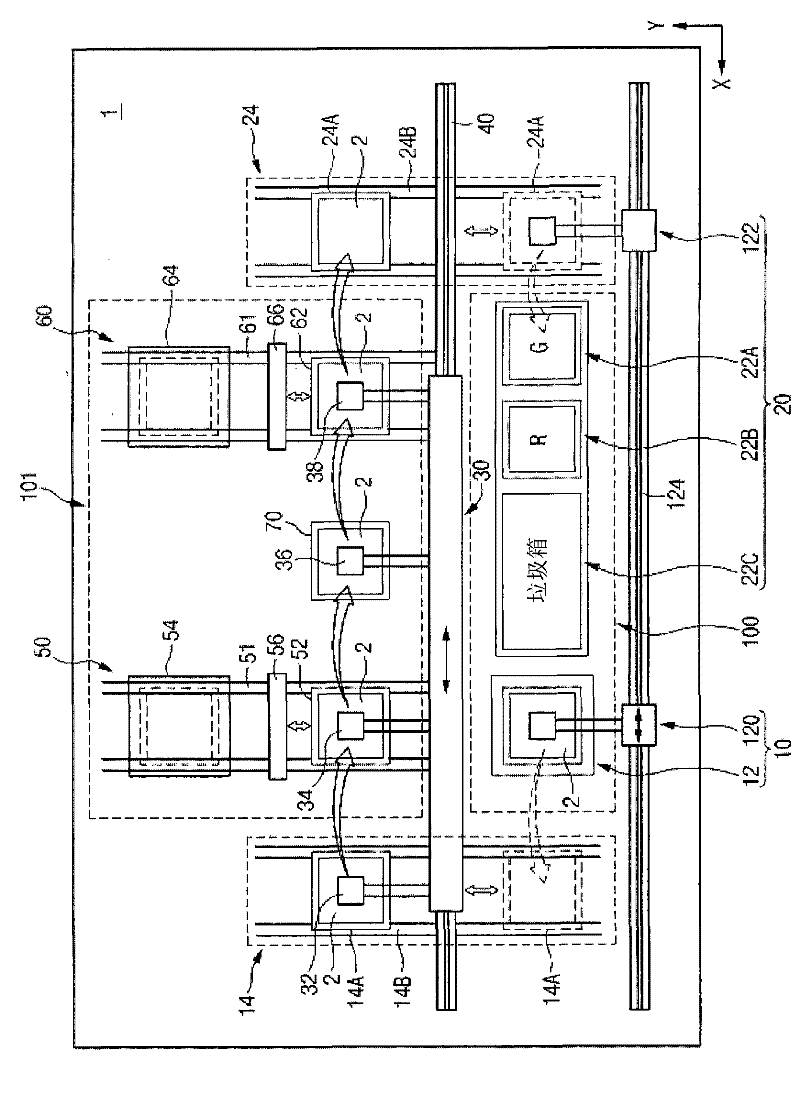

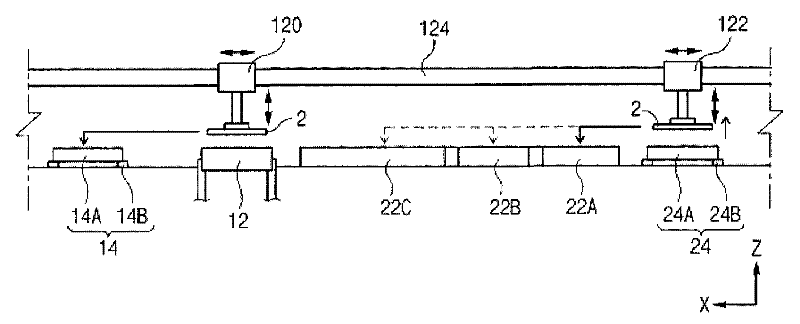

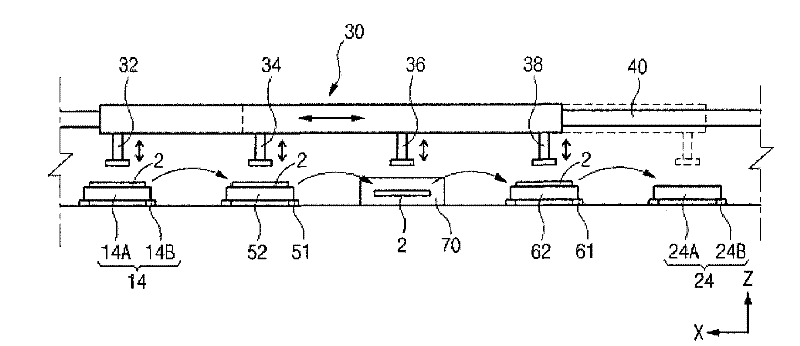

[0054] The present invention will now be described in detail with reference to the accompanying drawings.

[0055] The visual detection device according to the present invention will be described in more detail below with reference to the accompanying drawings.

[0056] The visual inspection device 1 according to the present invention is used for sorting the electronic components 2 by inspecting the appearance of the electronic components 2 . Here, the electronic component 2 may be a semiconductor device, a semiconductor strip, a semiconductor component, etc., and its appearance may affect the reliability of the product.

[0057] The visual detection device 1 may include a loading unit 10 for loading at least one electronic component to be visually detected, a first visual detection unit 50 for implementing a first visual detection of the electronic component 2, and a second visual detection unit 50 for implementing a second visual detection of the electronic component 2. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com