Adding device of paper pulp moulding assistant

A technology of adding device and pulp molding, which is applied in the process of adding pulp raw materials, papermaking, textiles and papermaking, etc. It can solve the problem of affecting the output quality and production efficiency of pulp molding products, and the uneven mixing of additives and grouting pipeline slurry , weakening the retention effect and other issues, to prevent long-term dispersion failure, improve the efficiency and uniformity of addition, and improve the quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

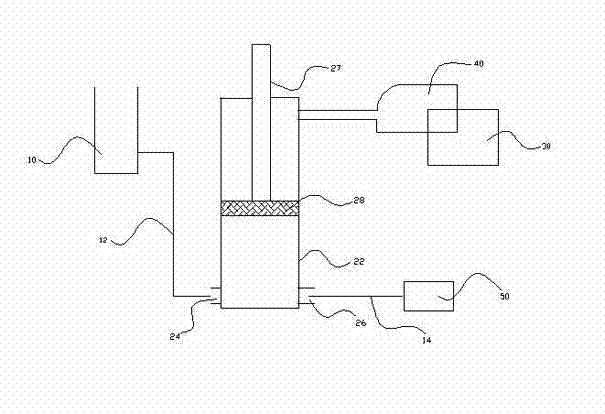

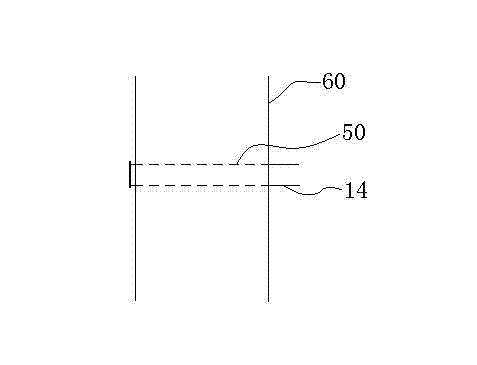

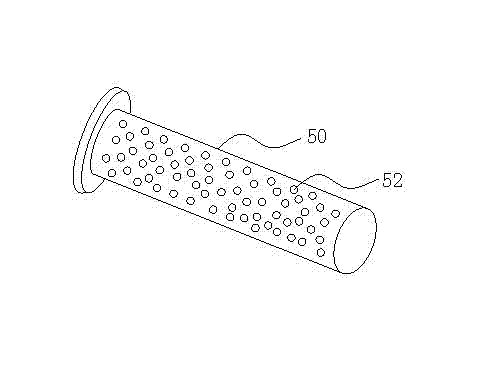

[0031] as attached figure 1 , 2, 3, 5 and 6, an embodiment of the pulp molding additive adding device of the present invention is mainly composed of an additive storage tank 10, an additive delivery pipeline 12 and 14, a cylinder 22, a movable limit adjustment piston 28, Pneumatic unit 40, liquid inlet and outlet one-way valves 24 and 26 and control system 30 are composed. The storage capacity of the auxiliary agent storage tank 10 is 50 L. The storage tank 10 is connected and sealed with the auxiliary agent input pipeline 12 through a one-way valve 24 . The movable limit adjustment piston 28 relatively moves in the cylinder 22 under the control of the pneumatic element 40 to realize the suction and discharge of the auxiliary agent. The discharged auxiliary agent passes through the one-way valve 26 and is connected to the auxiliary agent dispersion pipe 50 through the output pipe 14 . The pneumatic unit 40 is the direct power supply and control component of the piston move...

Embodiment 2

[0033] as attached figure 1 , 2 , 3, 5 and 6, an embodiment of the pulp molding additive adding device of the present invention is mainly composed of an additive storage tank 10, an additive delivery pipeline 12 and 14, a cylinder 22, a movable limit adjustment piston 28, Pneumatic unit 40, liquid inlet and outlet one-way valves 24 and 26 and control system 30 are composed. The storage capacity of the auxiliary agent storage tank 10 is 200 L. The storage tank 10 is connected and sealed with the auxiliary agent input pipeline 12 through a one-way valve 24 . The movable limit adjustment piston 28 relatively moves in the cylinder 22 under the control of the pneumatic element 40 to realize the suction and discharge of the auxiliary agent. The discharged auxiliary agent passes through the one-way valve 26 and is connected to the auxiliary agent dispersion pipe 50 through the output pipe 14 . The pneumatic unit 40 is the direct power supply and control component of the piston mo...

Embodiment 3

[0035] as attached figure 1 , 2 , 4, 5 and 6, an embodiment of the pulp molding additive adding device of the present invention is mainly composed of an additive storage tank 10, an additive delivery pipeline 12 and 14, a cylinder 22, a movable limit adjustment piston 28, Pneumatic unit 40, liquid inlet and outlet one-way valves 24 and 26 and control system 30 are composed. The storage capacity of the auxiliary agent storage tank 10 is 400 L. The storage tank 10 is connected and sealed with the auxiliary agent input pipeline 12 through a one-way valve 24 . The movable limit adjustment piston 28 relatively moves in the cylinder 22 under the control of the pneumatic element 40 to realize the suction and discharge of the auxiliary agent. The discharged auxiliary agent passes through the one-way valve 26 and is connected to the auxiliary agent dispersion pipe 50 through the output pipe 14 . The pneumatic unit 40 is the direct power supply and control component of the piston mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com