New energy automobile motor copper wire automatic molding equipment

A new energy vehicle and copper wire technology, applied in the field of copper wire forming, can solve the problems of poor overall effect and inability to realize automatic production of copper wire, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

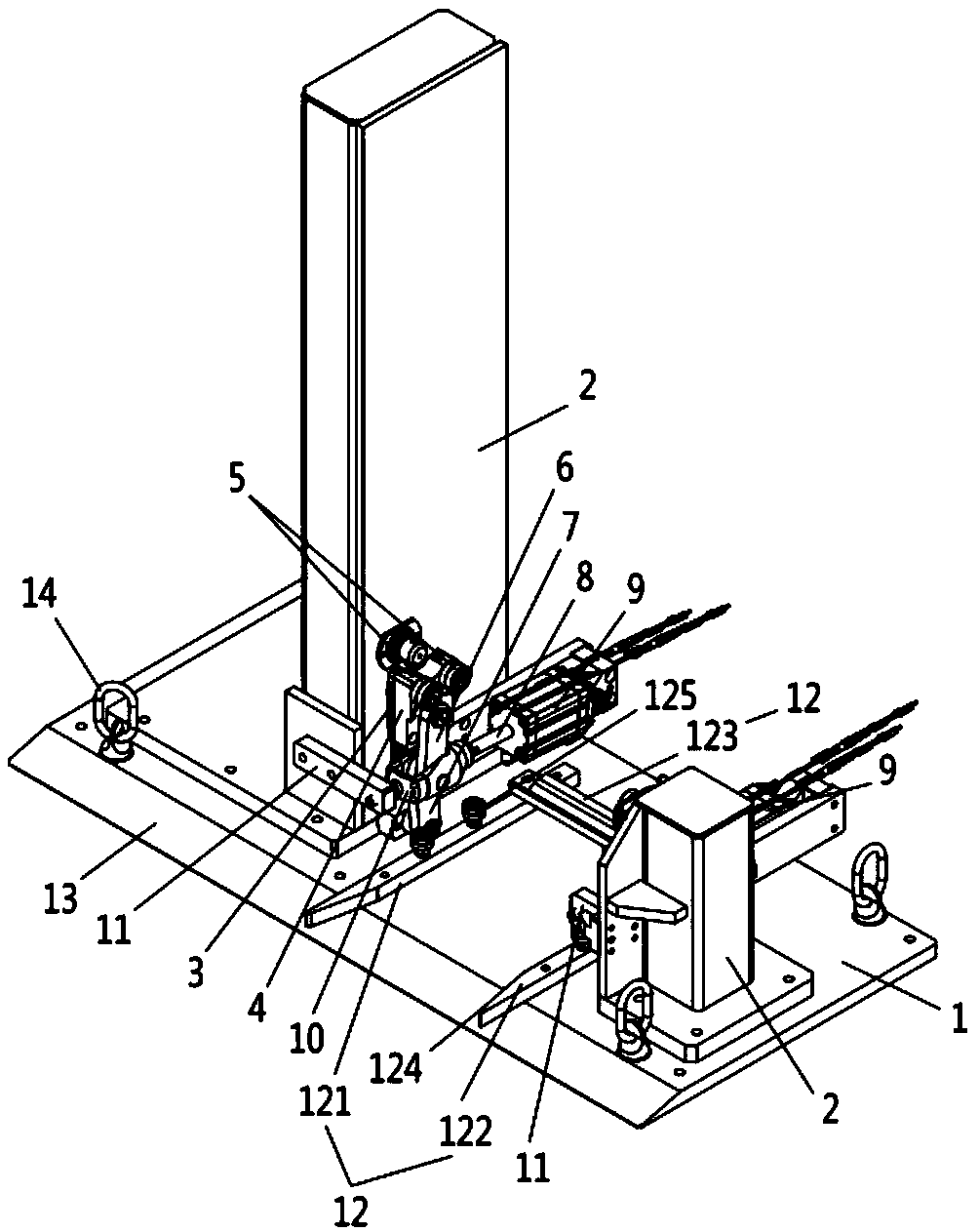

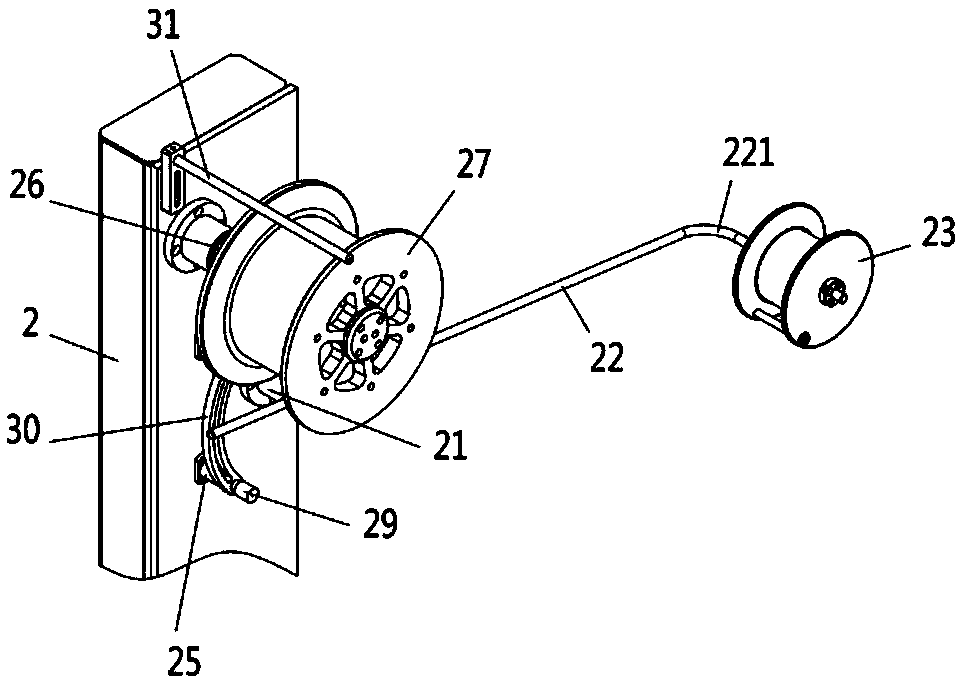

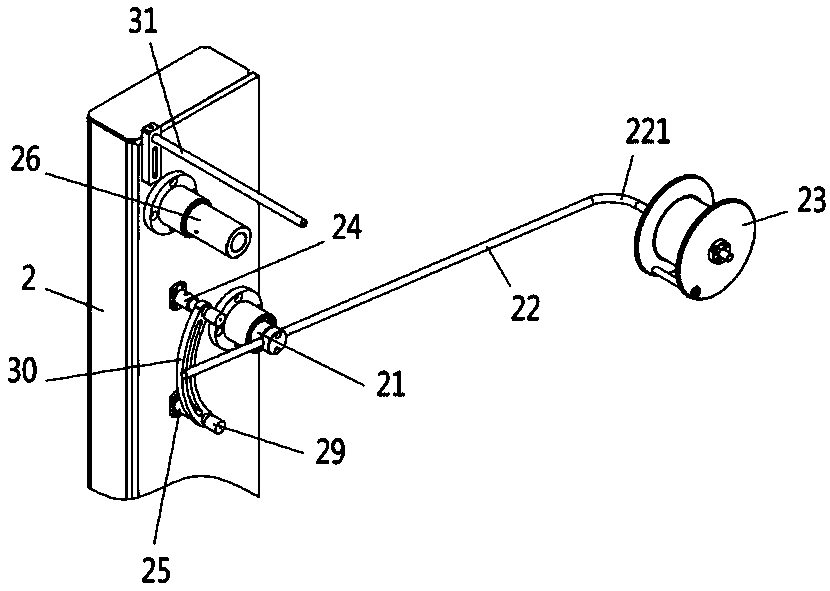

[0061] see Figures 1 to 48 As shown, the automatic forming integrated equipment for a copper wire for a new energy automobile motor involved in this embodiment includes an assembly slide rail 406, one end of the assembly slide rail 406 is provided with a copper wire coil unwinding device 10000, and the other end is provided with There is a copper wire forming device 60000, between the copper wire reel unwinding device 10000 and the copper wire forming device 60000, a copper wire paint stripping device 20000, a copper wire pulling device 30000, and a copper wire cutting device 40000 are arranged sequentially from left to right and copper wire automatic clamping device 50000, the bottom of the copper wire paint stripping device 20000 is provided with an assembly slider 401, and the assembly slider 1 401 is slidably connected to the assembly sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com