Eccentric planetary polishing device of large-caliber aspheric robot

A polishing device and aspheric surface technology, which is applied in the direction of grinding drive device, grinding/polishing equipment, optical surface grinder, etc., can solve the problems of low efficiency, backward production technology, waste of human and material resources, etc., to improve processing efficiency, Reduced size and weight for precise control of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

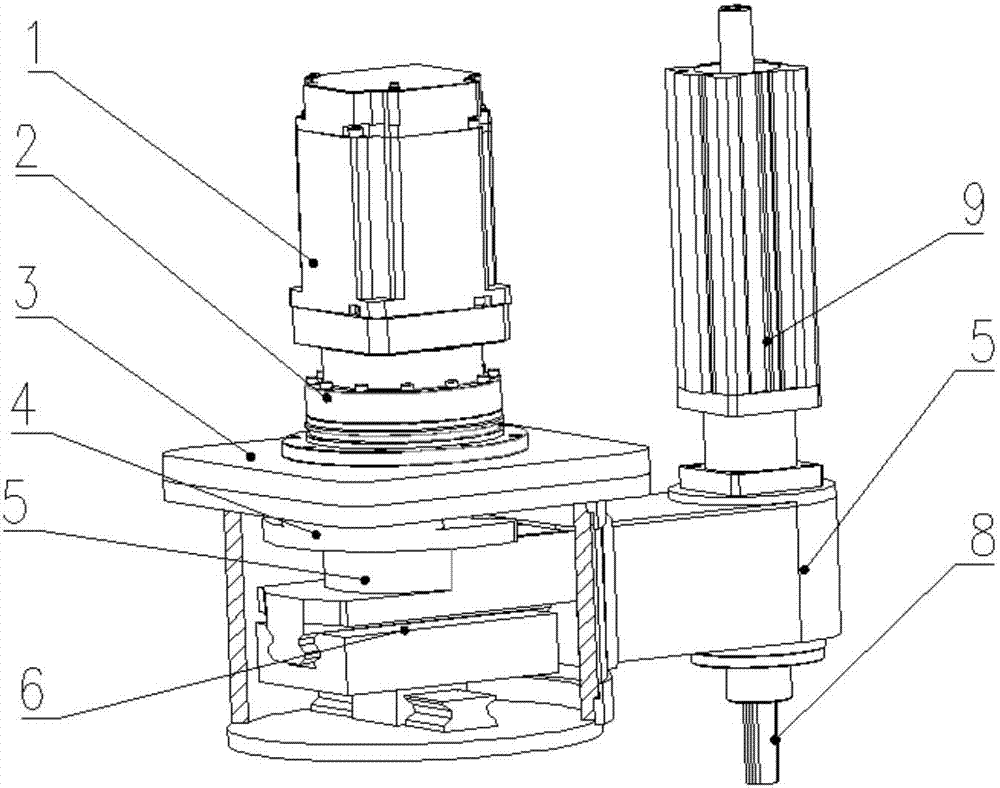

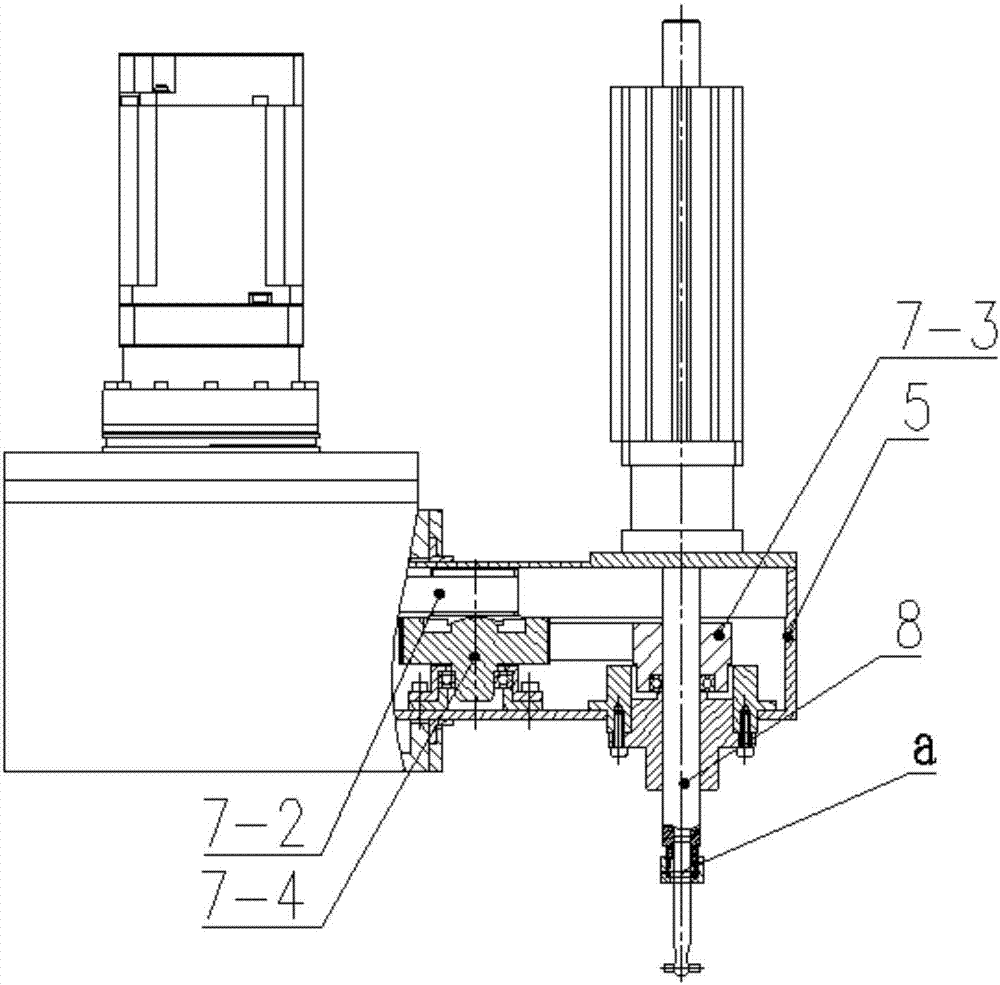

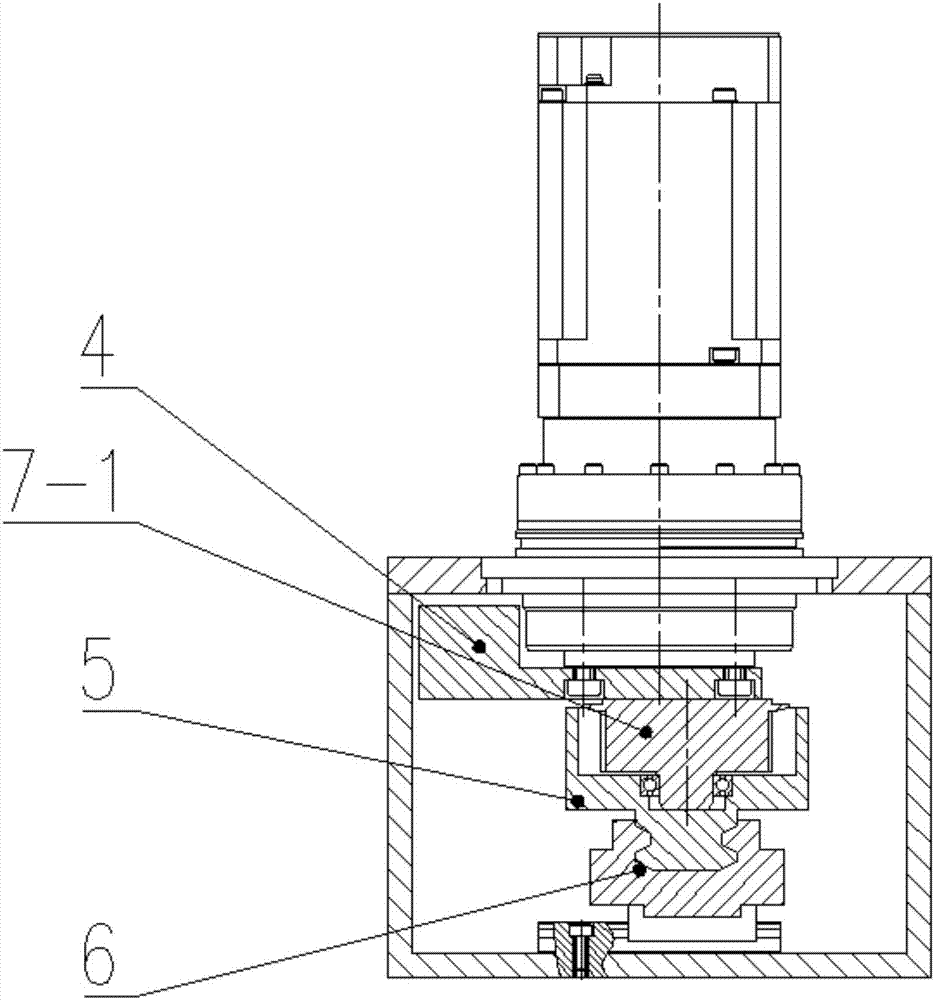

[0011] Referring to the accompanying drawings, the large-diameter aspheric robot eccentric planetary polishing device of the present invention includes a servo motor 1 and a low-friction cylinder 9 arranged in parallel with the servo motor 1, the output shaft of the servo motor 1 and the cylinder The piston rods are all arranged vertically, and the low-friction cylinder is fixed on the top plate on the right side of the fixed housing 5 of the transmission mechanism. The piston rod of the low-friction cylinder passes through a transition joint and a rotary joint and shaft connection, the spline shaft 8 is used as a polishing shaft. The spline shaft and the spline nut are slidingly connected, the spline nut is fixed on the fixed housing 5 of the transmission mechanism, the transition joint is fixedly connected to the lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com