Preparation of environment-friendly metal polishing solution

A kind of polishing liquid, an environment-friendly technology, applied in the field of preparation of environment-friendly metal polishing liquid, can solve problems such as insufficient, and achieve the effect of low price, low corrosion and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

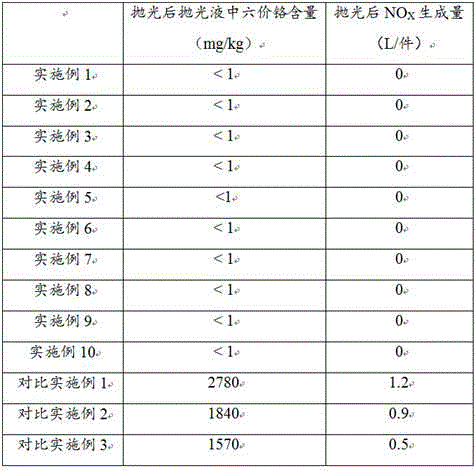

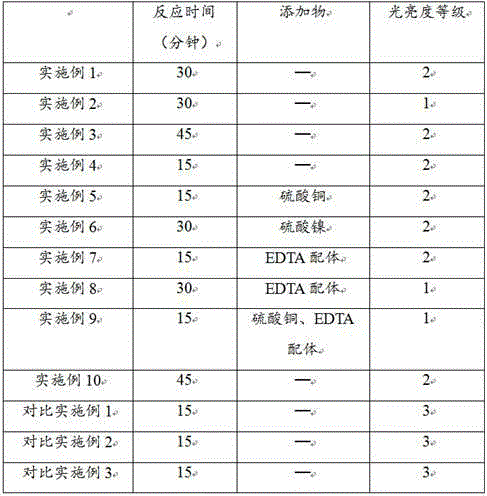

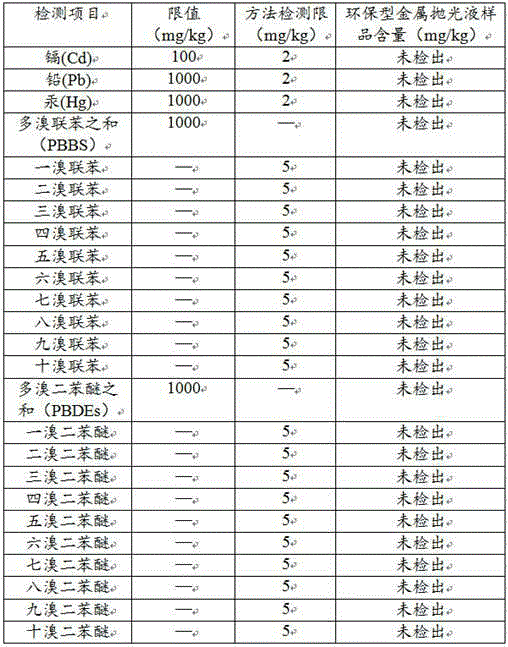

Examples

Embodiment 1

[0029] Metal polishing liquid preparation method: mix 8kg acetic acid and 7kg diethylamine, then add 2kg lauryl polyoxyethylene ether, 1kg PEG-600, 3kg sodium silicate and distilled water, and then stir at room temperature for 30 minutes to obtain Required metal polishing fluid. The final concentration of each component of the prepared environment-friendly metal polishing liquid is as follows: polyoxyethylene lauryl ether 2wt%, acetic acid 8wt%, diethylamine 7wt%, PEG-600 1wt%, sodium silicate 3wt% and water.

[0030] Polishing method: Add 350kg of zirconium beads, 200mL of the above metal polishing solution and an appropriate amount of water into a 300L vibration machine, then add the stainless steel workpiece to be polished, vibrate for 15 minutes at room temperature, and then take out the workpiece.

Embodiment 2

[0032] Metal polishing liquid preparation method: mix 12kg dodecylbenzenesulfonic acid and 6kg triethanolamine, then add 3kg alkylbenzenesulfonate sodium, 0.6kg benzaldehyde, 2kg sodium borate and distilled water to it, and then under room temperature Stir for 30 minutes to obtain the desired metal polishing solution. The final concentration of each component of the prepared environment-friendly metal polishing liquid is as follows: sodium alkylbenzenesulfonate 3wt%, dodecylbenzenesulfonic acid 12wt%, triethanolamine 6wt%, benzaldehyde 0.6wt%, sodium borate 2wt%.

[0033] Polishing method: Add 450kg of stainless steel beads, 300mL of the above metal polishing solution and an appropriate amount of water into a 300L vibration machine, then add the stainless steel workpiece to be polished, vibrate for 30 minutes at room temperature, and then take out the workpiece.

Embodiment 3

[0035] Metal polishing liquid preparation method: mix 12kg ethylsulfonic acid and 6kg triethylamine, then add 3kg sodium alkylbenzenesulfonate, 0.6kg benzaldehyde, 2kg sodium borate and distilled water, then stir at room temperature for 30 Minutes to get the desired metal polishing solution. The final concentration of each component of the prepared environment-friendly metal polishing liquid is as follows: sodium alkylbenzenesulfonate 3wt%, ethylsulfonic acid 12wt%, triethylamine 6wt%, benzaldehyde 0.6wt%, sodium borate 2wt%.

[0036] Polishing method: Add 550kg of stainless steel beads, 300mL of the above metal polishing solution and an appropriate amount of water into a 300L vibrating machine, then add the stainless steel workpiece to be polished, vibrate for 30 minutes at room temperature, and then take out the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com