Chemical polishing agent for stainless steel product surface polishing, preparation method and polishing method thereof

A technology of chemical polishing and surface polishing, which is applied in the field of mixed solutions for polishing the surface of stainless steel products. It can solve the problems of large number of workers, poor polishing effect, complex appearance of stainless steel products, etc., and achieves low polishing cost and reduced price difference. Problems, the effect of reducing the requirements of wastewater treatment conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] This embodiment describes the present invention in detail by preparing 1 liter of polishing agent.

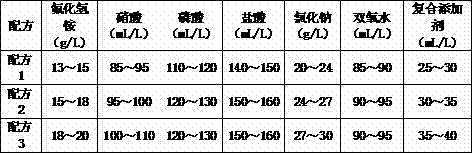

[0032] A chemical polishing agent used for surface polishing of stainless steel products. The proportion of main components per liter of solution is as follows: Ammonium bifluoride (NH4HF2) 13g / L-20g / L, nitric acid (HNO3) 85mL / L-110mL / L, phosphoric acid ( H3PO4) 110mL / L~130mL / L, hydrochloric acid (HCl) 140mL / L~160mL / L, sodium chloride (NaCl) 20g / L~30g / L, hydrogen peroxide (H2O2) 85mL / L~95mL / L, composite additive 25mL / L~40mL / L, prepared by adding appropriate amount of water;

[0033] The main components per liter of solution of the composite additive are as follows: hexamethylenetetramine 4g / L~6g / L, polyethylene glycol 10g / L~15g / L, urea 10g / L~12g / L , Sulfosalicylic acid 5g / L ~ 7g / L, OP emulsifier 4g / L ~ 8g / L, add appropriate amount of water to prepare.

[0034] The purity grade of each component in the above-mentioned composite additive is AP grade or above grade.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com