Polishing device and polishing method of 3D glass board

A polishing device and glass plate technology, applied in grinding/polishing equipment, machine tools for surface polishing, abrasives, etc., can solve the problems of low yield, high cost, and high price of 3D glass plate products, and achieve curved surface profile. Accurate radian, good repeat positioning accuracy, convenient and quick debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

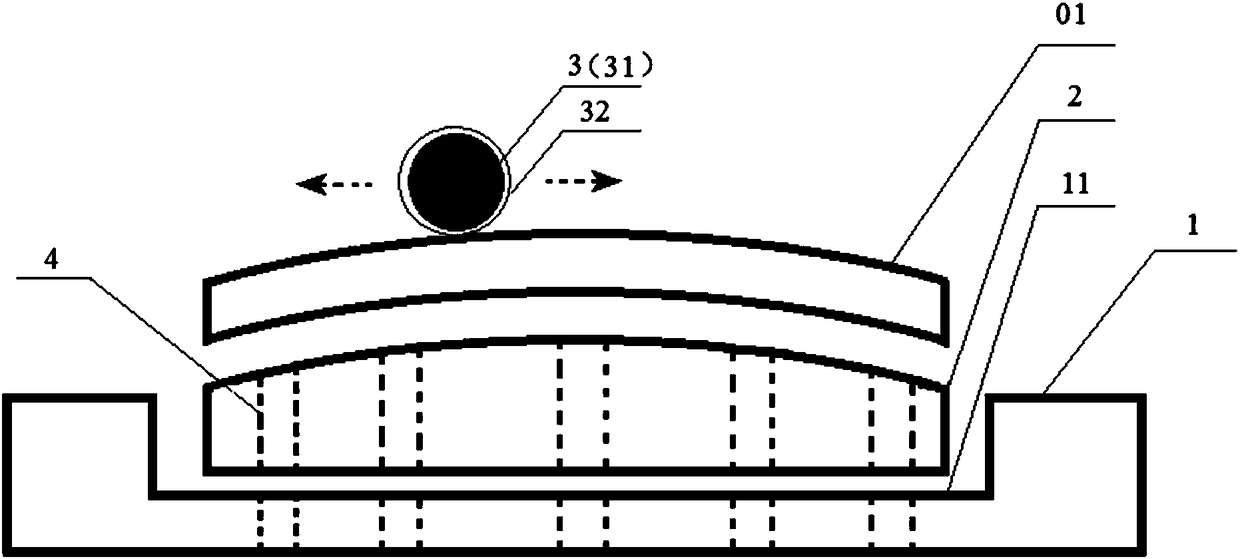

[0017] The invention provides a polishing device for a 3D glass plate. The 3D glass plate is a glass plate whose two ends in the length direction of the plate surface are bent toward the same direction. The polishing device includes a polymer base plate 1 (fiber plate), a curved rubber The plate 2 and the polishing rod 3 also include a vacuum suction channel 4 which is arranged on the polymer bottom plate 1 and the curved rubber plate 2 and is used for fixing the 3D glass plate during polishing. Plate 2 and cavity 11 positioned for the 3D glass plate, the curved rubber plate 2 includes a curved top surface and is used to support the 3D glass plate 01, the polishing rod includes a cylindrical steel core 31 and is fixedly arranged outside it The soft grinding skin 32 on the circular surface, the polishing rod 3 is arranged above the 3D glass plate 01 and the polishing rod is driven by external force to rotate so that the soft grinding skin of the polishing rod is in contact with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com