Chemical mechanical polishing liquid

A chemical mechanical and polishing liquid technology, which is applied in the direction of polishing compositions containing abrasives, etc., can solve problems such as sedimentation, low concentration of tungsten polishing liquid, loss of polishing performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] All the raw materials used in this example are commercially available, and all components are dissolved and mixed evenly, and the mass percentage is made up to 100% with water. Adjust to the desired pH value with a pH regulator to obtain specific examples as follows.

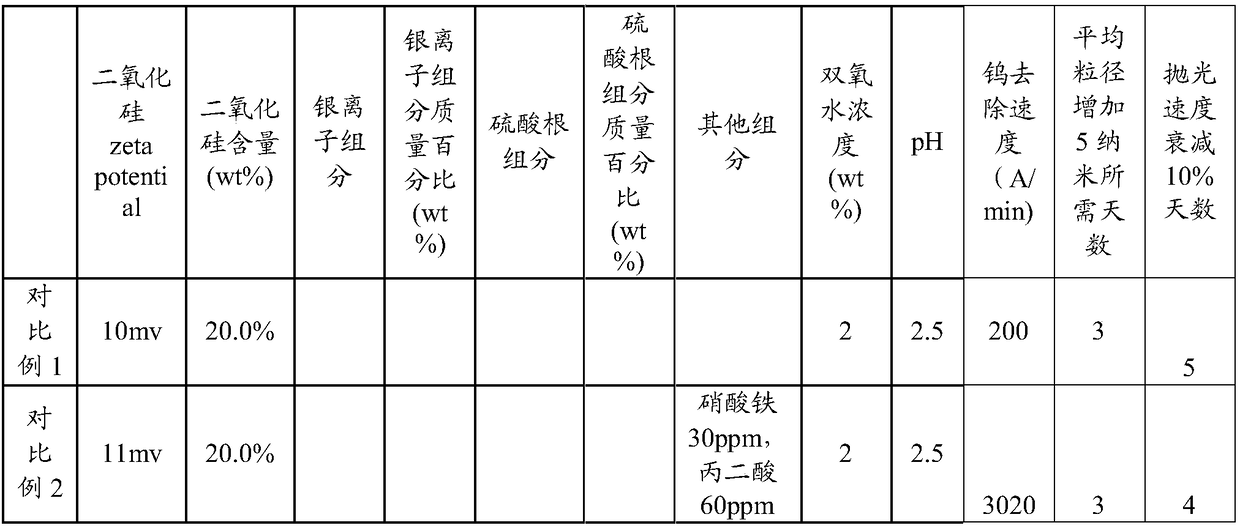

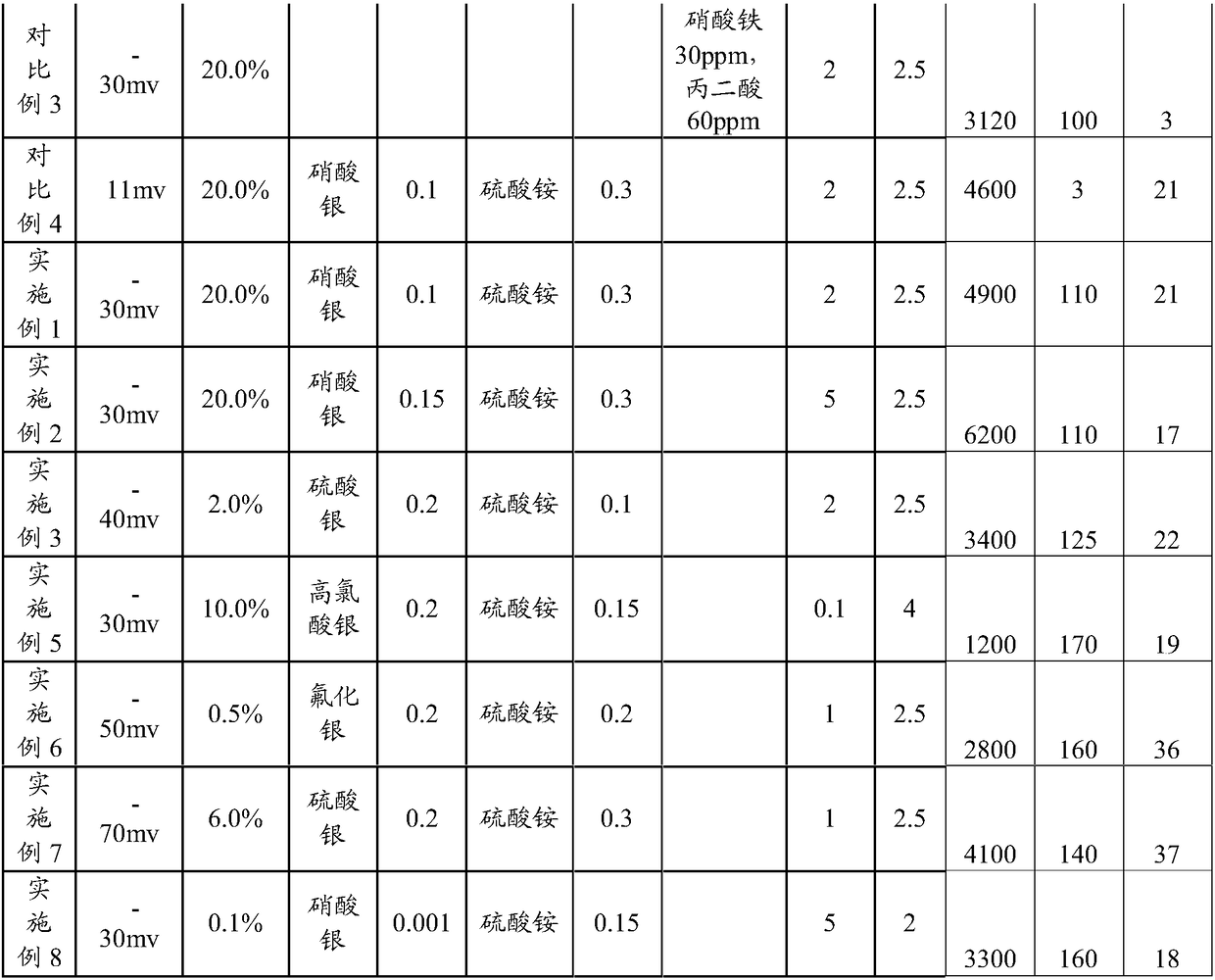

[0026] Table 1 comparative ratio and embodiment proportioning and concrete implementation result

[0027]

[0028]

[0029] The polishing solutions prepared in the above-mentioned Examples 1-8 and Comparative Example were respectively subjected to chemical mechanical polishing of tungsten, and the polishing effects were compared.

[0030] Polishing conditions: the polishing machine is Mirra, IC1010 polishing pad, the grinding pressure is 3psi, and the polishing droplet velocity is 100ml / min.

[0031] Table 1 is the proportioning and specific implementation results of comparative examples and embodiments. Wherein, comparative example 1 shows that when only abrasive and hydrogen peroxide exist, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com