Wide/fine machining integrated processing device for emery belt centerless grinding and polishing

A processing device and centerless grinding technology, which is applied in the direction of abrasive belt grinders, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of complex operation, inconvenient installation, and many equipment, and achieve simple operation and high grinding efficiency , high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

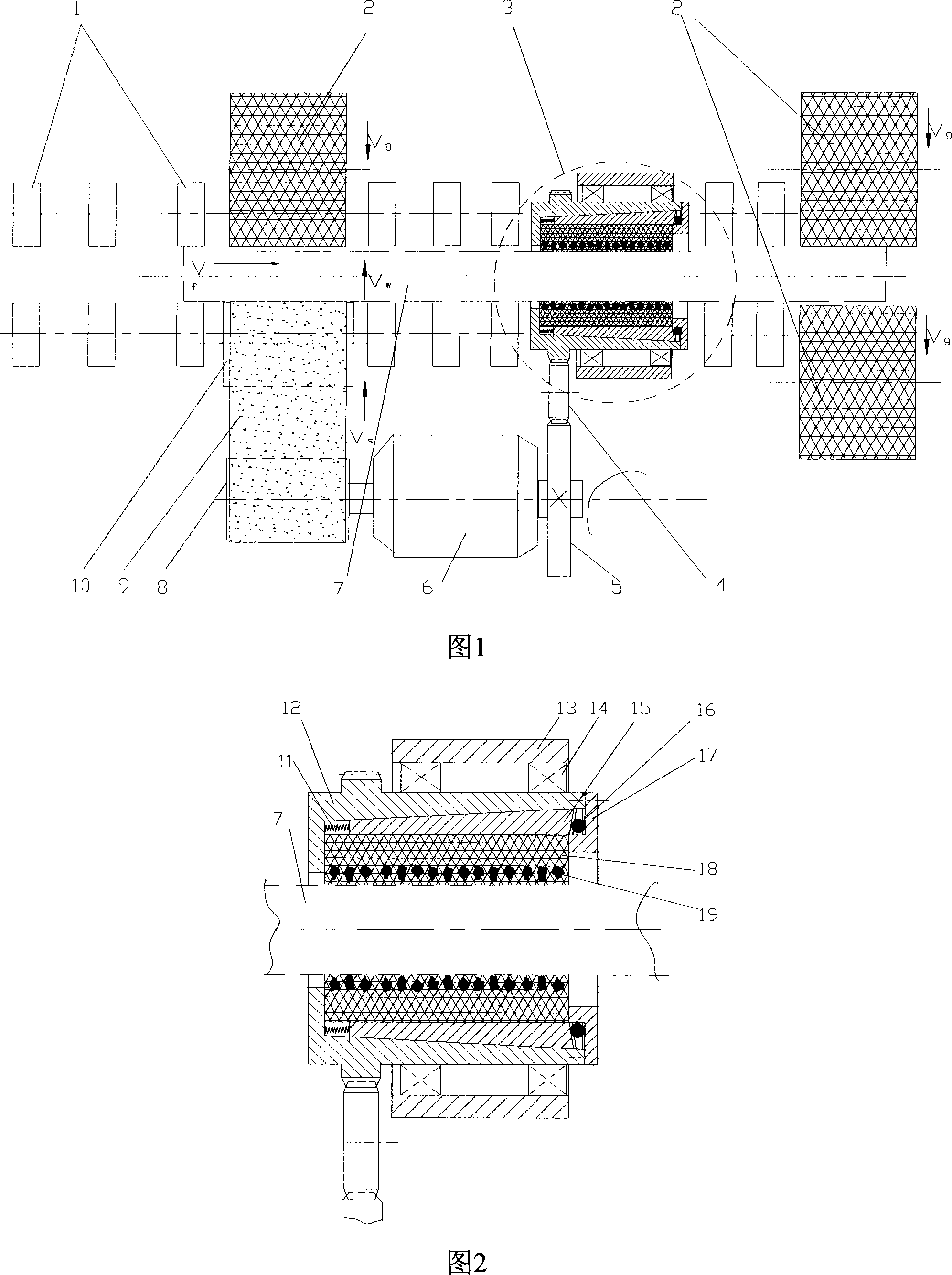

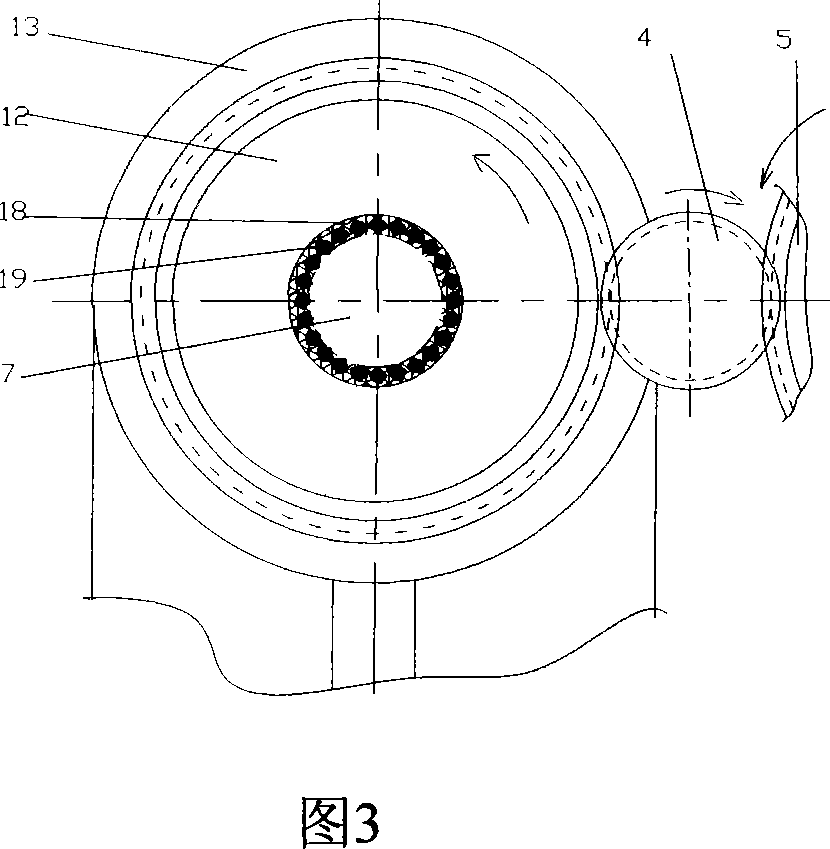

[0028] As shown in Figure 1, a rough / finishing integrated processing device for abrasive belt centerless grinding and polishing, including a workpiece supporting wheel 1, a guide wheel 2, a grinding head 3, a transition gear 4, a fixed gear 5, a two-axis Motor 6, abrasive belt centerless grinding head, one end of the workpiece axial feed direction of the processing device is provided with a guide wheel 2 and an abrasive belt centerless grinding head, and the other end is provided with two guide wheels 2, the guide wheel 2 and the abrasive belt The belt centerless grinding head is perpendicular to the axial feeding direction of the workpiece. The workpiece supporting wheel 1 supports the workpiece 7. The abrasive belt centerless grinding head is composed of the grinding head driving wheel 8, the abrasive belt 9 and the grinding head contact wheel 10. The grinding head drives The wheel 8 is connected with the grinding head contact wheel 10 through the abrasive belt 9 . One end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com