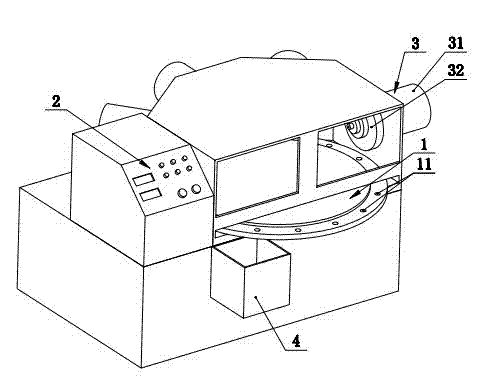

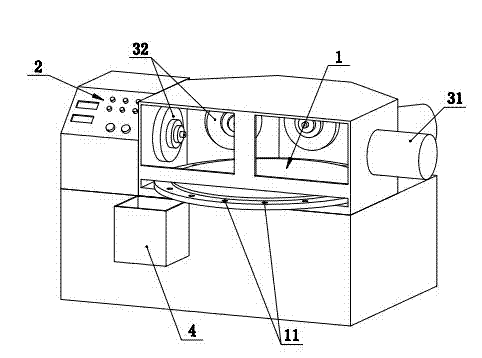

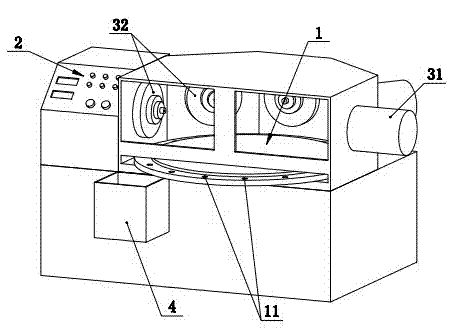

Disc multi-station automatic polishing machine

An automatic polishing, multi-station technology, used in surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of high work intensity, high polishing cost, time-consuming and labor-intensive, etc., to reduce polishing costs and processing. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] like figure 1 , 2 Shown is a disc-type multi-station automatic polishing machine, which includes a disc-shaped worktable 1 that can be controlled to rotate, and a numerical control system 2 that controls the circumferential rotation of the workbench 1. The circumference of the workbench 1 is evenly distributed. There are several processing stations 11 for fixing workpieces to be processed, and several groups of polishing mechanisms 3 are evenly distributed on the upper circumference of the corresponding processing stations 11 of the workbench 1, and the polishing mechanisms 3 include a motor 31 and a sleeve The polishing wheel 32 on the output shaft of the motor 31, and the several polishing wheels 32 in the several groups of polishing mechanisms 3 are polishing wheels 32 of different polishing materials. The plurality of polishing wheels 32 of different polishing materials are distributed counterclockwise from thick to thin, and a storage box 4 for collecting processe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com