Potato chip delivery package sealing performance testing and screening equipment

A technology for sealing detection and screening equipment, applied in sorting and other directions, can solve the problems of air leakage, easy deterioration of potato chips, inability to guarantee taste and integrity, etc., to avoid deterioration, improve anti-corrosion and transportation quality, and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

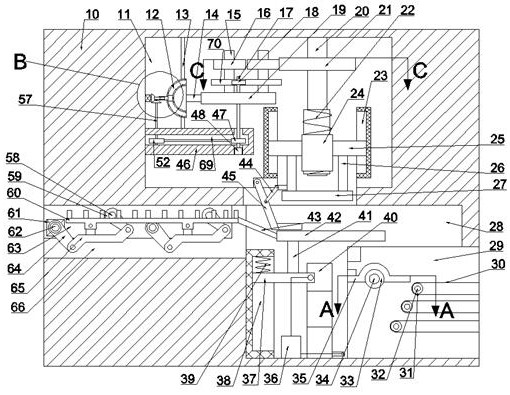

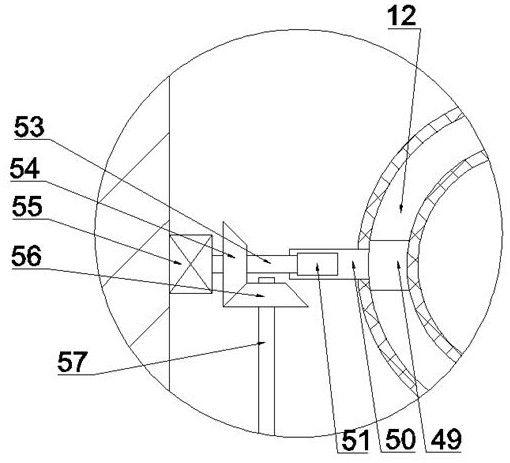

[0014] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

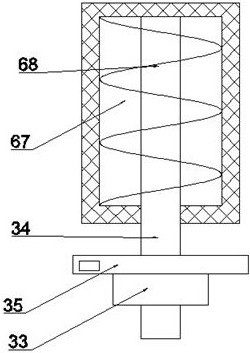

[0015] The airtightness testing and screening equipment for potato chips ex-factory packaging according to the present invention includes a housing 10, a pressure chamber 11 is arranged inside the housing 10, and an active motor 55 is fixed on the left side wall of the pressure chamber 11, The right side of the active motor 55 is rotated with a main motor shaft 53, the left end of the main motor shaft 53 is fixed with a motor bevel gear 54, and the right end of the main motor shaft 53 is fixed with a rear connecting rod 51, and the rear connecting rod The rear side of 51 is fixed with a slider connecting rod 50, the left side of the pressure chamber 11 is fixed with a curved groove pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com