A cooling method and cooling equipment for the manufacture of anti-corrosion steel pipes

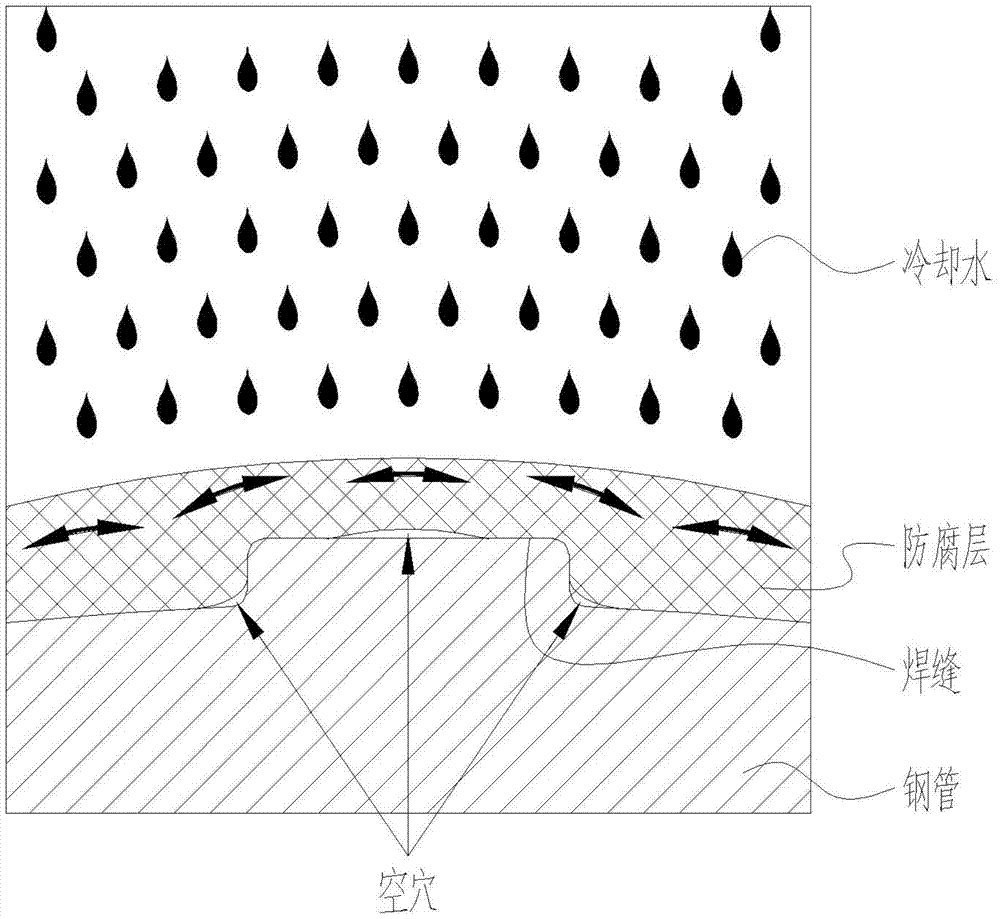

A technology for anti-corrosion steel pipes and cooling equipment, applied in the direction of manufacturing tools, heat treatment equipment, furnace types, etc., can solve problems such as rising costs, anti-corrosion quality defects, etc., and achieve the effects of improving service life, improving the ability to destroy the environment, and eliminating cavities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

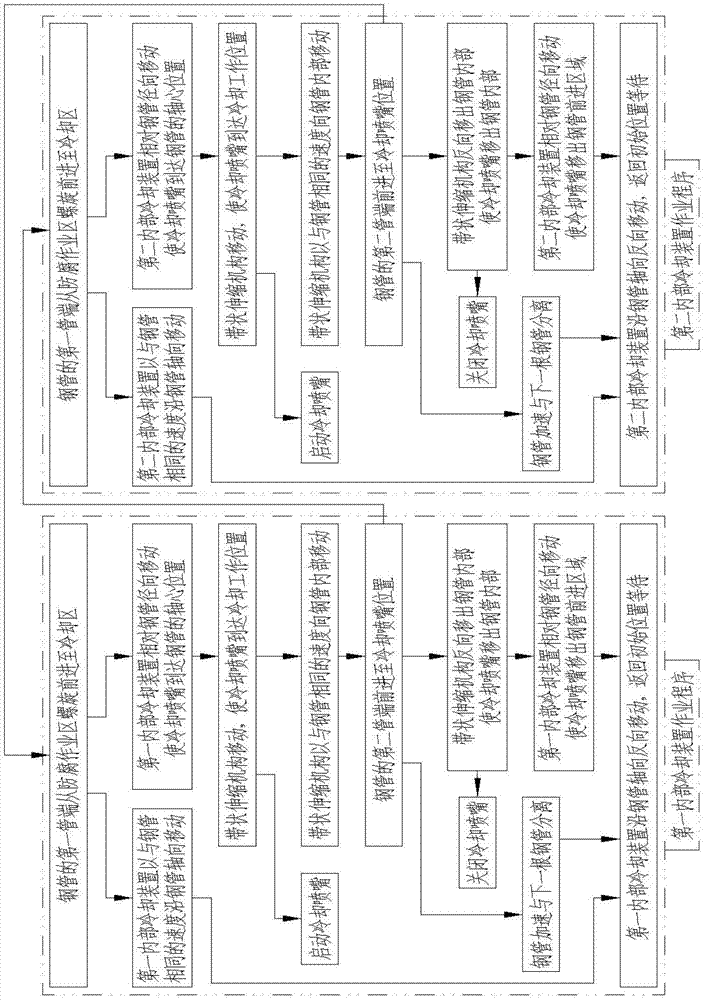

[0040] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims without being limited to the embodiments described herein. In addition, these embodiments are for the purpose of fully disclosing the present invention and facilitating a complete understanding of the scope of the claims by those skilled in the art. For ease of description, the size and relative size of each layer and area in the figure are exaggerated. The same reference numerals refer to the same elements in the figures.

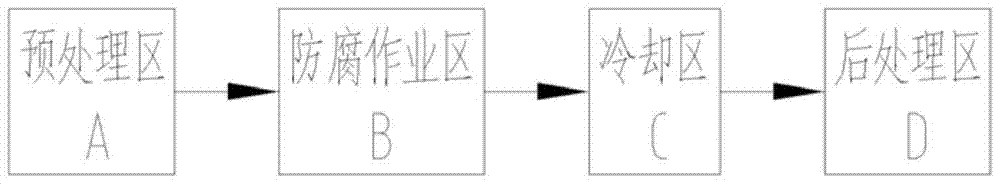

[0041] figure 2 Shown is a schematic diagram of the main functional areas of the anti-corrosion steel pipe production line, including pretreatment area A, anti-corrosion operation area B, cooling area C, and post-treatment area D. Working area B, enter cooling area C. The method that the present invention realizes steel pipe internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com