Anti-corrosion treatment device for ventilation fan blade machining

A technology of anti-corrosion treatment and fan blades, which is applied in the direction of spraying devices, pre-treatment surfaces, liquid spraying devices, etc., can solve problems such as collection and transfer troubles, overall efficiency limitations, and effects on painting treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

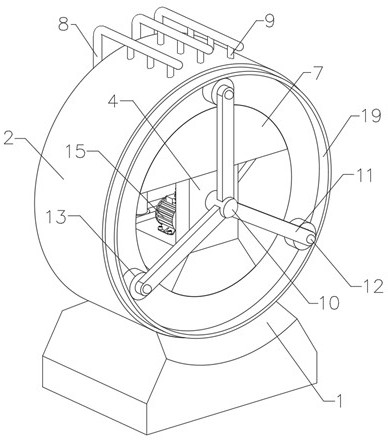

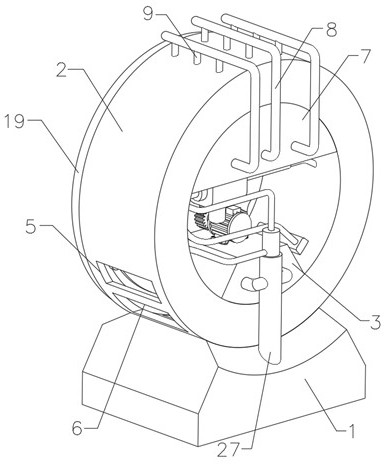

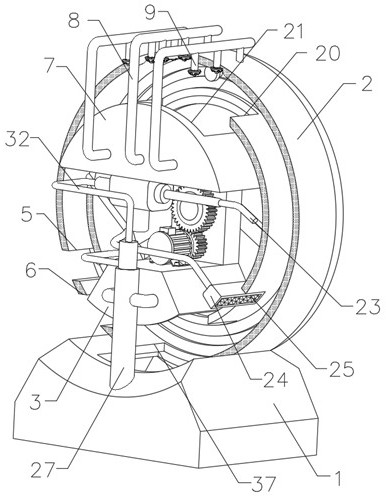

[0030] refer to Figure 1-4 , a kind of anticorrosion treatment device for fan blade processing, comprising a water tank 1, the upper end of the water tank 1 is fixed with a treatment box 2, the lower part of the inner side of the treatment box 2 is fixed with a building platform 3, the upper end of the building platform 3 is provided with a drive mechanism, and the treatment box The peripheral outer wall of 2 runs through and is provided with feed inlet 6 and discharge port 5, and the upper part of processing box 2 inner side is fixed with paint material box 7, and the upper wall of paint material box 7 runs through and is provided with reflux groove 21, and the inner wall of processing box 2 A collection tank 20 connected with the return tank 21 is opened through, and a plurality of delivery pipes 8 are inserted through the side wall of the paint tank 7, and a plurality of spray heads 9 are fixed through the side wall of each delivery pipe 8, each The spraying heads 9 all pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com