A kind of phosphorus spraying film-forming liquid and phosphorus spraying process

A technology of film-forming liquid and phosphorus spraying, which is applied in the coating process of metal materials, etc., can solve the problems of tissue change and mechanical performance surface treatment difficulties, troubles in scientific research and production, and difficulties in phosphating and film formation, so as to improve tactical performance indicators and storage period, promote the level of surface technology, and improve the effect of anti-corrosion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

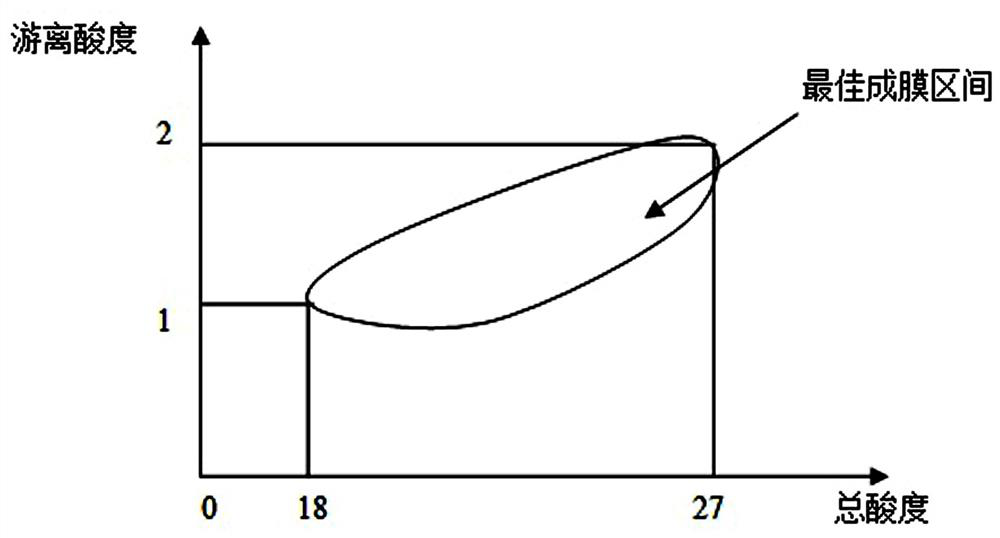

[0035] Example 1: After degreasing and surface-conditioning the elastic body made of 35CrMnSiA and with a tensile strength of 1400MPa-1500MPa (its hardness is 41HRC-46HRC), spray phosphating treatment is carried out in the bath liquid of the following composition. The process parameters : Zn 2+ : 4000 ppm, Mn 2+ : 300 ppm, F - : 800 ppm, MoO 4 2- : 250 ppm, NO 3 - : 8000 ppm, PO 4 3- : 11000ppm. Composite accelerator (nitrite and sulfonate) A 300ppm, additive (organic salt) B 800ppm to adjust the free acid Fa of the bath: 1.0 points, the total acidity Ta: 18 points, Ta / Fa=15 or so, accelerator 5 o'clock, temperature: 43℃~45℃, pump gauge pressure: 0.04MPa~0.05MPa. Under these conditions, a light gray phosphating film layer is obtained, and the phosphating film weighs 2.5g / m 2 ~3.5g / m 2 (The drawings require not less than 1.5g / m 2 ), under 26°C environmental conditions, the copper sulfate drop test is 45s (the product drawing requires 30s); the coating is coated wit...

Embodiment 2

[0036] Example 2: After degreasing and surface conditioning, the elastic body with a material of 35CrMnSiA and a tensile strength of 1400MPa-1500MPa (hardness 41HRC-46HRC) is treated in the following spray phosphating bath. Spray phosphating process parameters: Zn 2+ : 5000ppm, Mn 2+ : 400 ppm, F - : 1000 ppm, MoO 4 2- : 300ppm, NO 3 - : 10000 ppm, PO 4 3- : 13000ppm. Composite accelerator (nitrite and sulfonate) A 400ppm, additive (organic salt) B 1000ppm, Fa: 1.4 points, Ta: 20 points Ta / Fa=15 or so, accelerator 7 points, temperature: 44℃~46 ℃, pump gauge pressure: 0.05MPa~0.06MPa. Under these conditions, a light gray phosphating film layer is obtained with a film weight of 3.5g / m 2 (Product drawings require not less than 1.5g / m 2 ), under 26°C environmental conditions, the copper sulfate spot test is 47s (30s as required by the drawing); after 96 hours of salt spray test with 5403 series military paint (coating thickness 30μm), the coating has no blistering, no ...

Embodiment 3

[0037] Example 3: After degreasing and surface conditioning, the elastic body made of 35CrMnSiA and tensile strength of 1400MPa-1500MPa (hardness 41HRC-46HRC) is treated in the following spray phosphating bath. Spray phosphating process parameters: Zn 2+ : 6000ppm, Mn 2+ : 450 ppm, F - : 1200 ppm, MoO 4 2- : 350ppm, NO 3 - : 12000 ppm, PO 4 3- : 16000ppm. Composite accelerator (nitrite and sulfonate) A 600ppm, additive (organic salt) B 1200ppm, Fa: 1.8 points, Ta: 26 points Ta / Fa=15 or so, accelerator 9 points, temperature: 46℃~ 48°C, pump gauge pressure: 0.06MPa~0.07MPa. Under these conditions, a gray phosphating film with a film weight of 3.5g / m 2 (Product drawings require not less than 1.5g / m 2 ), under 26°C environmental conditions, the copper sulfate spot test is 50s (the product drawing requires 30s); after 96 hours of salt spray test with 5403 series military paint (coating thickness 30μm), the coating does not blister, fall off, or Rust (the product pictur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| film density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com