Wrapping belt for pipeline repaired opening corrosion prevention and construction method

A construction method and technology of wrapping tape, applied in the direction of pipe elements, pipes/pipe joints/pipe fittings, coatings, etc., can solve the problems of low tensile strength of PE layer, affecting the service life of pipes, unstable peel strength, etc. Reduce construction labor intensity, eliminate differences in human operation, and improve the effect of anti-corrosion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

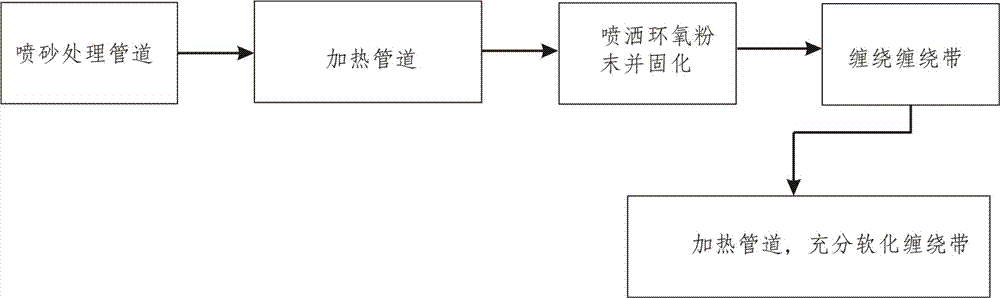

Method used

Image

Examples

Embodiment 1

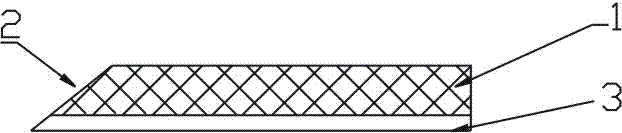

[0028] Embodiment 1: as figure 1 , 3 Shown: the present invention provides a kind of wrapping tape for pipe joint anticorrosion, the wrapping tape is composed of hot melt adhesive and PE material layer, PE material layer 1, hot melt adhesive layer 3 successively from the surface to the bottom, this embodiment Set any lengthwise side of the wrapping tape as a slope 2, and the slope slopes downward from the PE material layer 1 to the hot melt adhesive layer 3, the inclination angle is set to 8°, and the wrapping tape width is set to 240mm. Due to the softness of the hot melt adhesive layer 3 of the final product, the edge of the hot melt adhesive will be jagged when cutting, and the appearance of the product is not beautiful enough, but it does not affect the quality of the product. Forms a seamless wrap.

[0029] In the specific construction, special adhesives with better performance than hot melt adhesives are selected as the carrier between the epoxy primer and the winding ...

Embodiment 2

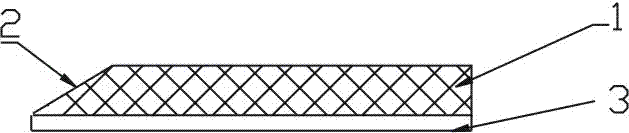

[0035] Embodiment 2: as figure 2 , 3 Shown: the present invention provides a kind of wrapping tape for pipeline joint anticorrosion, and this wrapping tape is made up of hot-melt adhesive layer and PE material layer, is PE material layer 1 and hot-melt adhesive layer 3 successively from surface to bottom, this embodiment For example, set the side of any length direction of the wrapping tape as slope 2, and the slope only contains the PE material layer, and the hot melt adhesive layer remains the same; at the same time, the slope direction of the slope is downward from the direction indicating the bottom surface , the inclination angle is set to 12°, and the width of the wrapping tape is set to 80mm. The produced winding tape has neat sides and beautiful appearance.

[0036] The specific method is the same as in embodiment 1, except that the winding tape of the last circle covers half the width of the winding tape of the last circle when winding.

[0037] In Example 1 and E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com