Application of Solvent-free Two-component Epoxy Coatings in Pipeline Coating and Anticorrosion

An epoxy coating, two-component technology, applied in the field of coatings, can solve problems such as weak adhesion, achieve the effect of improving initial adhesion and durable adhesion, and improving the quality of joint anticorrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

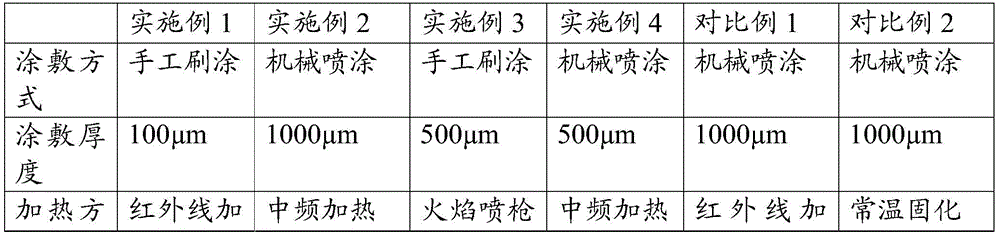

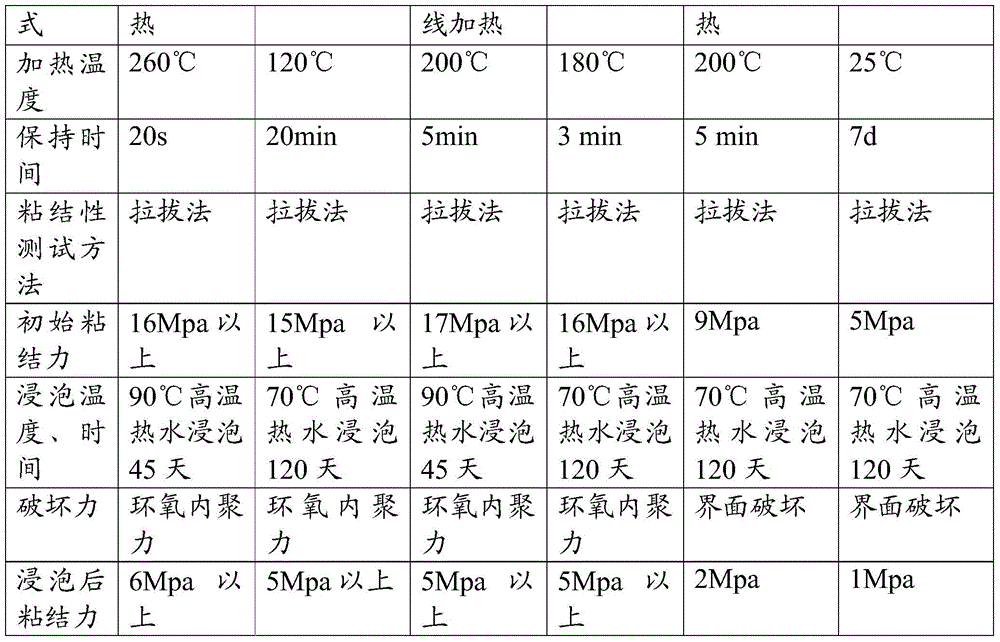

Examples

Embodiment 1

[0040] The embodiment of the present invention provides a solvent-free two-component epoxy coating for jointing anticorrosion, the epoxy coating is composed of A component and B component, and the A component and the B component The weight ratio is: 100:15; the composition and weight percentage of the A component are: bisphenol A epoxy resin (trade name E51) 15%, novolac epoxy resin (trade name F51) 20%, butyl Glycidyl ether 5%, fatty acid modified polyester dispersant (EFKA6230) 0.3%, polysiloxane defoamer (Deqian 6800) 0.8%, polysiloxane leveling agent (EFKA3239) 0.6%, trimer Aluminum dihydrogen phosphate 15%, carbon black 0.3%, mica powder 13%, talcum powder 15%, barium sulfate 15%; the composition and weight percentage of the B component are: polyamide (purchased from: American Air Chemicals ; product model: Ancamide2353) 25%, phenalkamine (purchased from: American Air Chemicals; product model: Ancamide2724) 50%, trimethylhexamethylene hexamethylenediamine 25%.

Embodiment 2

[0042] The embodiment of the present invention provides a solvent-free two-component epoxy coating for jointing anticorrosion, the epoxy coating is composed of A component and B component, and the A component and the B component The weight ratio is: 100:25; the composition and weight percentage of the A component are: bisphenol A epoxy resin (trade name E51) 35%, novolac epoxy resin (trade name F51) 5%, benzene Glycidyl ether 12%, fatty acid modified polyester dispersant (EFKA6230) 0.6%, polysiloxane defoamer (Deqian 6800) 0.7%, polysiloxane leveling agent (EFKA3239) 0.5%, trimer Aluminum dihydrogen phosphate 10%, carbon black 0.2%, mica powder 10%, talc powder 15%, barium sulfate 11%; the composition and weight percentage of the B component are: polyamide (purchased from: American Air Chemicals ; product model: Ancamide2643) 50%, phenalkamine (purchased from: American Air Chemicals; product model: Ancamide2724) 35%, triethylenetetramine 15%.

Embodiment 3

[0044] The embodiment of the present invention provides a solvent-free two-component epoxy coating for jointing anticorrosion, the epoxy coating is composed of A component and B component, and the A component and the B component The weight ratio is: 100:50; the composition and weight percentage of the A component are: bisphenol A epoxy resin (trade name E51) 35%, novolac epoxy resin (trade name F51) 15%, propylene Glycidyl ether 5%, fatty acid modified polyester dispersant (EFKA6230) 0.3%, polysiloxane defoamer (Deqian 6800) 0.8%, polysiloxane leveling agent (EFKA3239) 0.6%, trimer Aluminum dihydrogen phosphate 10%, carbon black 0.3%, mica powder 8%, talcum powder 15%, barium sulfate 10%; the composition and weight percentage of the B component are: polyamide (purchased from: American Air Chemicals ; product model: Ancamide2643) 75%, phenalkamine (purchased from: American Airline; product model: Ancamide2724) 20%, trimethylhexamethylene hexamethylenediamine 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com