Antiseptic operation system of hot bending bent pipe and operation method thereof

An operating system and bending technology, applied in the direction of pipeline anti-corrosion/anti-rust protection, damage protection, pipeline protection, etc., can solve the problems of inability to meet anti-corrosion production, waste of raw materials, low production speed, etc. The effect of layer PE anti-corrosion production operation time, reducing raw material waste and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

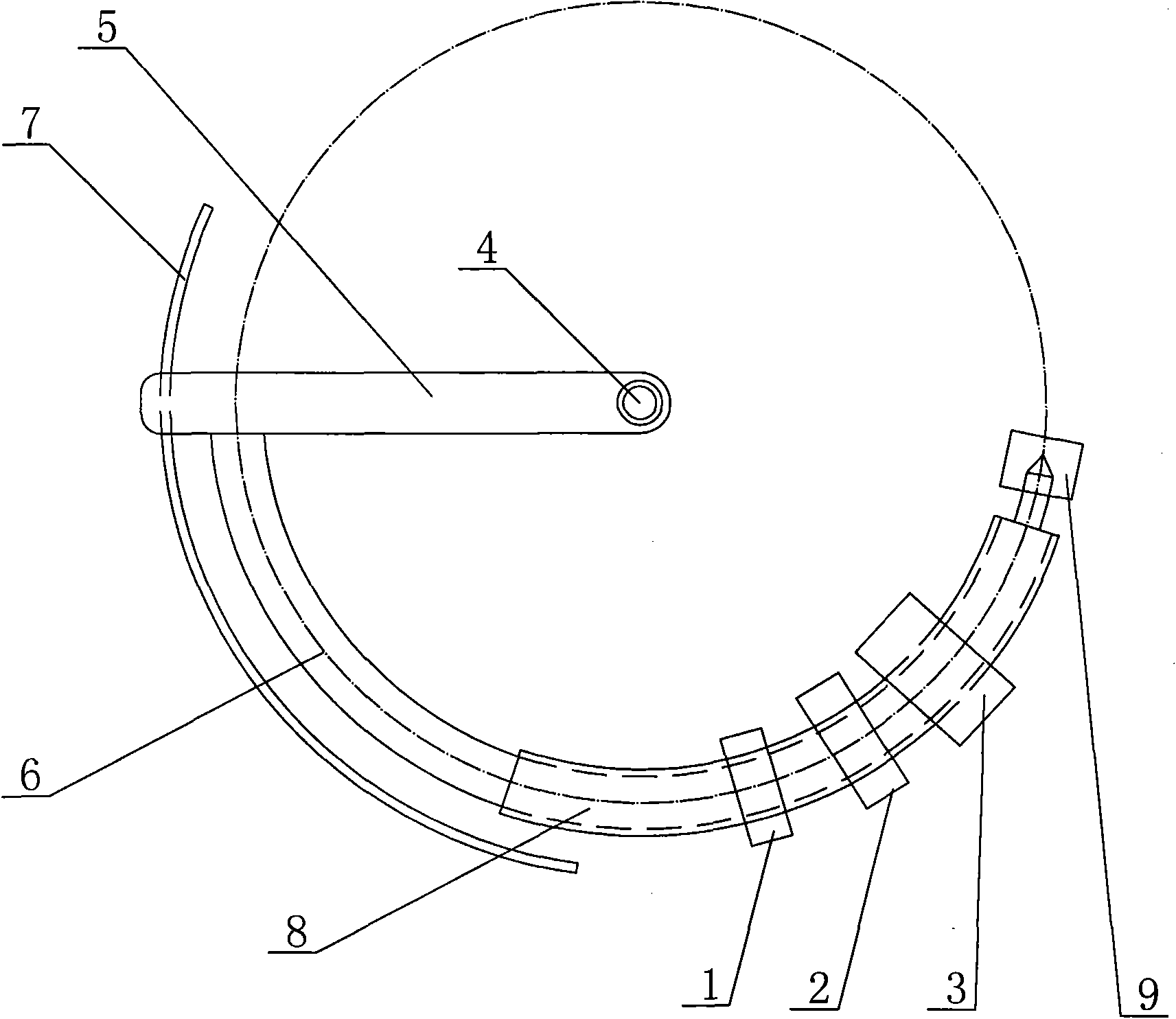

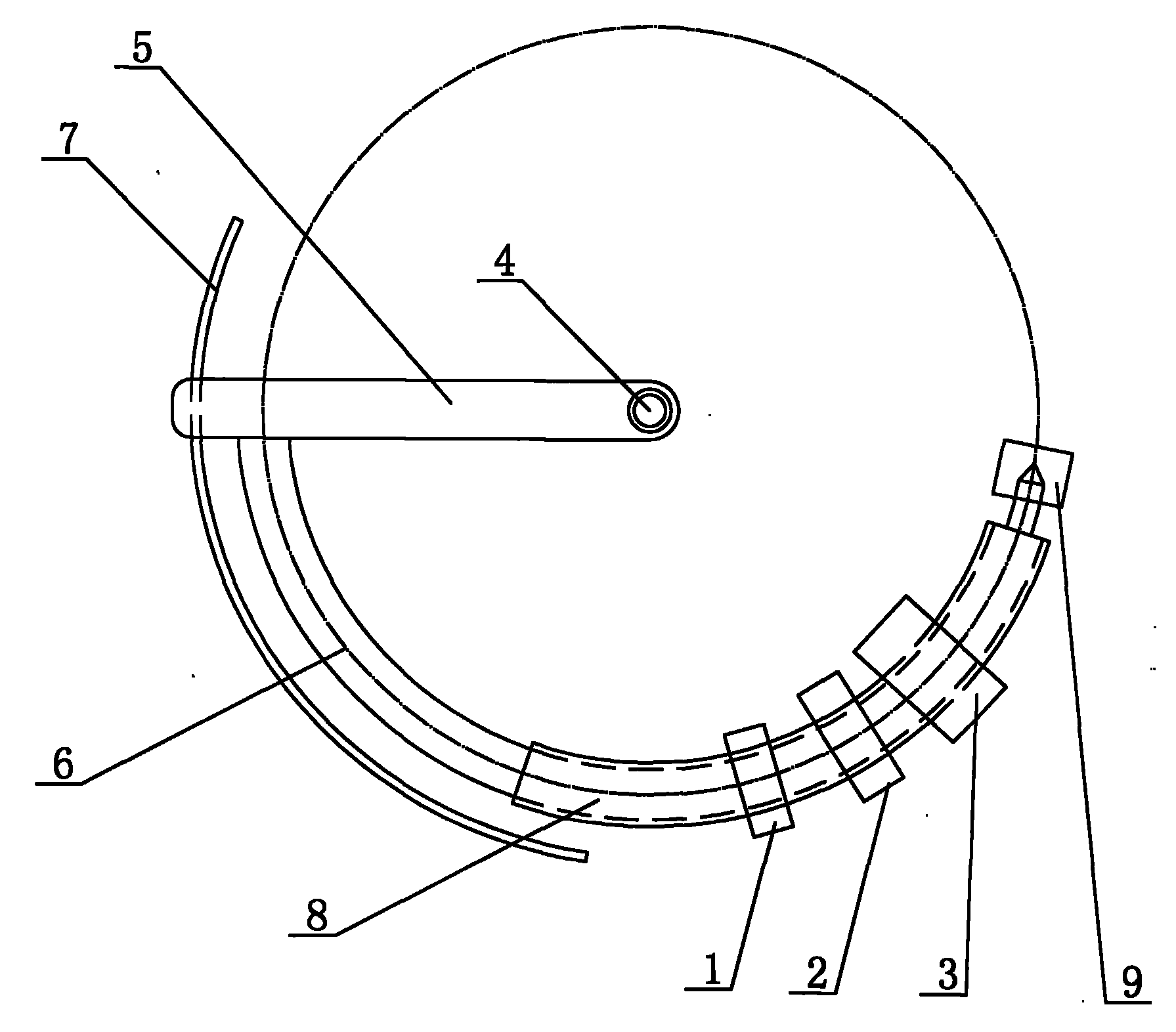

[0034] An anti-corrosion operation system for hot-bent pipes, including a loading and unloading platform, a medium-frequency heating device 1, a powder spraying device 2, a winding device 3, and a cooling device, as well as a rotating cantilever, which includes a rotating shaft 4 Rotating swivel beam 5 and arc-shaped cantilever 6 arranged on the swivel beam 5, one end of the swivel beam 5 is installed on the rotary shaft 4, the other end is supported on the arc-shaped track 7, and the hot-bending elbow 8 is fixedly arranged on the arc On the curved cantilever 6, the intermediate frequency heating device 1, the powder coating device 2, the winding device 3 and the cooling device are arranged along the trajectory of the arc cantilever 6, and the hot bending elbow 8 is sequentially connected with the intermediate frequency heating device 1, the powder coating device 2, the winding The device 3 cooperates with the cooling device. That is, the hot bend pipe 8 is first heated by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com