Automatic and rapid detection method and system for trace iron ions in power plant water vapor and application

A power plant water vapor and detection system technology, which is applied in the direction of color/spectral characteristic measurement, analysis through chemical reaction of materials, instruments, etc., can solve problems such as little expansion potential, increasing difficulty of online monitoring, and narrow linear range of measurement

Active Publication Date: 2016-03-09

NORTH CHINA ELECTRICAL POWER RES INST +1

View PDF3 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0017] Because iron has paramagnetism, this method is rarely used in this field to measure the iron content in water. Usually, the opposite is done, and the method of fluorescence quenching is used to indirectly measure the iron content. However, this method requires the applicatio

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Login to View More

Abstract

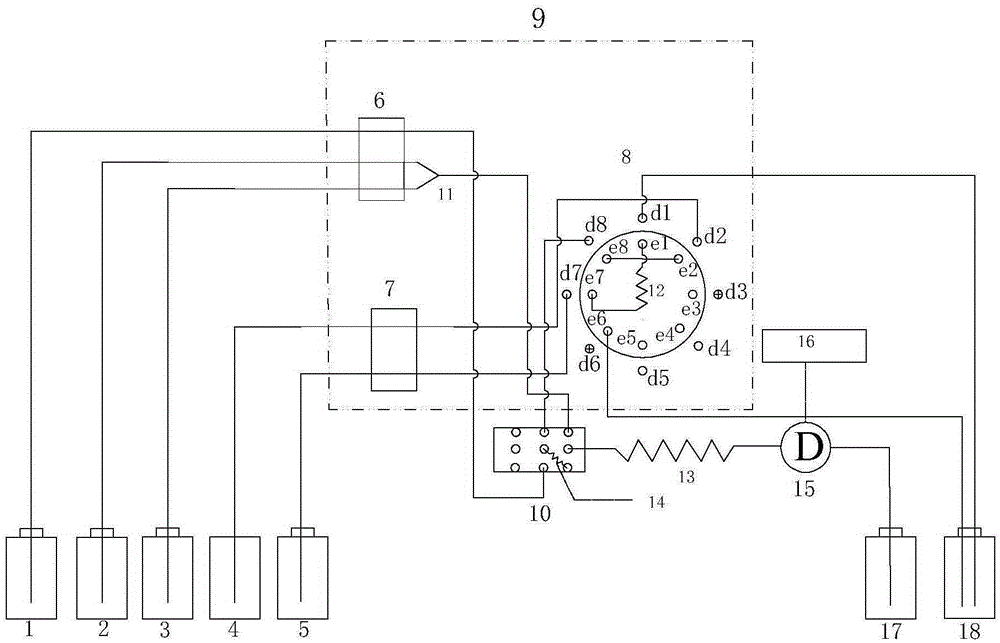

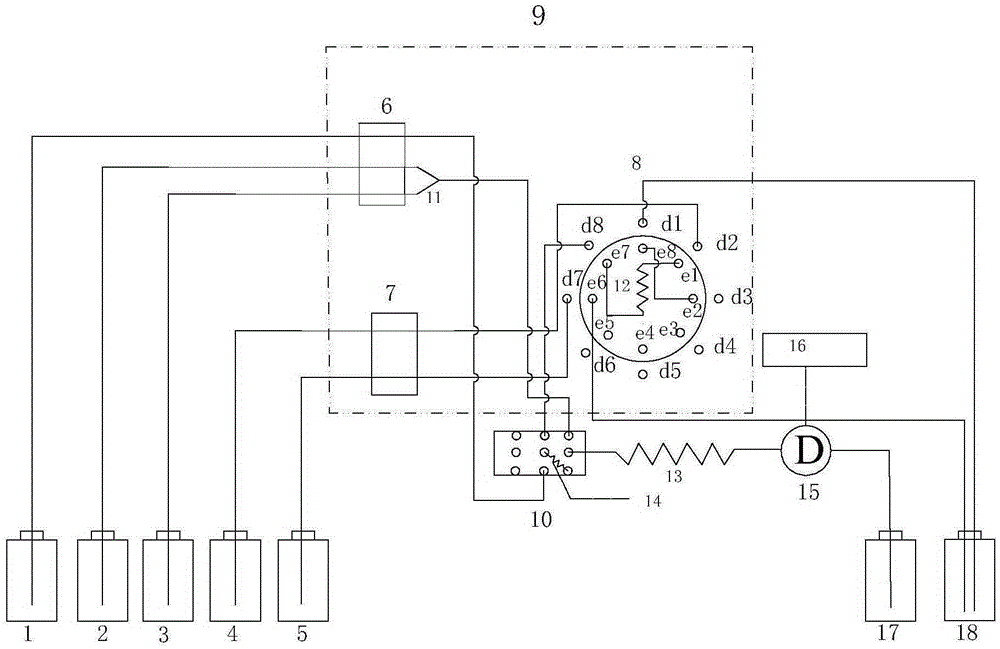

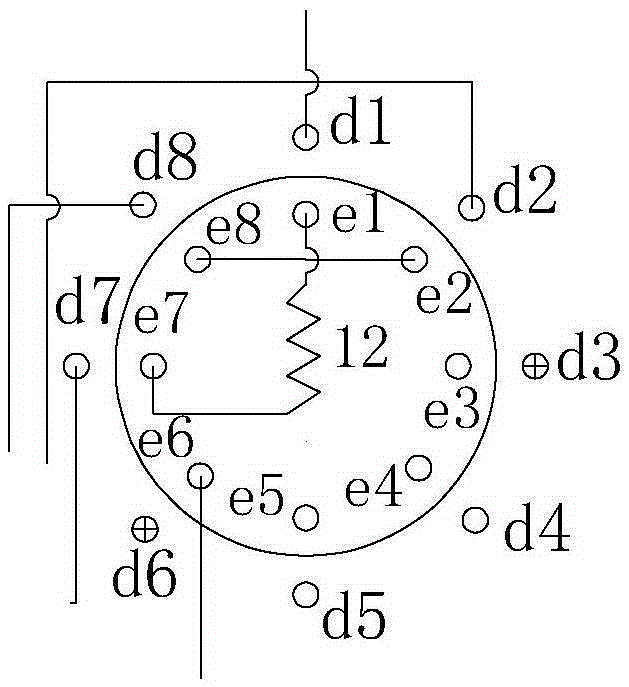

The invention provides an automatic and rapid detection method and system for trace iron ions in power plant water vapor and application. The system comprises a reducing reagent bottle (1), a color reagent bottle (2), a buffer liquid bottle (3), a current-carrying bottle (4), a water sample bottle (5), a flow injection analyzer (9), a combination module (10), a Y-type tee joint (11), a color reaction disk tube (13), a reducing reaction disk tube (14) and a detection device (15), wherein the flow injection analyzer (9) comprises a main pump (6), an auxiliary pump (7), an eight-channel sampling valve (8) and a sampling ring (12). The invention further provides an automatic and rapid detection method for trace iron ions in power plant water vapor and application of the method in detection of trace iron ions in power plant water vapor. The method and the system provided by the invention can realize automatic, rapid, accurate and reliable determination of trace iron ions in power plant water vapor, and the detection limit is 0.5mu g/L.

Description

technical field [0001] The invention relates to the detection of water vapor in a power plant, in particular to an automatic and rapid detection method, system and application of trace iron ions in the water vapor of a power plant. Background technique [0002] The iron content of the water vapor system of the power plant is a very important monitoring index. It is an important basis for evaluating the corrosion and scaling of the thermal system of the operating unit, and it is one of the regular monitoring indicators for the daily production of the power plant. [0003] At present, the methods for determining total iron in power production feed water and furnace water are o-phenanthroline spectrophotometry (GB / T14427-2008) and graphite furnace atomic absorption method (DL / T955-2005). O-phenanthroline spectrophotometry is a traditional manual analysis method. This method is complicated to operate and low in analysis efficiency. During the digestion process of water samples, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N35/00G01N21/78G01N21/31

CPCG01N21/31G01N21/78G01N35/00584

Inventor 星成霞王应高刘郦雅李炜

Owner NORTH CHINA ELECTRICAL POWER RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com