One-pot technology of 4'-methyl-2-carboxylate biphenyl

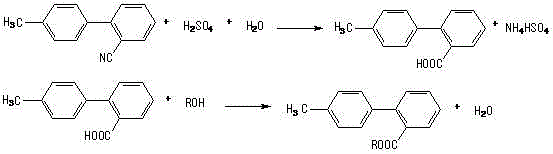

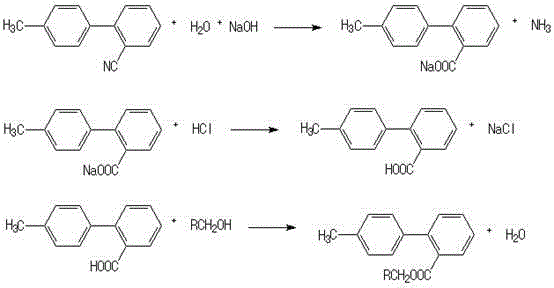

The technology of ester biphenyl and cyano biphenyl is applied in the field of 4'-methyl-2-carboxylate biphenyl one-pot process, which can solve the problems of high labor intensity, long time consumption, environmental pollution of material circulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1. Install a reflux condenser with condensed water at or below normal temperature on the 250ml four-neck flask with electric PTFE stirring, a thermometer at 0-200°C, and a matching adjustable constant temperature electric heating oil bath or adjustable Constant temperature electric heating mantle and other heating devices. Add 12.5 grams of 4'-methyl-2-cyanobiphenyl and 30 grams of 30% dilute sulfuric acid into a four-necked flask, heat, and reflux at a temperature of 106 to 113°C for 24 hours; then cool down and add toluene (content 99%) 20 grams, install a 10ml water separator with a scale, heat and reflux to divide the water until about 18.5ml of water is separated, stop heating and cool down, and release the water layer in the water separator; when the temperature drops to normal temperature, Add 5 grams of methanol, heat and continue to reflux, react for 8 hours, and steam the remaining methanol. At this time, the reflux temperature will reach 115° C., end...

Embodiment 2

[0017] Example 2. On the 250ml four-necked flask with electric PTFE stirring, install a reflux condenser with condensed water at or below normal temperature, a thermometer at 0-200°C, and a matching adjustable constant temperature electric heating oil bath or adjustable Constant temperature electric heating mantle and other heating devices. Add 12.5 grams of 4′-methyl-2-cyanobiphenyl, 15 grams of 60% dilute sulfuric acid and 20 grams of toluene (content 99%) into a four-neck flask, heat, and reflux at a temperature of 110 to 115 ° C for hydrolysis reaction 24 hours; then lower the temperature, install a 10ml water separator with a scale, heat and reflux to divide the water until about 3.5ml of water is separated, stop heating and cool down, and release the water layer in the water separator; when the temperature drops to normal temperature, Add 5 grams of methanol, heat and continue to reflux, react for 8 hours, and steam the remaining methanol. At this time, the reflux tempe...

Embodiment 3

[0019] Example 3. On the 250ml four-necked flask with electric PTFE stirring, install a reflux condenser with condensed water at or below normal temperature, a thermometer at 0-200°C, and a matching adjustable constant temperature electric heating oil bath or adjustable Constant temperature electric heating mantle and other heating devices. Add 12.5 grams of 4′-methyl-2-cyanobiphenyl, 12 grams of 75% dilute sulfuric acid and 20 grams of toluene (content 99%) into a four-neck flask, heat, and reflux at a temperature of 110 to 115 ° C for hydrolysis reaction 24 hours; then lower the temperature, install a 10ml water separator with a scale, heat and reflux to divide the water until about 0.5ml of water is separated, stop heating and cool down, and release the water layer in the water separator; when the temperature drops to normal temperature, Add 5 grams of methanol, heat and continue to reflux, react for 8 hours, and steam the remaining methanol. At this time, the reflux tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com