Prefabricated slab transportation frame

A technology for transporting racks and prefabricated panels, applied in the directions of transportation and packaging, external frames, packaging, etc., can solve the problems of inconvenient construction, increase costs, and partially suspended floors, avoid secondary or multiple transfers, and save yard waste. space and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

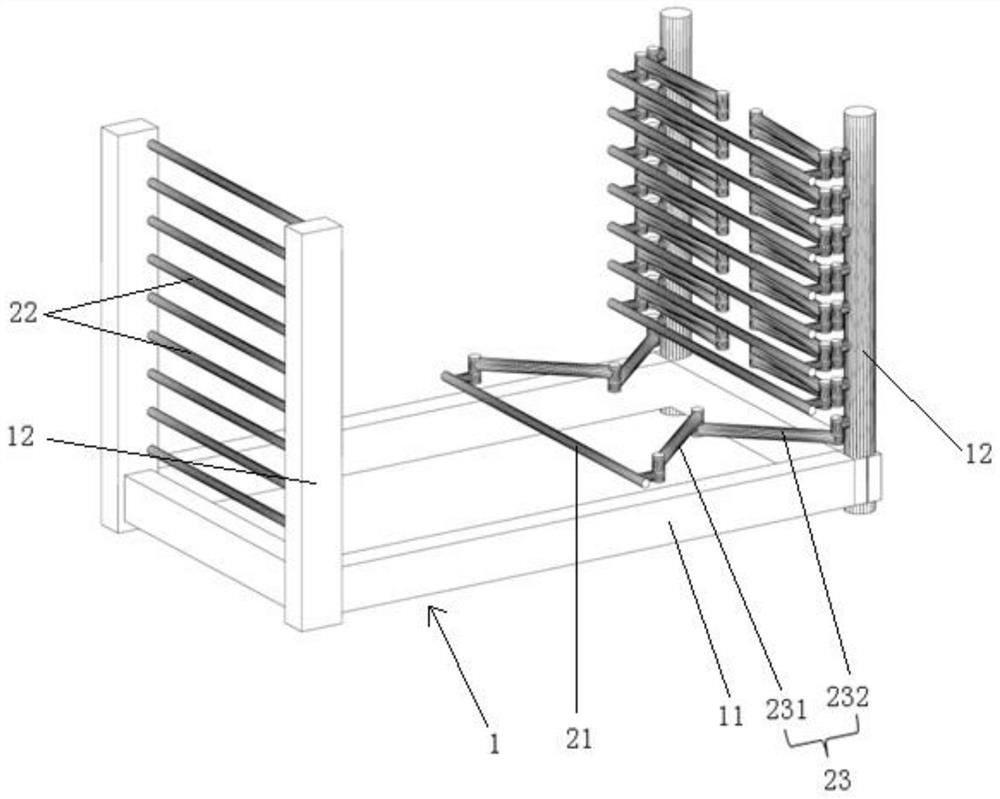

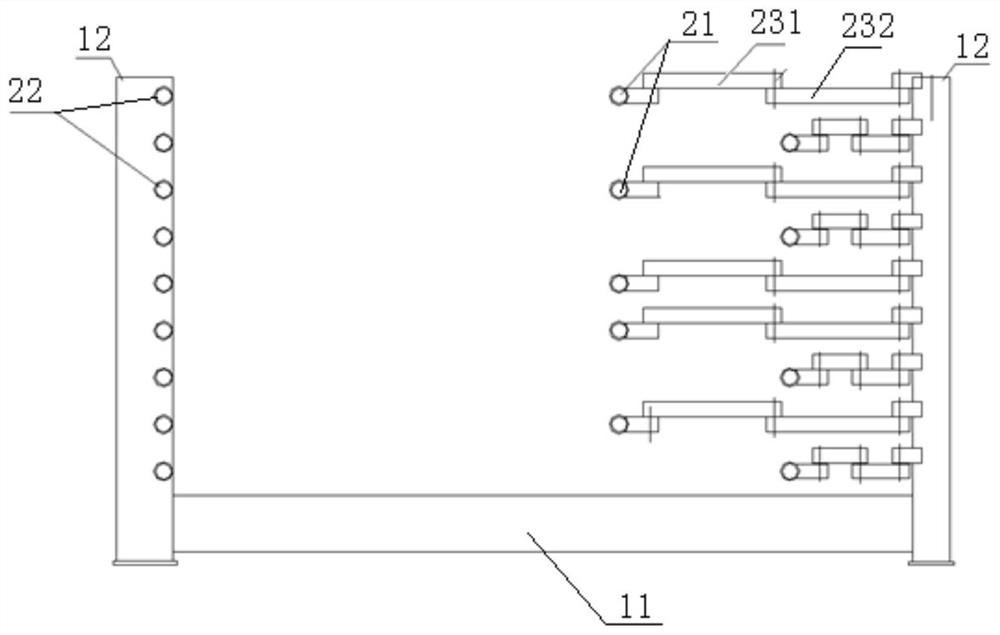

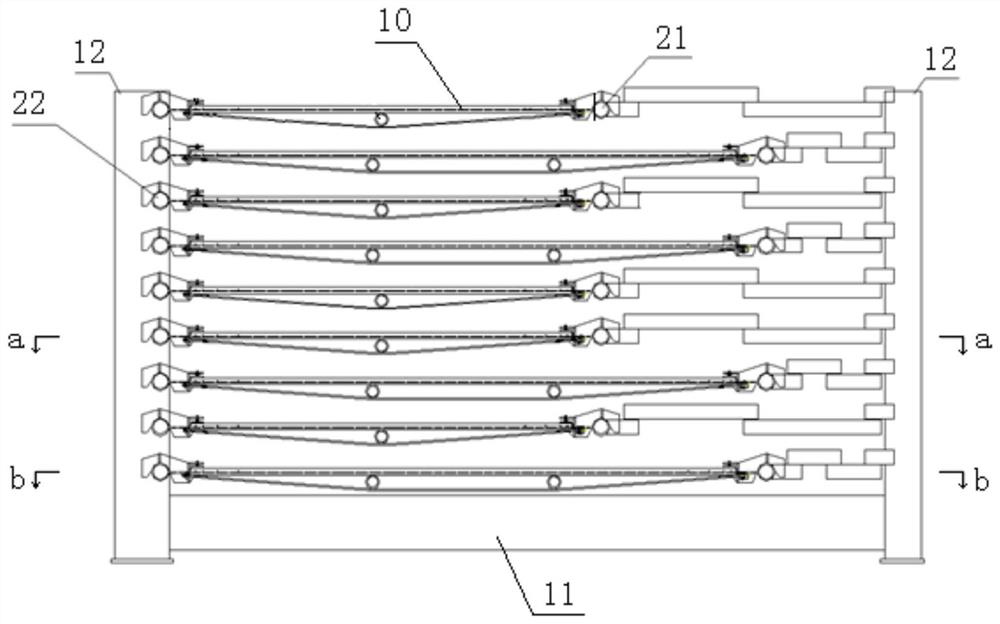

[0019] Refer to attached figure 1 and 2 As shown, the prefabricated board transportation frame of this embodiment includes a frame body 1 and two oppositely arranged support rods arranged on the frame body 1, one of which is a mobile support rod 21, and the mobile support rod 21 is relatively opposite to the other. The fixed support rods 22 telescopically move to realize the adjustment of the distance between the two support rods, so as to adapt to the support and fixation of prefabricated panels of different sizes.

[0020] In this embodiment, the frame body 1 includes a square frame base 11 and uprights 12 vertically arranged at the four corners of the base, and a plurality of parallel fixed supports are arranged between the two uprights 12 on one side of the base 11 Rods 22, and the positions opposite to each fixed support rod 22 are equipped with mobile support rods 21, and the two ends of the mobile support rods 21 are respectively connected to the two vertical arms on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com