Typesetting and stitch welding all-in-one machine

An all-in-one machine and camera technology, applied in welding equipment, conveyor objects, semiconductor devices, etc., can solve the problems of high equipment cost, complicated process, and multiple transfer of product quality in battery strings, so as to reduce equipment cost and improve automation , to avoid the effect of multiple transfers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the above objects, features and advantages of the present invention more clearly understood, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

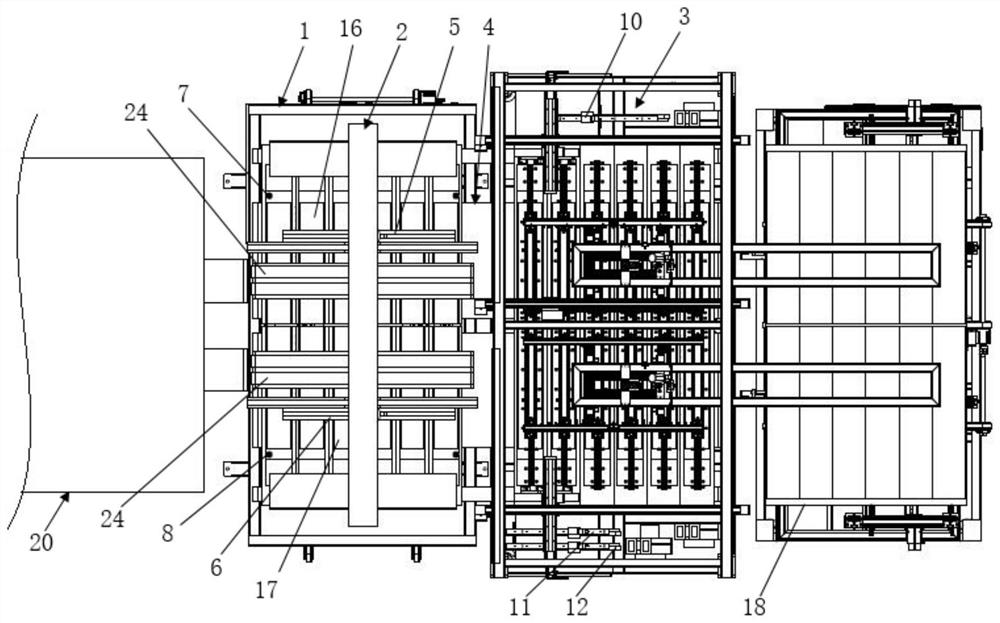

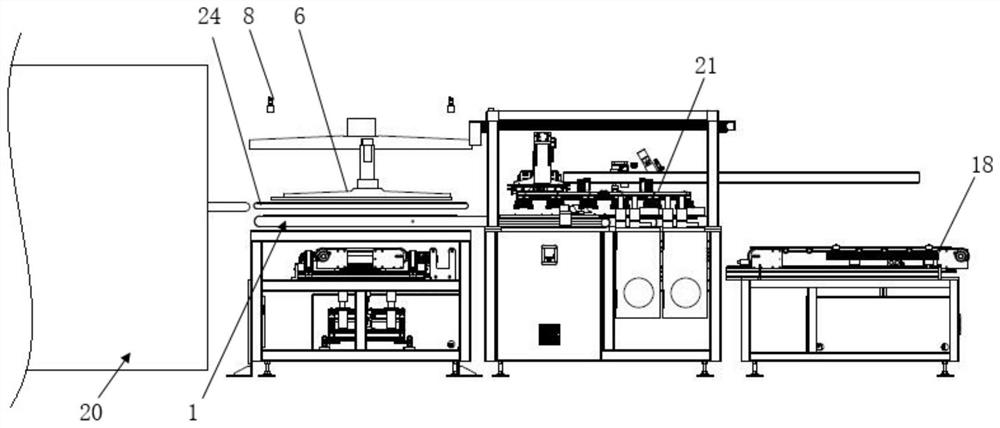

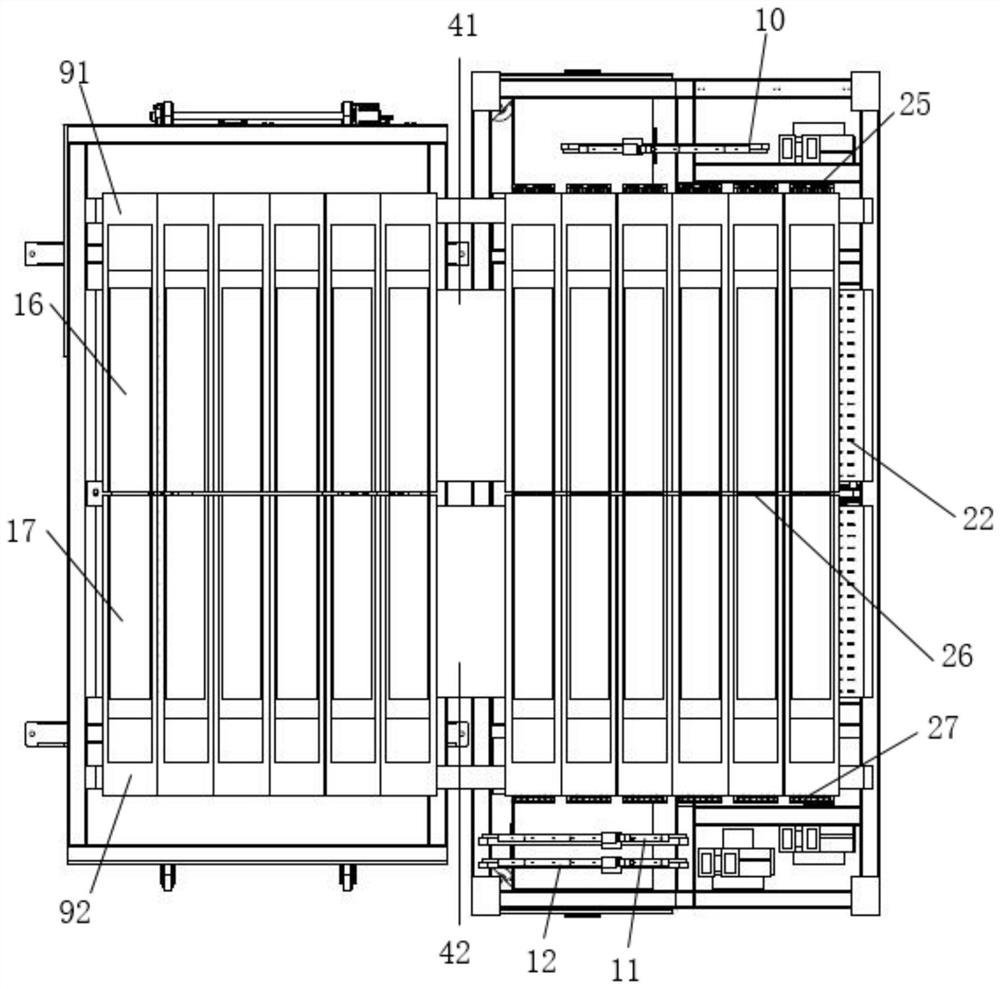

[0042] like Figure 1 to Figure 5 As shown, the present invention is an integrated machine for typesetting and stitching, which is used for typesetting of photovoltaic cell strings and welding of bus bars.

[0043] like figure 1 As shown, the present application provides an all-in-one typesetting and stitching welding machine, which includes a conveying part 1, a typesetting part 2 and a stitching part 3; the typesetting part 2 is arranged at the typesetting station, and the typesetting part 2 is used for picking up The battery strings are typeset to the feeding end of the conveying part 1 according to a predetermined typesetting method; After the assembly, the conveying part 1 conveys the battery strings to the welding statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com