Bag clamping device realizing movable clamping through bag sleeving ring

A clamping device and bagging technology, applied in the field of mechanical spare parts, can solve the problems of huge workload, manual labor, and waste of labor for grain peeling workers, avoiding multiple transfers, stable clamping process, and convenient installation and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

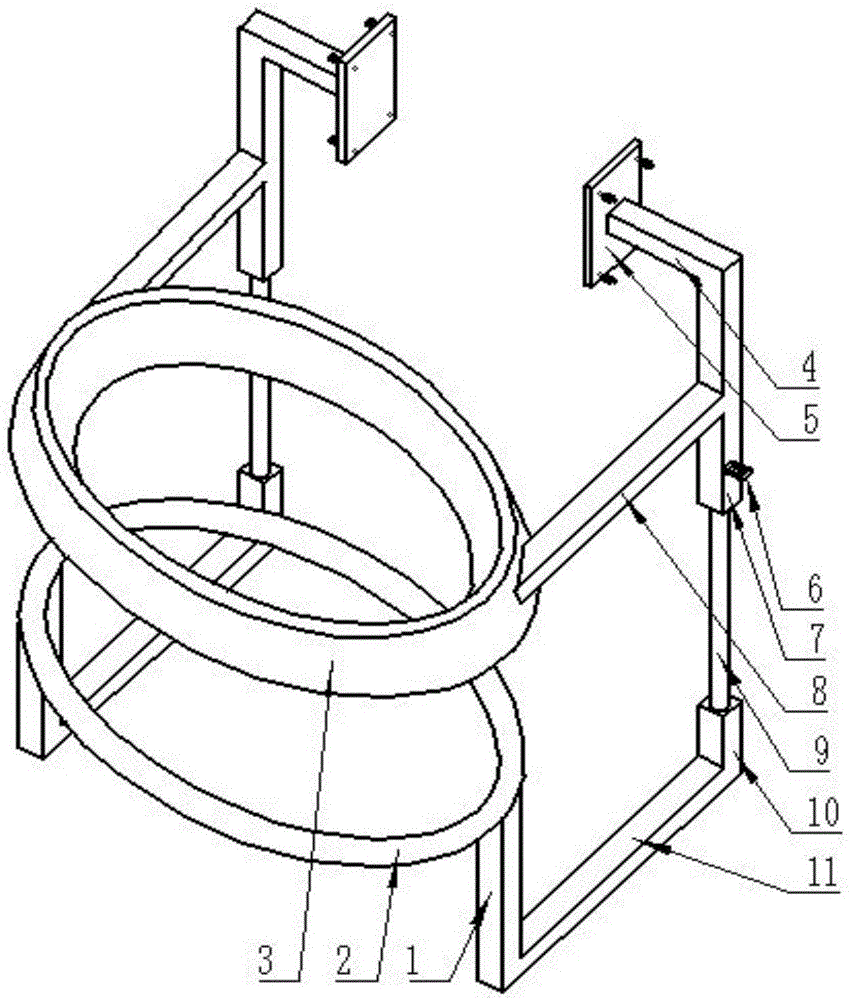

[0024] like figure 1 As shown, in order to overcome the defects of the prior art, the present invention provides a pocket clamping device that utilizes the bagging ring to move and clamp, including a first bracket 1, a fourth bracket 7, a fifth bracket 4, and a fixing plate 5 , clamping ring bracket 8, piston rod 9, third bracket 10 and second bracket 11; fixed plate 5 connects one end of the fifth bracket 4, and the other end of the fifth bracket 4 connects one end of the fourth bracket 7, and the fourth bracket The middle part of 7 is connected with one end of the clamping ring bracket 8, the other end of the clamping ring bracket 8 is connected with the clamping ring 3, the other end of the fourth bracket 7 is provided with a hydraulic cylinder, and the piston of the hydraulic cylinder is connected with one end of the piston rod 9, The other end of piston rod 9 connects an end of the third support 10, and the other end of the third support 10 connects an end of the second s...

Embodiment 2

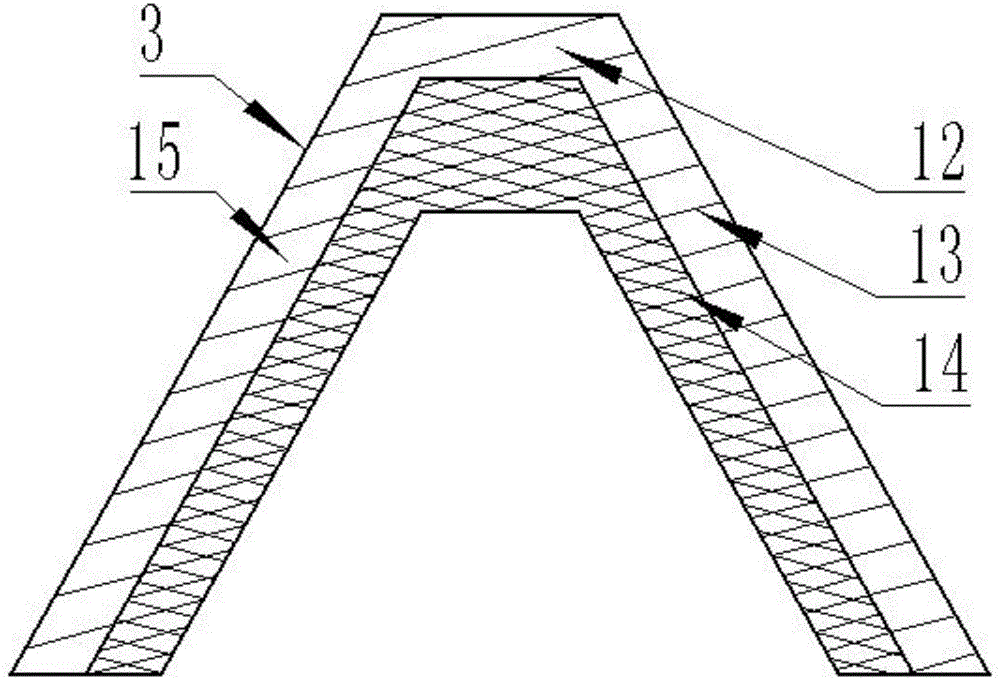

[0028] This embodiment is further improved on the basis of embodiment 1, as figure 1 , figure 2 As shown, the clamping ring 3 includes a transverse plate 12, an outer plate 13 and an inner plate 15, the transverse plate 12 is arranged on the upper part of the outer plate 13 and the upper part of the inner plate 15, and the angle between the outer plate 13 and the transverse plate 12 is equal to the inner The angle between the plate 15 and the transverse plate 12, the transverse plate 12, the outer plate 13 and the inner plate 15 form an annular accommodation chamber with an opening, the cross section of the annular accommodation chamber is an isosceles trapezoid, and the opening position of the annular accommodation chamber On the long base of an isosceles trapezoid. This setting can make the clamping ring 3 cooperate with the bagging ring 2 whose cross-sectional size is within a certain range, so that the versatility of the clamping ring 3 is better; at the same time, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com