Preparation method of aluminum-lithium alloy super-plastic fine-grain plate

A technology for aluminum-lithium alloys and plates, which is applied in the field of aluminum alloy thermal processing, can solve the problems of reduced grain refinement effect, coarse grains, and reduced dislocation density, and achieve fine grains, grain refinement, and suppression The effect of sheet cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

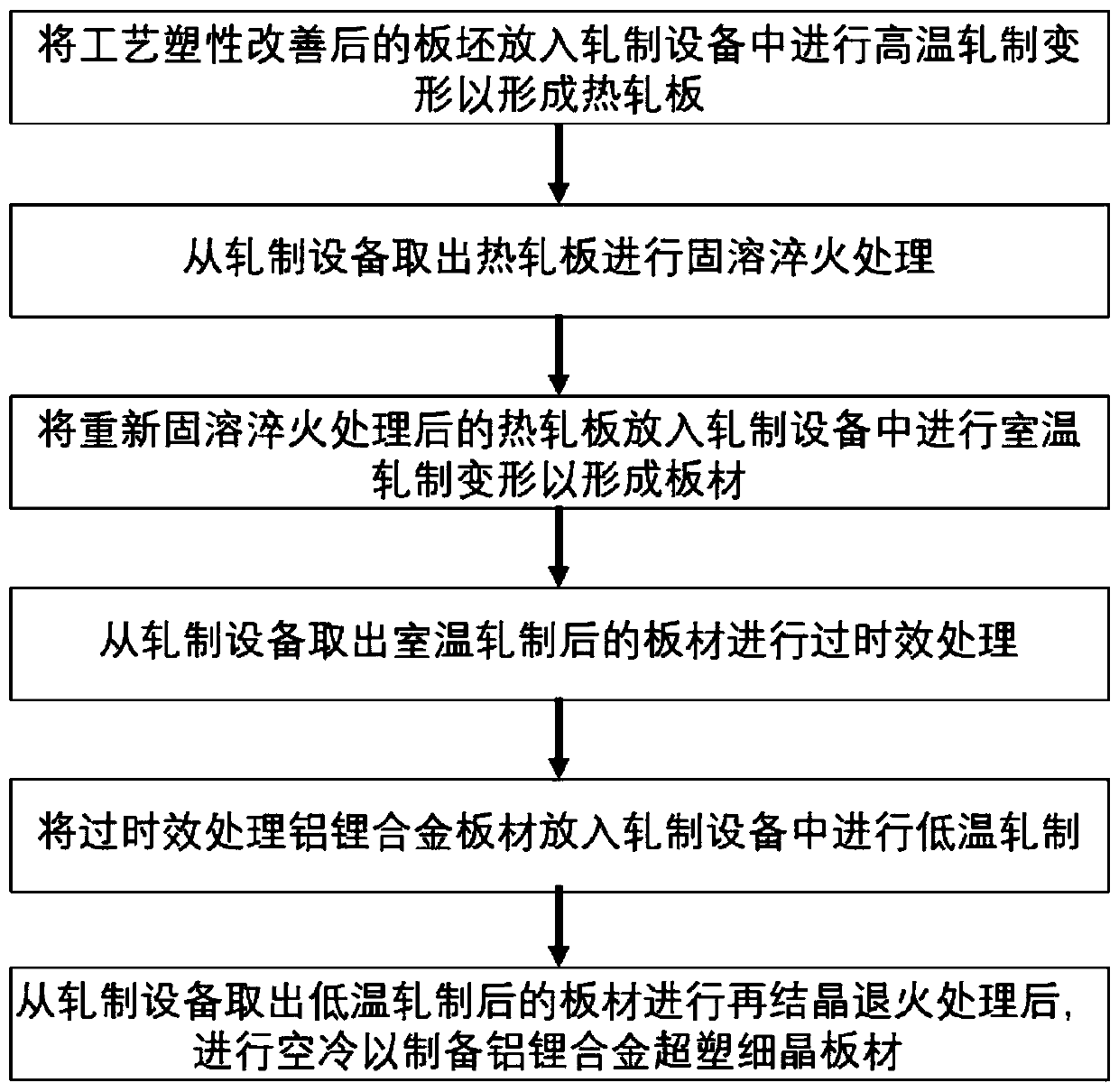

[0054] see figure 1 , the present invention provides a method for preparing an aluminum-lithium alloy superplastic fine-grained plate, the method comprising the following steps S110 to S160:

[0055] In step S110, the slab whose process plasticity has been improved by forging and pressing is put into a rolling equipment for high-temperature rolling deformation to form a hot-rolled slab. In this step, the rolling start temperature of the high-temperature rolling is 400-480° C., and the rolling deformation is 30%-40%.

[0056] Step S120, taking out the hot-rolled sheet from the rolling equipment to perform solution quenching treatment. In this step, the solution temperature is 450-510° C., and the solution time is 1-3 hours.

[0057] Step S130 , put the hot-rolled plate after the re-solution quenching treatment into the rolling equipment for rolling deformation at room temperature to form a plate. In this step, the total rolling deformation of room temperature rolling is 50%-...

Embodiment 1

[0072] Test material: spray-formed 2195 aluminum-lithium alloy billet.

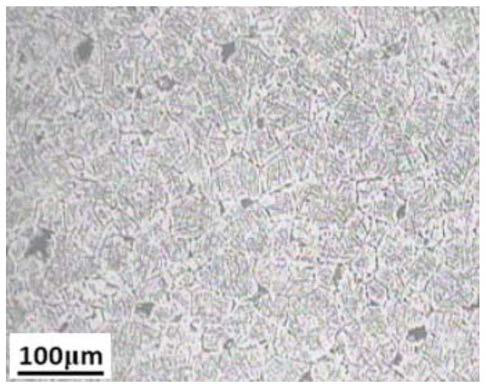

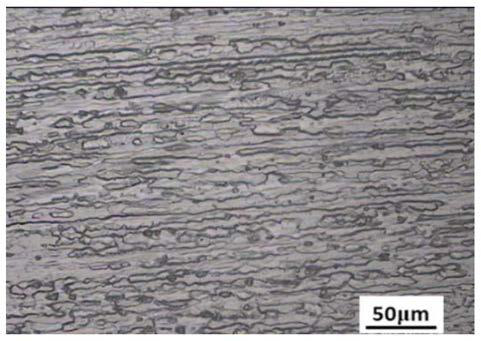

[0073] Experimental process: Extrusion densification, forging, solution treatment, high temperature hot rolling, solution treatment, room temperature rolling, solution treatment, overaging, low temperature rolling, and The process of combining crystallization and annealing to prepare 2195 aluminum-lithium alloy superplastic fine-grained plate, the specific implementation steps are as follows:

[0074] Step 1, removing the scale of the spray-formed aluminum-lithium alloy ingot to obtain a spray-formed aluminum-lithium alloy billet with a smooth surface, and cutting the billet into short rods of aluminum-lithium alloy with a diameter of 550mm and a length of 800-1200mm;

[0075] Step 2: Extrude and densify the spray-formed 2195 aluminum-lithium alloy ingot, the temperature of the extrusion cylinder is 430°C, the temperature of the mold is 400°C, the product speed is 0.2m / min, and the extrusion ratio is 9; ...

Embodiment 2

[0086] In step 2, the extrusion barrel temperature is 420-450°C, the mold temperature is 380-420°C, the product speed is 0.15-0.25m / min, the extrusion ratio is 8-10, and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com