A kind of isobornyl acrylamide containing phosphorus phenanthrene oxide, its preparation method and application

A technology of isobornyl acrylamide and isobornyl propyl acrylamide, which is applied in the field of isobornyl acrylamide phosphorus phenanthrene oxides, can solve the problem that it is difficult to take into account the mechanical properties of polyurethane foam and the flame retardant properties. To application requirements and other issues, to achieve the effect of significant flame retardant enhancement, high flame retardant performance, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

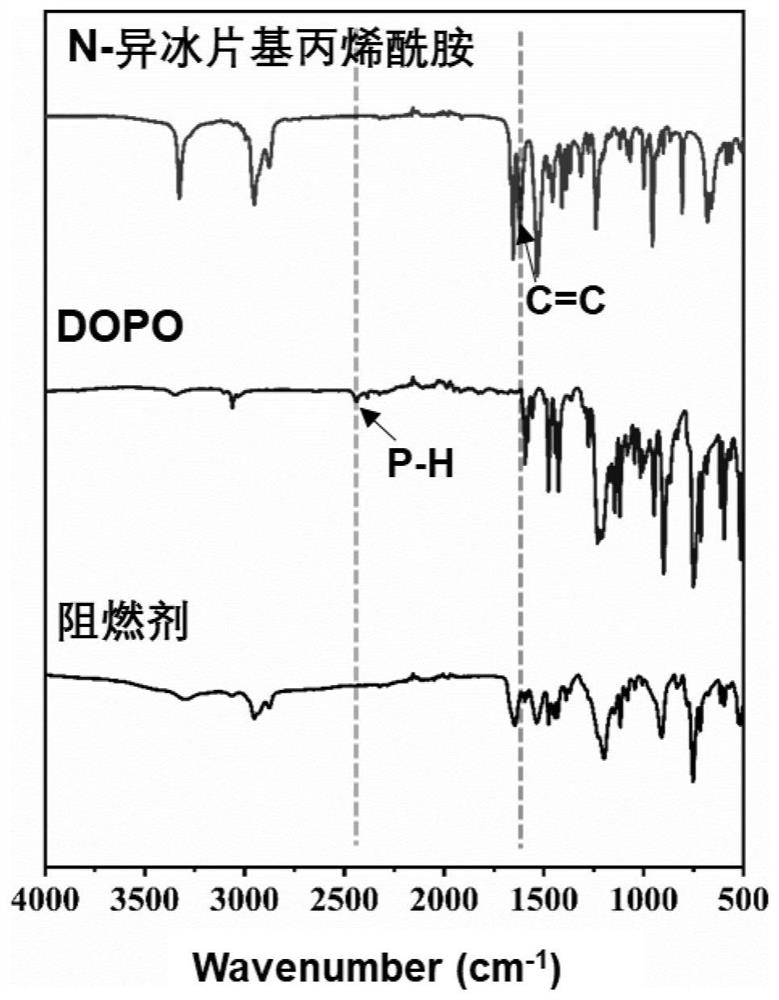

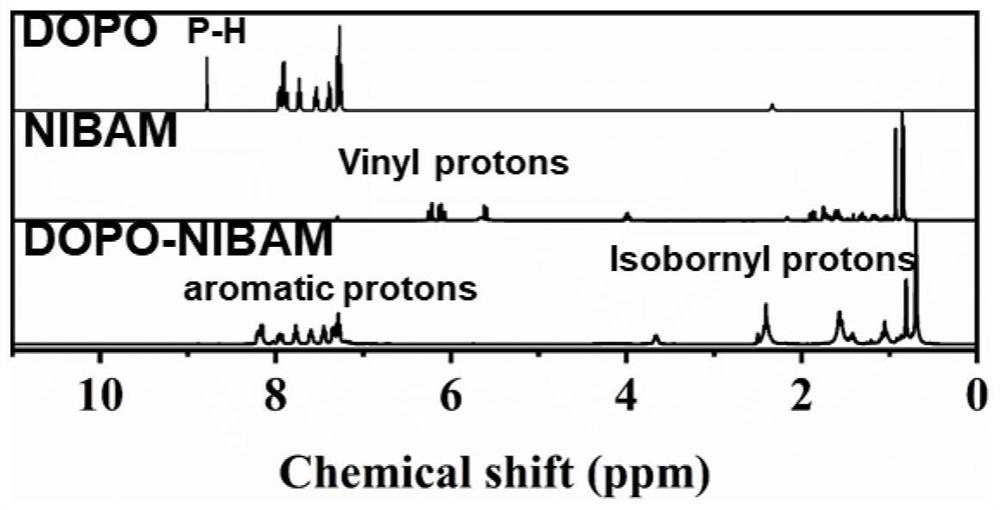

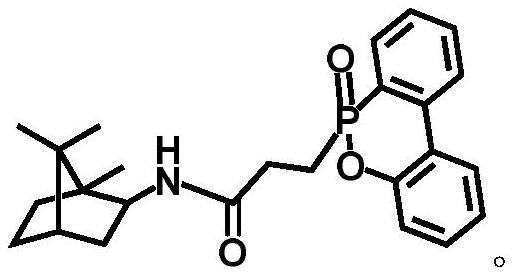

Embodiment 1

[0037] Weigh 6.19g of camphene, 1.33g of ferric chloride and 7.85ml of acrylonitrile, react at 120°C for 12h to obtain N-isobornyl acrylamide. Weigh 16.21g of DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) and heat it to 160°C to be in a molten state, then add 10.37g of N-isobornyl acrylamide and stir After 24 hours of reaction, the reaction was completed, and after extraction and recrystallization, the isobornyl acrylamide-containing phosphaphenanthrene oxide was obtained. Weigh 100 parts by weight of polyether polyol (ZS4110, Jiangsu Zhongshan Chemical Co., Ltd.), 3 parts by weight of foam stabilizer modified silicone oil (OFX-0193, Suzhou Spiai New Material Co., Ltd.), 1.2 parts by weight of water, 0.1 parts by weight Parts of N,N-dimethylcyclohexylamine (DMCHA), 2.54 parts by weight of isobornyl acrylamide containing phosphaphenanthrene oxide and mixed uniformly to prepare component A. Weigh 100 parts by weight of polyisocyanate (PM-200, Wanhua Chemical Group C...

Embodiment 2

[0056] Weigh 6.19g of camphene, 1.33g of ferric chloride and 7.85ml of acrylonitrile, react at 120°C for 12h to obtain N-isobornyl acrylamide. Weigh 16.21g of DOPO and heat it to 160°C to be in a molten state, then add 10.37g of N-isobornyl acrylamide, stir and react for 24 hours, after the reaction is completed, after extraction and recrystallization, the isobornyl acrylamide-containing phenanthrene oxide is obtained . Weigh 100 parts by weight of polyether polyol (ZS4110, Jiangsu Zhongshan Chemical Co., Ltd.), 3 parts by weight of foam stabilizer modified silicone oil (OFX-0193, Suzhou Spiai New Material Co., Ltd.), 1.2 parts by weight of water, 0.1 parts by weight Parts of N,N-dimethylcyclohexylamine (DMCHA), 1.0 parts by weight of isobornyl acrylamide containing phosphaphenanthrene oxide and mixed uniformly to prepare component A. Weigh 100 parts by weight of polyisocyanate (PM-200, Wanhua Chemical Group Co., Ltd.), and name it as component B. A component and B component...

Embodiment 3

[0059] Weigh 6.19g of camphene, 1.33g of ferric chloride and 7.85ml of acrylonitrile, react at 120°C for 12h to obtain N-isobornyl acrylamide. Weigh 16.21g of DOPO and heat it to 160°C to be in a molten state, then add 10.37g of N-isobornyl acrylamide, stir and react for 24 hours, after the reaction is completed, after extraction and recrystallization, the isobornyl acrylamide-containing phenanthrene oxide is obtained . Weigh 100 parts by weight of polyether polyol (ZS4110, Jiangsu Zhongshan Chemical Co., Ltd.), 3 parts by weight of foam stabilizer modified silicone oil (OFX-0193, Suzhou Spiai New Material Co., Ltd.), 1.2 parts by weight of water, 0.1 parts by weight Parts of N,N-dimethylcyclohexylamine (DMCHA), 4.0 parts by weight of isobornyl acrylamide containing phosphaphenanthrene oxide and mixed uniformly to prepare component A. Weigh 100 parts by weight of polyisocyanate (PM-200, Wanhua Chemical Group Co., Ltd.), and name it as component B. A component and B component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com