Patents

Literature

42results about How to "Sufficient flame retardancy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame retardant resin composition and flame-retardant injection-molding

In order to provide a resin composition containing a lactic acid resin, and a molded article obtained from this resin composition which impart flame retardance to the resin composition and suppress a reduction in the molecular weight, use is made of a flame-retardant resin composition which contains a resin composition of which the major component is a lactic acid resin, and a surface-treated metallic hydroxide, wherein the surface-treated metallic hydroxide is added by 50-150 parts by mass per 100 parts by mass of the lactic acid resin.

Owner:SONY CORP

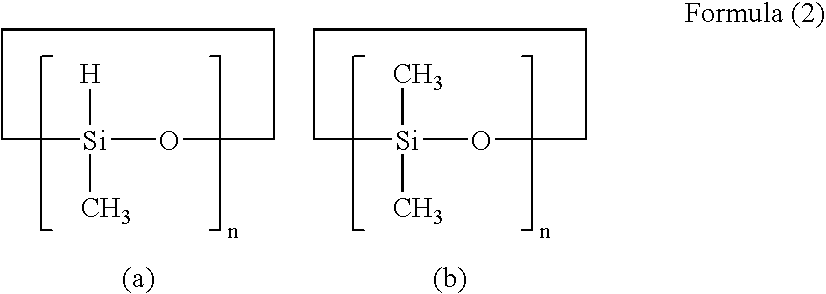

Non-crosslinked flame-retardant resin compsition, and an insulated wire and a wire harness using the same

InactiveUS20070048524A1Sufficient flame retardancySolve the lack of flexibilityPlastic/resin/waxes insulatorsSpecial tyresAdditive ingredientPliability

To provide a non-crosslinked flame-retardant resin composition possessing sufficient flame retardancy, mechanical properties, flexibility and workability, and also delivering excellent heat resistance over a long period of time as it is hard to be molten when used under high temperature environment and its material is not deteriorated even if used in contact with a vinyl chloride resin material and the like, and an insulated wire and a wiring harness using the same. The composition includes (A) a non-crosslinked base resin which contains a propylene resin containing 50 wt % or more of propylene monomer and a thermoplastic resin of which a melting point is 180° C. or more, (B) a metallic hydrate, (C) a hindered phenolic antioxidant, (D) a sulfurous antioxidant, and (E) a metallic oxide. Polymethylpentene, an imidazole compound and an oxide of zinc are preferably utilized as the thermoplastic resin, the ingredients (D) and (E), respectively. The composition is used as an insulated covering material for a non-halogenous insulated wire, which is used in a wire bundle of the wiring harness.

Owner:AUTONETWORKS TECH LTD +2

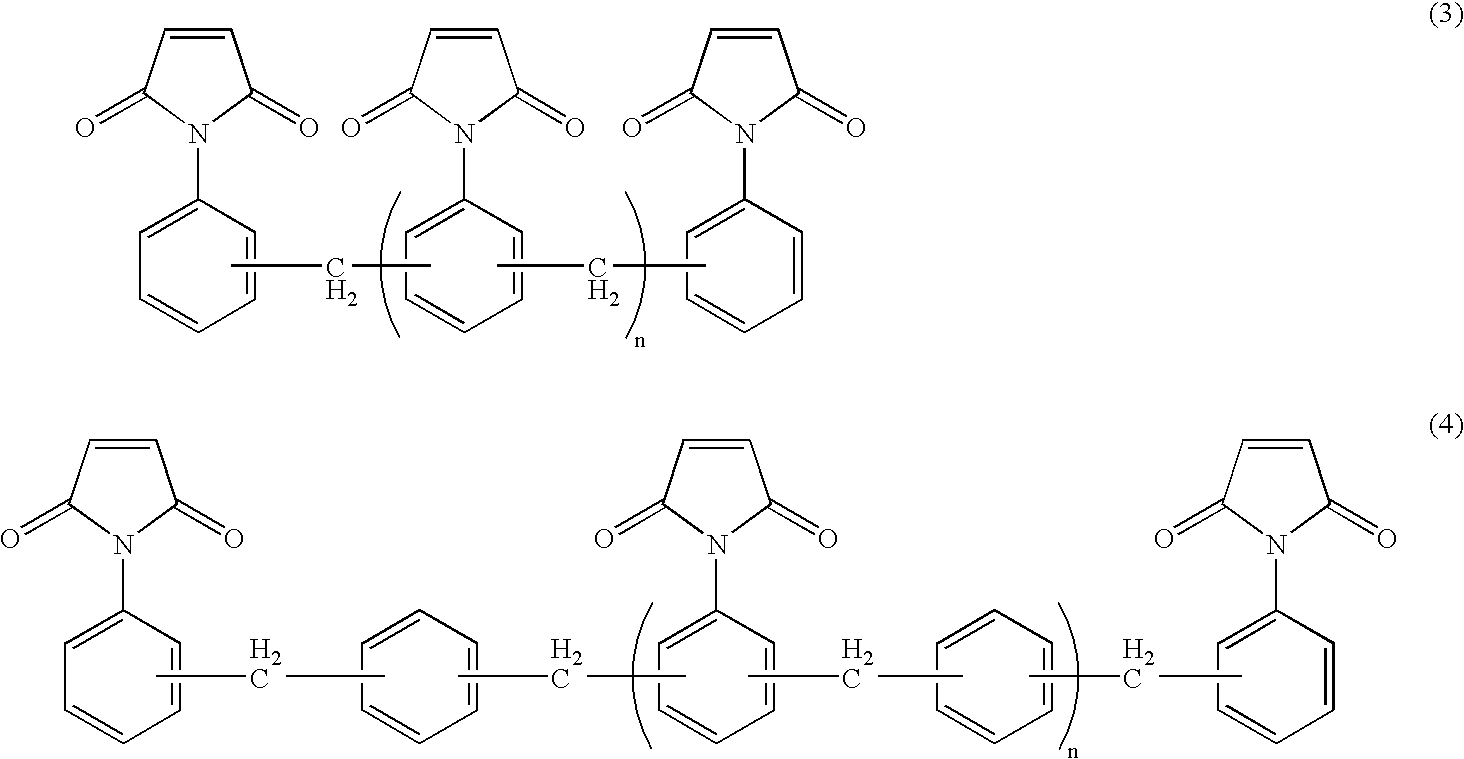

Resin composition, prepreg and laminate using the composition

InactiveUS20050095434A1Improve flame retardant performanceImprove moisture resistanceSynthetic resin layered productsElectrical equipmentEpoxyImide

The present invention is to provide a laminate which is halogen-free, has sufficient flame retardancy even when a thickness is not more than 0.2 mm, and has sufficient humidity resistance and hygroscopic solder heat resistance. A resin composition comprising: (A) a compound having at least two or more maleimide groups; (B) a phenolic resin; and (C) an epoxy resin; wherein at least one of said (B) or (C) has a naphthalene ring; the total weight of the naphthalene ring when calculated using the OH equivalent and epoxy equivalent of (B) and (C) respectively is not less than 20 weight % to the total weight of (A), (B) and (C) components; and the total sum of the content ratio of the (A) component and that of the naphthalene ring is not less than 65 weight % to the total weight of the (A), (B) and (C) components, and a prepreg and laminate obtained from the same.

Owner:MITSUI CHEM INC

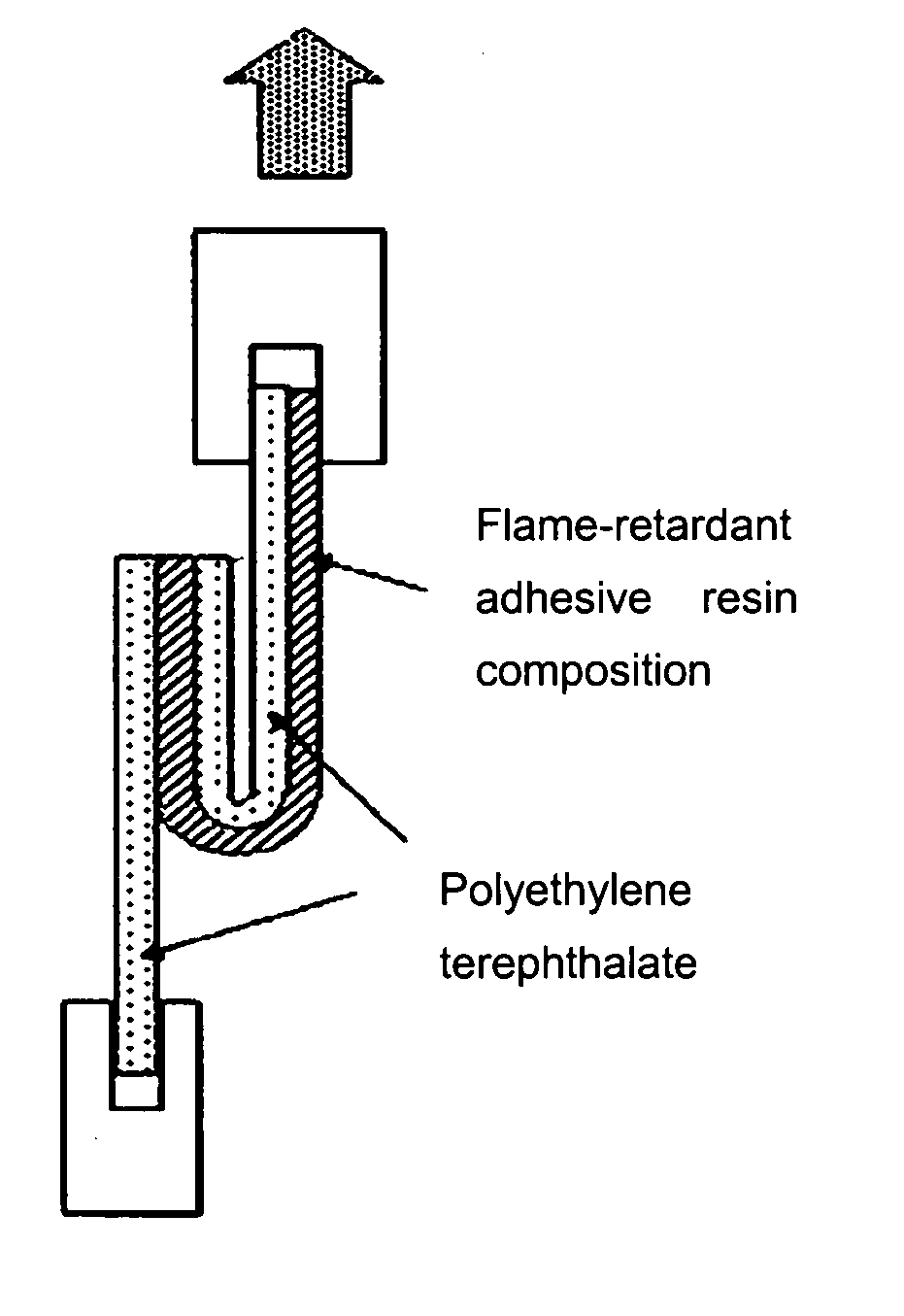

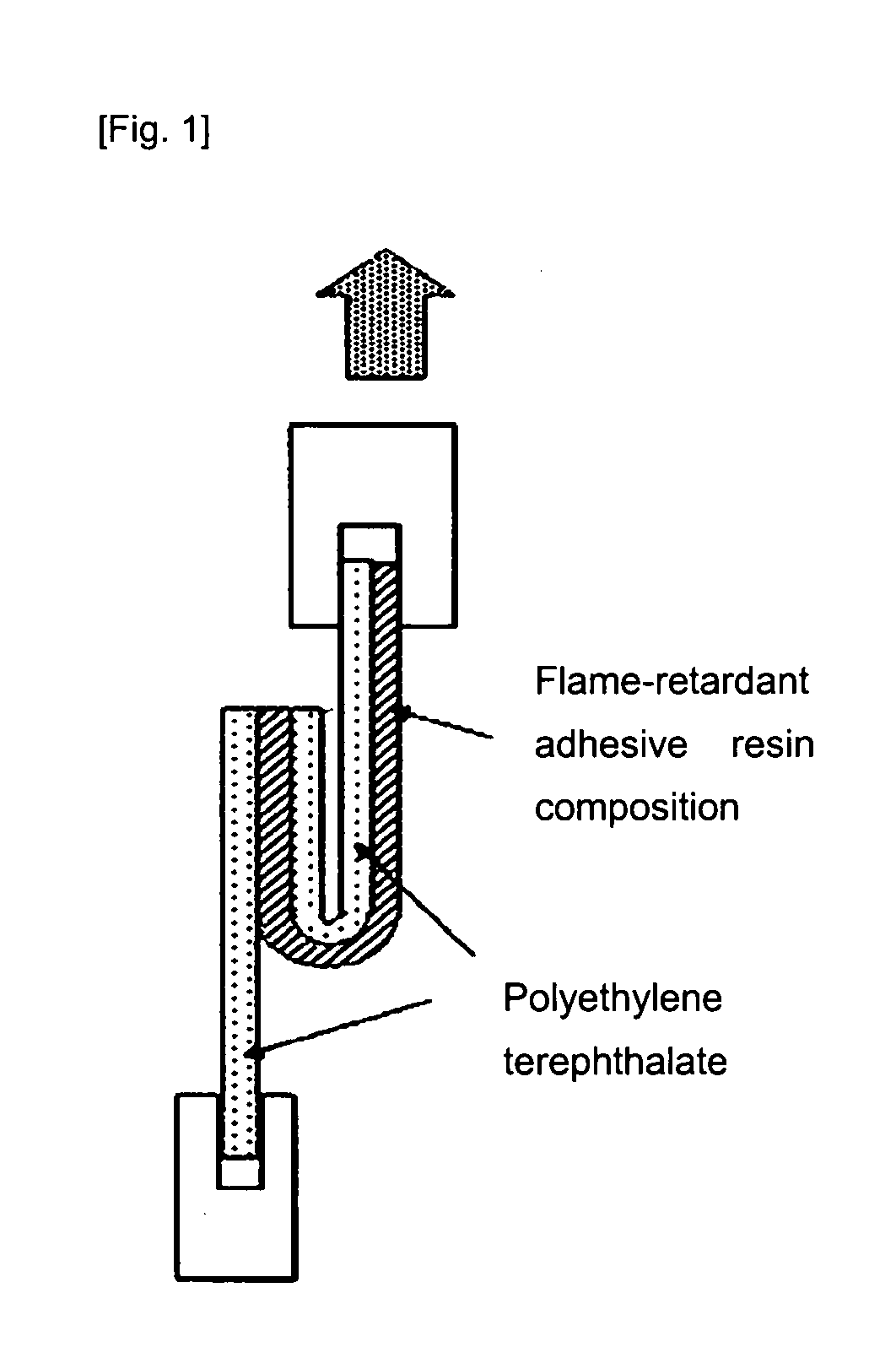

Flame-retardant adhesive composition and laminated film

InactiveUS20110177330A1Improve securityImprove flame retardant performancePlastic/resin/waxes insulatorsAdhesive articlesHalogenFoaming agent

As a novel laminated film which uses no halogen series compound and is capable of conferring in a flame-retardant adhesive composition comprising a phosphorus series compound mixed therein an even better flame-retardancy, a laminated film is proposed, provided with a resin layer on at least one face of a flame-retardant adhesive composition layer comprising a flame-retardant adhesive composition containing a thermoset-type adhesive resin composition (A), a phosphorus series compound (B) with a melting temperature of 170° C. or higher and a foaming agent (C) in an unfoamed state.

Owner:MITSUBISHI PLASTICS INC

Flame retardant resin composition and flame-retardant injection-molding

In order to provide a resin composition containing a lactic acid resin, and a molded article obtained from this resin composition which impart flame retardance to the resin composition and suppress a reduction in the molecular weight, use is made of a flame-retardant resin composition which contains a resin composition of which the major component is a lactic acid resin, and a surface-treated metallic hydroxide, wherein the surface-treated metallic hydroxide is added by 50-150 parts by mass per 100 parts by mass of the lactic acid resin.

Owner:SONY CORP

Flame-retardant resin composition and flame-retardant resin-molded article

InactiveUS20070249756A1High dimensional accuracyLarge specific surface areaSimple Organic CompoundsVolume average

A flame-retardant resin composition comprising a biodegradable resin and flame-retardant particles having a volume average particle diameter in the range of 1 nm to 500 nm dispersed in the biodegradable resin, wherein the flame-retardant particles contain a metal hydrate and have a coating layer containing an organic compound or a polysilicone, and a flame-retardant resin-molded article comprising a biodegradable resin and flame-retardant particles having a volume average particle diameter of 1 nm to 500 nm dispersed in the biodegradable resin, wherein the flame-retardant particles comprise a metal hydrate, and the flame-retardant resin-molded article has a flame retardancy of HB or higher according to the UL-94 test.

Owner:FUJIFILM BUSINESS INNOVATION CORP

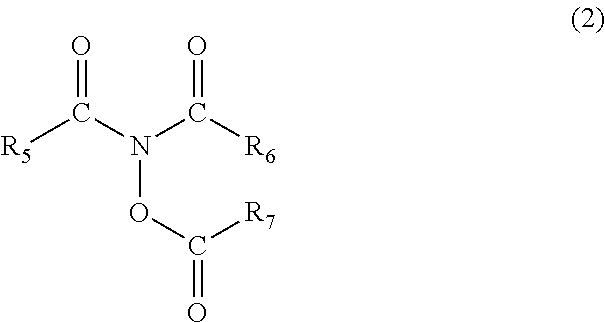

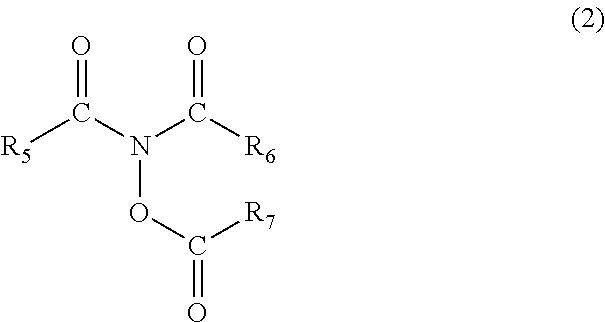

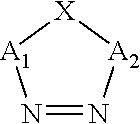

Nonaqueous secondary battery and flame retardant for use in the same

InactiveUS20130004839A1Sufficient flame retardancyImprove featuresLi-accumulatorsOrganic electrolytesArylHydrogen atom

A nonaqueous secondary battery comprising: a positive electrode; a negative electrode; and a nonaqueous electrolyte solution, wherein the nonaqueous electrolyte solution contains: a cyclic nitrogen-containing compound represented by the general formula (1):wherein X represents an optionally branched divalent group derived from a chain saturated hydrocarbon and having 1 to 5 carbon atoms, ═C═CH2, ═C═O, ═C═S═O, ═O or ═S, and A1 and A2 may be the same or different and each represent an optionally substituted methylene group, ═C═O or ═SO2; and an amine derivative represented by the general formula (2):wherein R5 to R7 may be the same or different and each represent a hydrogen atom, or an optionally substituted lower alkyl group, lower alkenyl group, lower alkoxy group, lower alkylcarbonyloxy group, lower alkylcarbonyl group, lower cycloalkyl group or aryl group.

Owner:SHARP KK

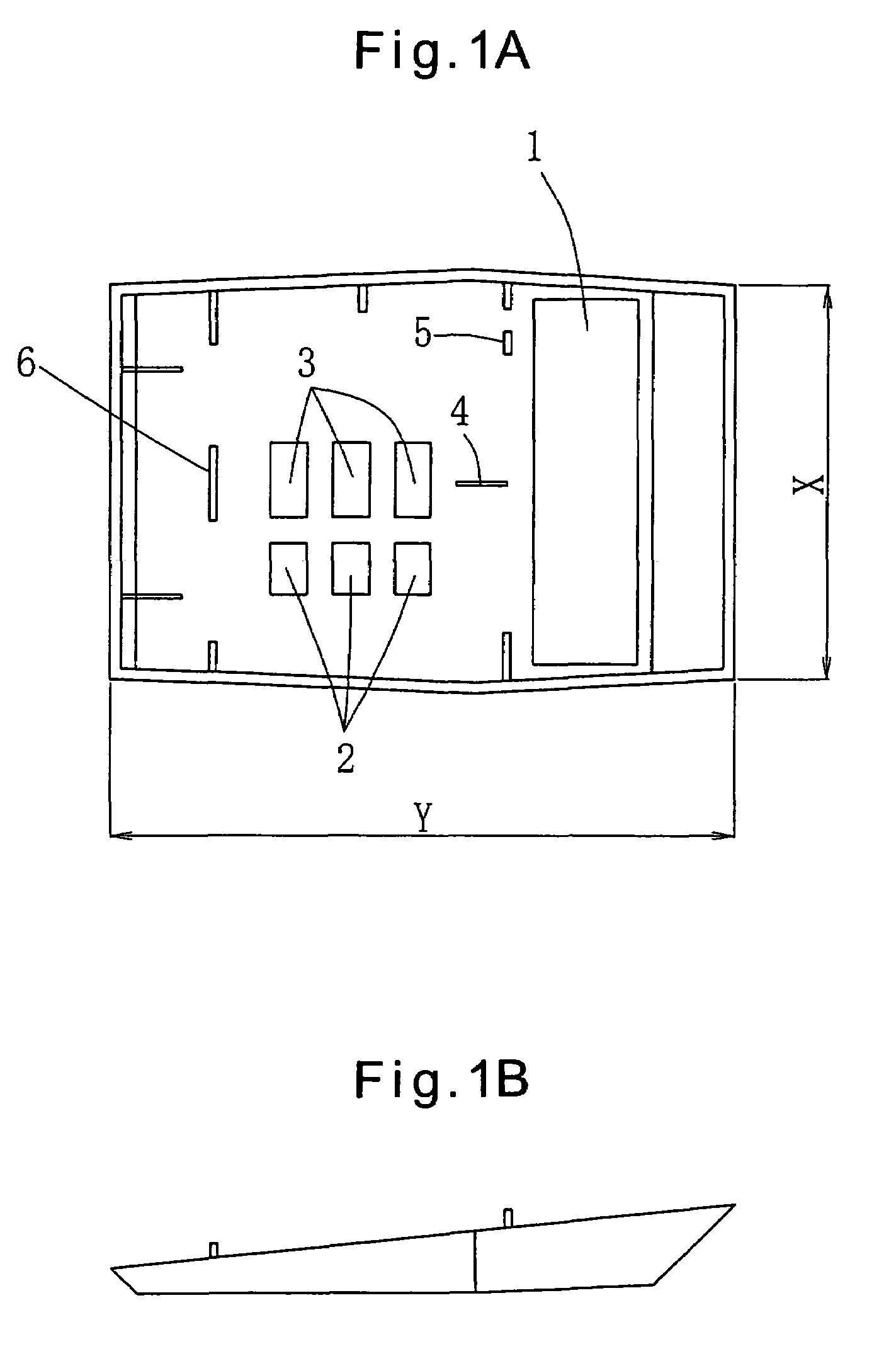

Non-halogen flame resistant base material and carpet for vehicle or airplane use

InactiveCN1637063AExcellent stability over timeGood heat resistanceCleaning apparatus for vehicle exteriorsAmmonium polyphosphateEmulsion

The present invention provides a non-halogen flame-retardant base material that has flame retardancy, excellent processability and heat resistance, and excellent stability over time of the base material without using a halogen flame retardant. The non-halogen flame-retardant base material of the present invention contains: the following (A) and (B), relative to 100 parts by weight (converted to solid content) (A) vinyl cyanide-acrylic acid copolymer water-based latex, (B ) is 20-500 parts by weight (B-1) of at least one non-halogen flame retardant selected from ammonium polyphosphates, phosphoric acid esters and water-soluble ammonium phosphates and / or 20-500 parts by weight (B-2 ) non-halogen metal hydrate [However, when using (B-1) and (B-2) together, (B-1)+(B-2) = 20 to 500 parts by weight], by The base material is coated on the inner surface of the carpet and dried to obtain a vehicle or aircraft carpet.

Owner:ETEC

Thermoplastic resin and formed product

InactiveUS7217757B2Sufficient flame retardancyHigh impact strengthSpecial tyresPolymer scienceCompressive strength

To provide a thermoplastic resin composition capable of affording a molded article which has excellent flame retardancy and compressive strength, which has good dimensional accuracy and which has good appearance. A thermoplastic resin composition including (A) 0.5 to 99.9 mass % of an aromatic polycarbonate-polyorganosiloxane copolymer terminated with an aromatic compound, (B) 0 to 99.5 mass % of an aromatic polycarbonate terminated with an aromatic compound, (C) 0.1 to 5 mass % of fine silica, and (D) 0 to 2 mass % of a polytetrafluoroethylene resin, and a molded article thereof, which are compounded together.

Owner:IDEMITSU KOSAN CO LTD

Non-Halogenous Insulated Wire and a Wiring Harness

InactiveUS20090025978A1Sufficient flame retardancyExcellent heat resistanceInsulated cablesInsulatorsElectrical conductorMelting point

A non-halogenous insulated wire possessing sufficient flame retardancy and excellent heat resistance, wear resistance and flexibility, and a wiring harness including the wire. The wire includes a conductor, an inside coat of one or more layers and an outermost coat, wherein the outermost coat is in the range of 10 to 100 μm in thickness and is made from a resin composition including an olefin resin with a melting point of 180° C. or more and / or an olefin resin having a —Si(X1)(X2)(X3) group, by 20 wt % or more, and at least one of the layers of the inside coat is made from a resin composition including (A) an olefin resin with a melting point of 180° C. or more by 50 to 5 part weight, (B) an olefin resin by 50 to 95 part weight, and (C) a metallic hydrate by 30 to 250 part weight.

Owner:AUTONETWORKS TECH LTD +2

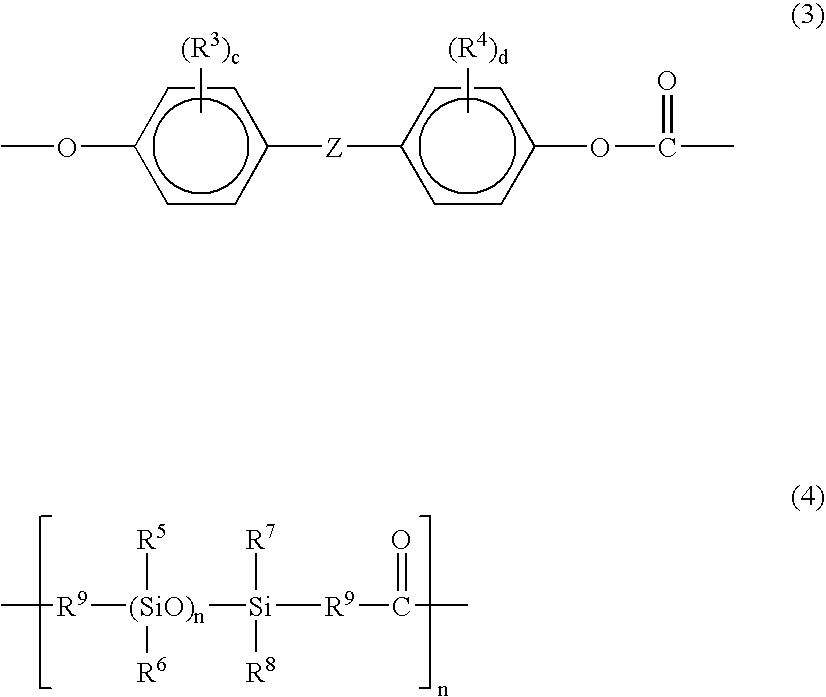

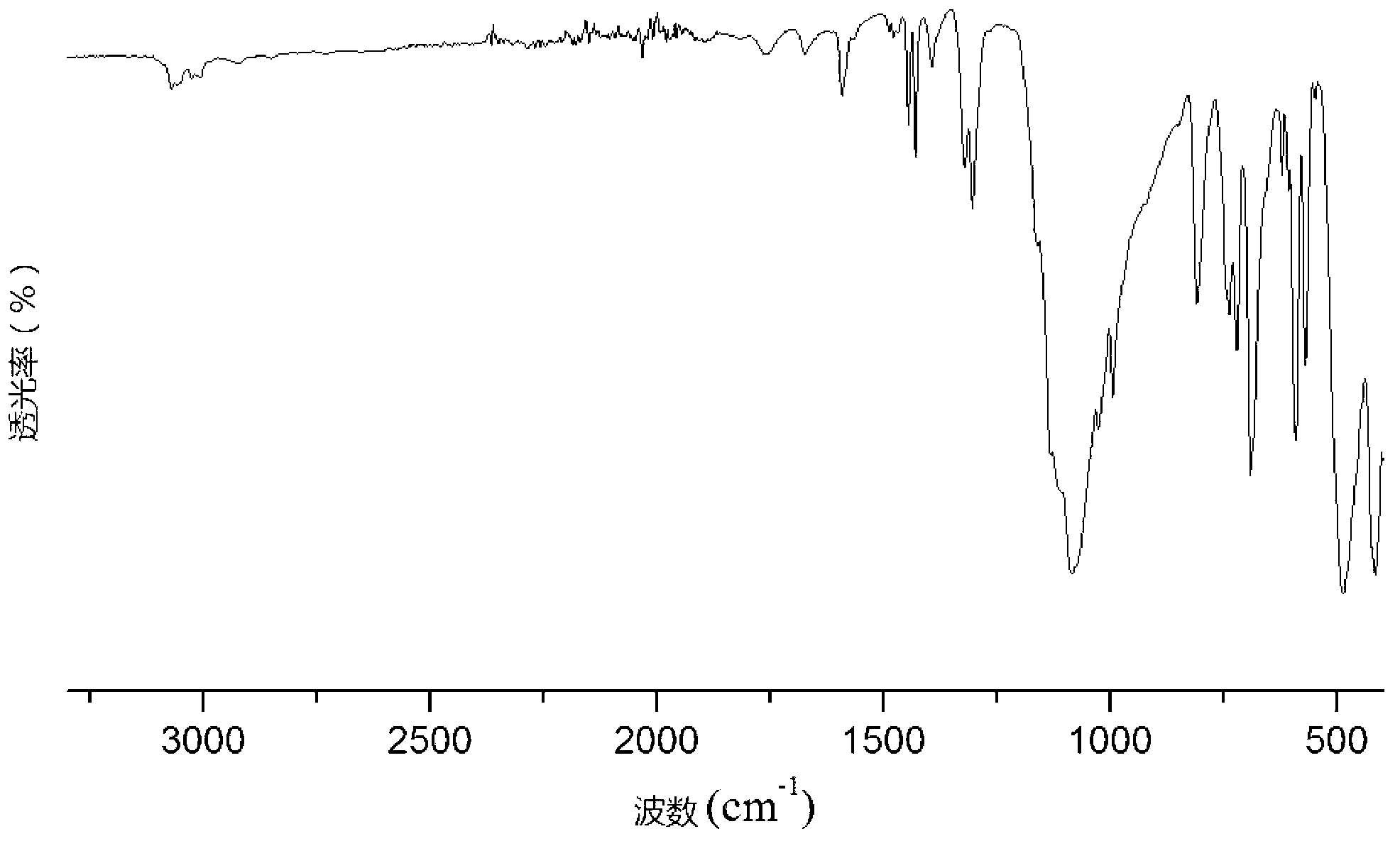

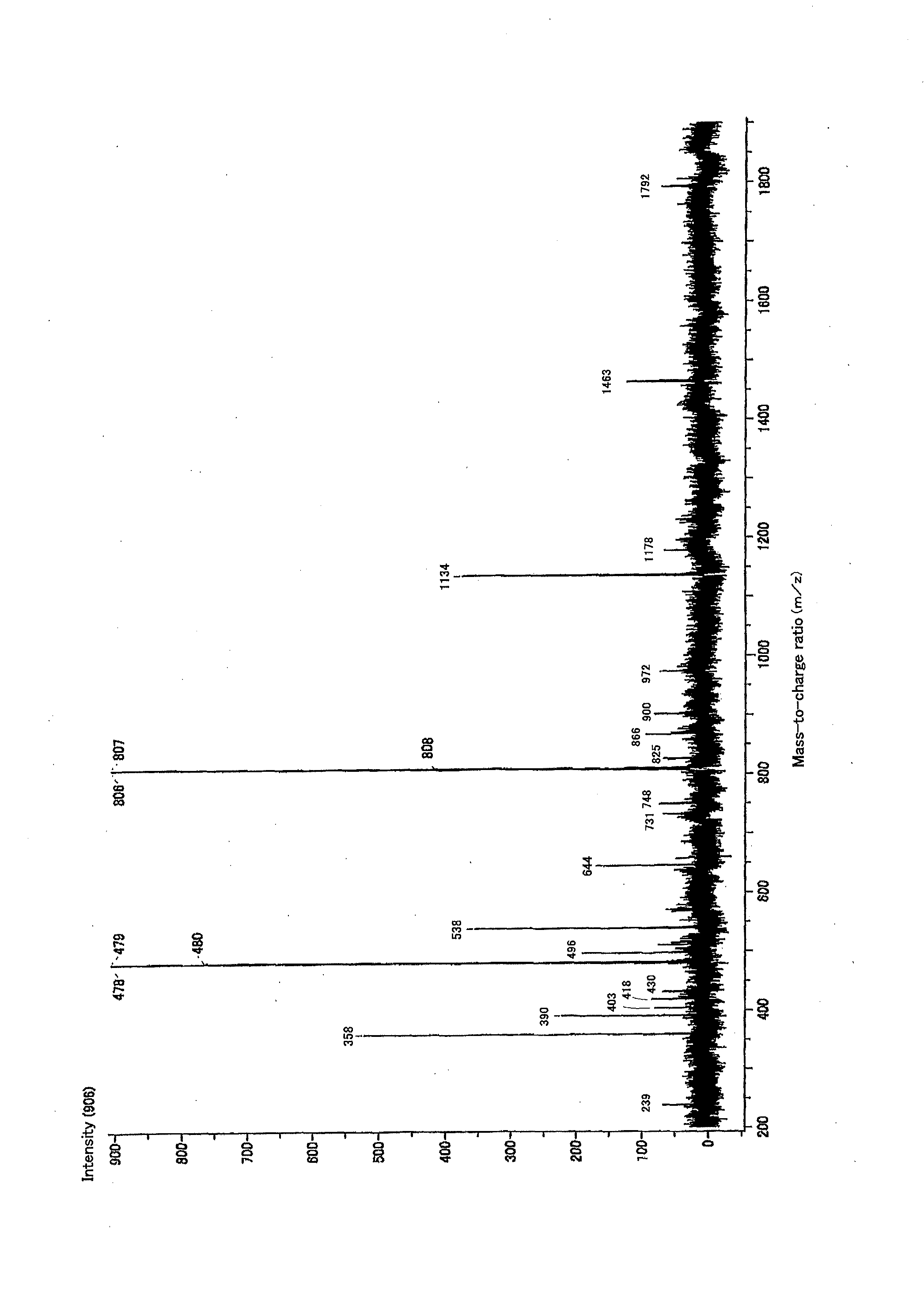

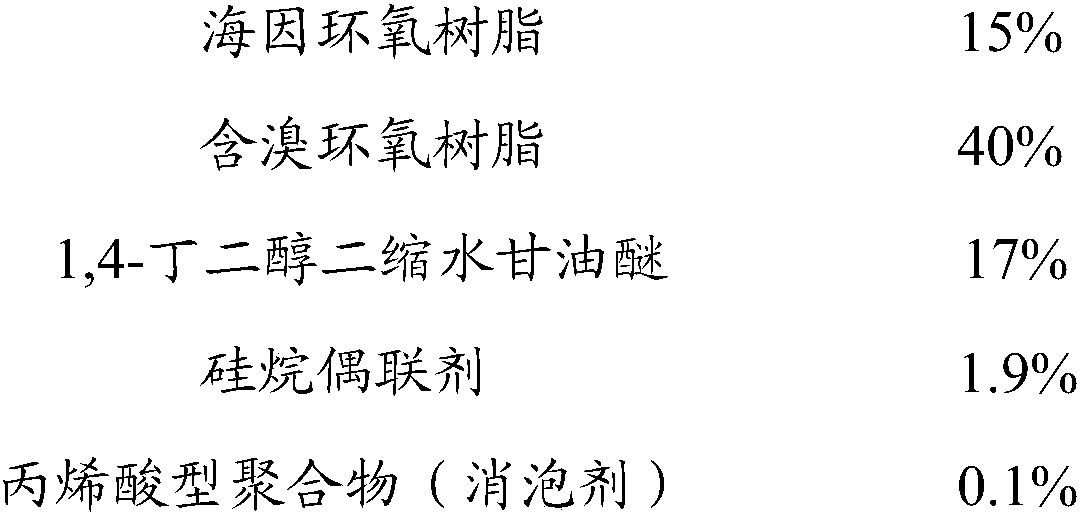

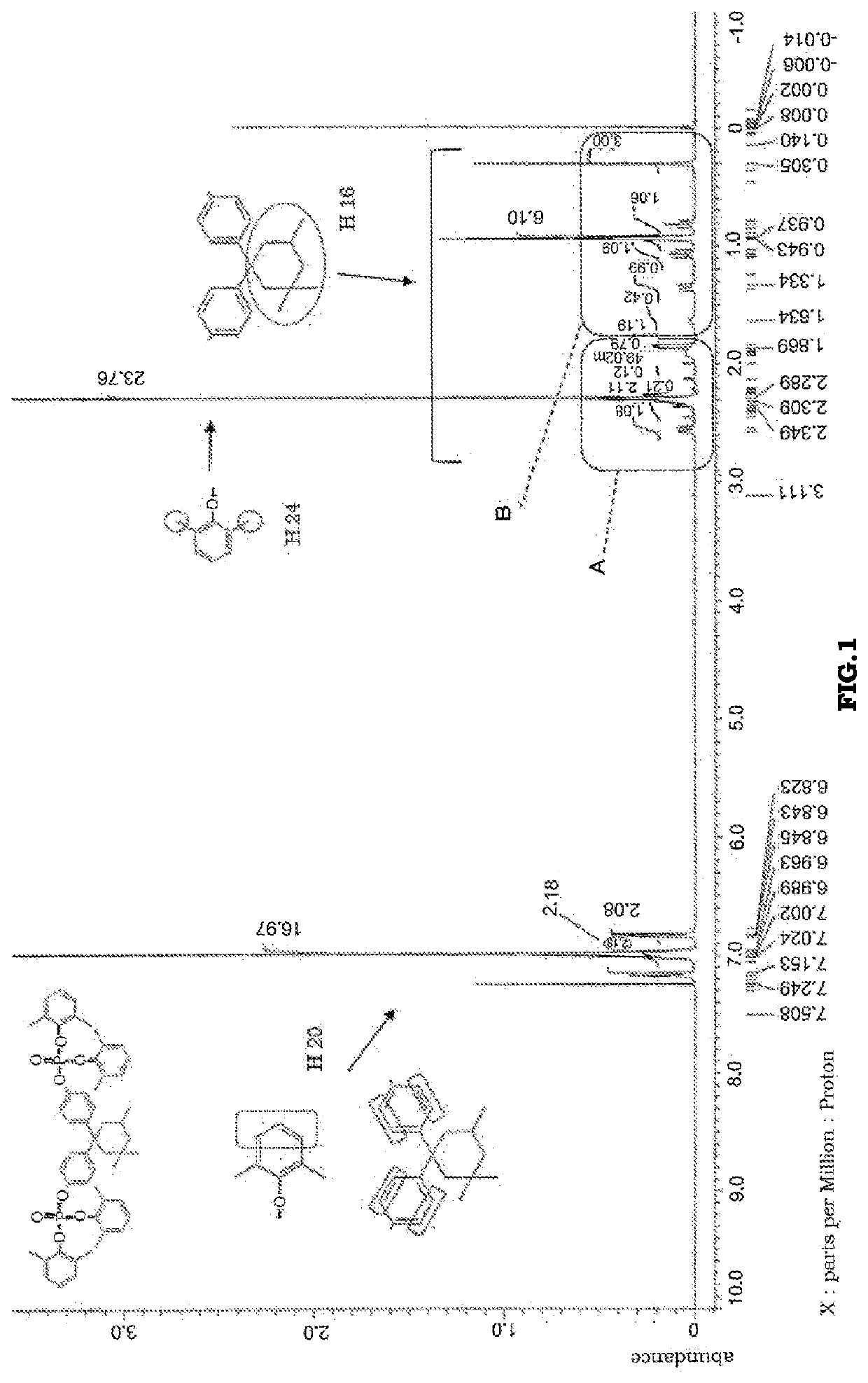

Cage-type diphenyl sulfone-based oligomeric silsesquioxane and preparation method for same

ActiveCN103193817AGood dielectricImprove mechanical propertiesSilicon organic compoundsPolymer scienceSilsesquioxane

The invention relates to a cage-type diphenyl sulfone-based oligomeric silsesquioxane and a preparation method for the same, and belongs to the technical field of nanometre materials. The cage-type diphenyl sulfone-based oligomeric silsesquioxane disclosed by the invention contains 1, 2, 3, 4, 5, 6, 7 or 8 diphenyl sulfone groups. The cage-type diphenyl sulfone-based oligomeric silsesquioxane disclosed by the invention has the characteristics of being moderate and stable in reaction conditions, good in repeatability, high in productivity, short in cycle and the like, and is suitable for expanded production; and the obtained product is added in a polymer by means of blending or copolymerization and the like, and capable of improving the various performances of dielectricity, mechanical property, flame retardance, high-temperature resistance and the like of the polymer.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Graft copolymer, production method therefor, resin composition, and molded article

ActiveUS20130281586A1Improve impact resistanceSufficient flame retardancyGroup 5/15 element organic compoundsToluenePolymer chemistry

Disclosed are a method of producing a graft copolymer, comprising polymerizing a vinyl monomer (B) containing a polyfunctional vinyl monomer (b1) in the presence of a polyorganosiloxane rubber (A) comprising more than 20% by mass of a toluene-insoluble matter, wherein a mass percentage of the polyfunctional vinyl monomer (b1) is 11 to 19% by mass based on 100% by mass of a total amount of the polyorganosiloxane rubber (A) and the vinyl monomer (B); a graft copolymer obtained by the method; a resin composition being prepared by blending the graft copolymer with a resin and having high impact resistance and heat resistance and sufficient flame retardancy; and a molded article obtained by molding the resin composition.

Owner:MITSUBISHI CHEM CORP

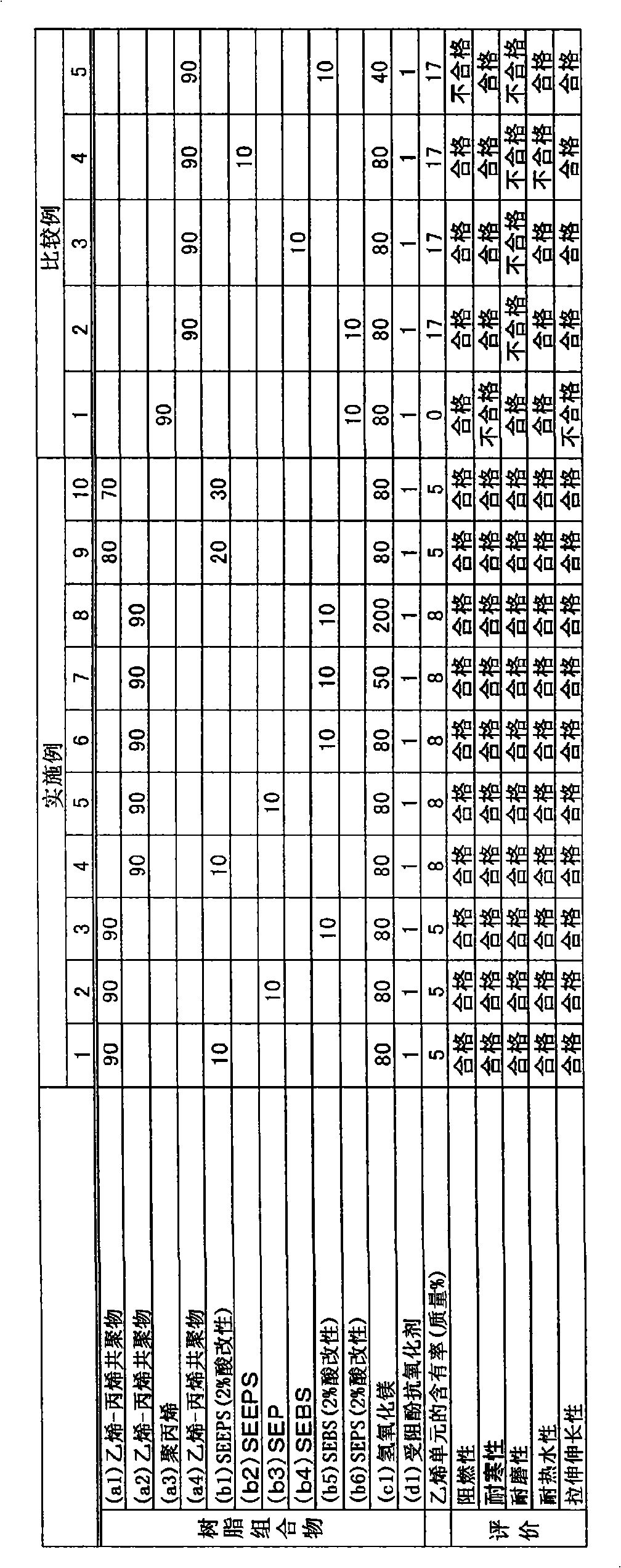

Flame-retardant resin composition, insulating electric wire and wire harness

InactiveCN101558117AImprove cold resistanceImprove wear resistanceInsulated cablesInsulatorsConductive materialsNatural mineral

A flame-retardant resin composition which is inexpensive and is excellent in cold resistance, wear resistance and hot water resistance; and an insulating electric wire and a wire harness both utilizing the composition. Specifically disclosed is a flame-retardant resin composition which comprises a propylene polymer containing an ethylene unit in an amount of 1 to 15 wt% and magnesium hydroxide produced by using a natural mineral as a raw material. The composition preferably contains magnesium hydroxide in an amount of 50 to 200 parts by weight relative to 100 parts by weight of the polymer component in the composition. Further, the composition preferably contains a styrene-based thermoplastic elastomer. The propylene polymer preferably has a Charpy impact value of 3 to 8 KJ / m at -20 DEG C. An insulating electric wire can be produced by coating the outer region of a conductive material with the flame-retardant resin composition. A wire harness can be produced by using the insulating electric wire.

Owner:AUTONETWORKS TECH LTD +2

Elongated article with good flexibility and high flame retardancy

ActiveUS10669412B2Reduction processability and mechanical and elastic propertySufficient flame retardancyPlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneElastomer

The invention relates to elongated articles and polymer compositions used for preparing the elongated articles. The elongated articles comprise an inner structure / one or more elements including a static / moving current medium or communication medium; and a halogen-free polymer composition surrounding the element(s). The polymer composition includes a linear very low density polyethylene (VLDPE) composition and one or more polyolefin-elastomers. In addition, the polymer composition includes a flame retardant filler.

Owner:LEONI KABEL GMBH

Nonaqueous secondary battery and flame retardant for use in the same

InactiveUS9130245B2Sufficient flame retardancyImprove featuresOrganic electrolyte cellsLi-accumulatorsArylHydrogen atom

A nonaqueous secondary battery comprising: a positive electrode; a negative electrode; and a nonaqueous electrolyte solution, wherein the nonaqueous electrolyte solution contains: a cyclic nitrogen-containing compound represented by the general formula (1):wherein X represents an optionally branched divalent group derived from a chain saturated hydrocarbon and having 1 to 5 carbon atoms, ═C═CH2, ═C═O, ═C═S═O, ═O or ═S, and A1 and A2 may be the same or different and each represent an optionally substituted methylene group, ═C═O or ═SO2; and an amine derivative represented by the general formula (2):wherein R5 to R7 may be the same or different and each represent a hydrogen atom, or an optionally substituted lower alkyl group, lower alkenyl group, lower alkoxy group, lower alkylcarbonyloxy group, lower alkylcarbonyl group, lower cycloalkyl group or aryl group.

Owner:SHARP KK

Non-halogenous insulated wire and a wiring harness

InactiveUS7560647B2Sufficient flame retardancyImprove heat resistancePlastic/resin/waxes insulatorsInsulated cablesElectrical conductorHeat resistance

A non-halogenous insulated wire [possessing sufficient flame retardancy and excellent heat resistance, wear resistance and flexibility, ]and a wiring harness including the wire. The wire includes a conductor, an inside coat of one or more layers and an outermost coat, wherein the outermost coat is in the range of 10 to 100 μm in thickness and is made from a resin composition including an olefin resin with a melting point of 180 ° C. or more and / or an olefin resin having a —Si(XI) (X 2) (X 3) group, by 20 wt% or more, and at least one of the layers of the inside coat is made from a resin composition including (A) an olefin resin with a melting point of 180 ° C. or more by 50-5 to part weight, (B) an olefin resin by 50 to 95 part weight, and (C) a metallic hydrate by 30 to 250 part weight.

Owner:AUTONETWORKS TECH LTD +2

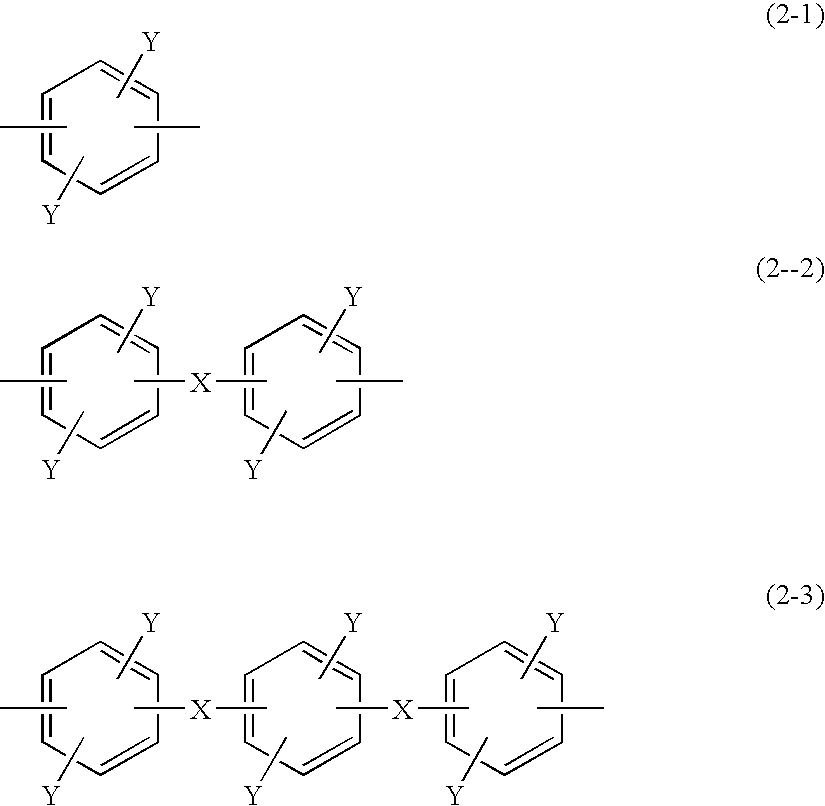

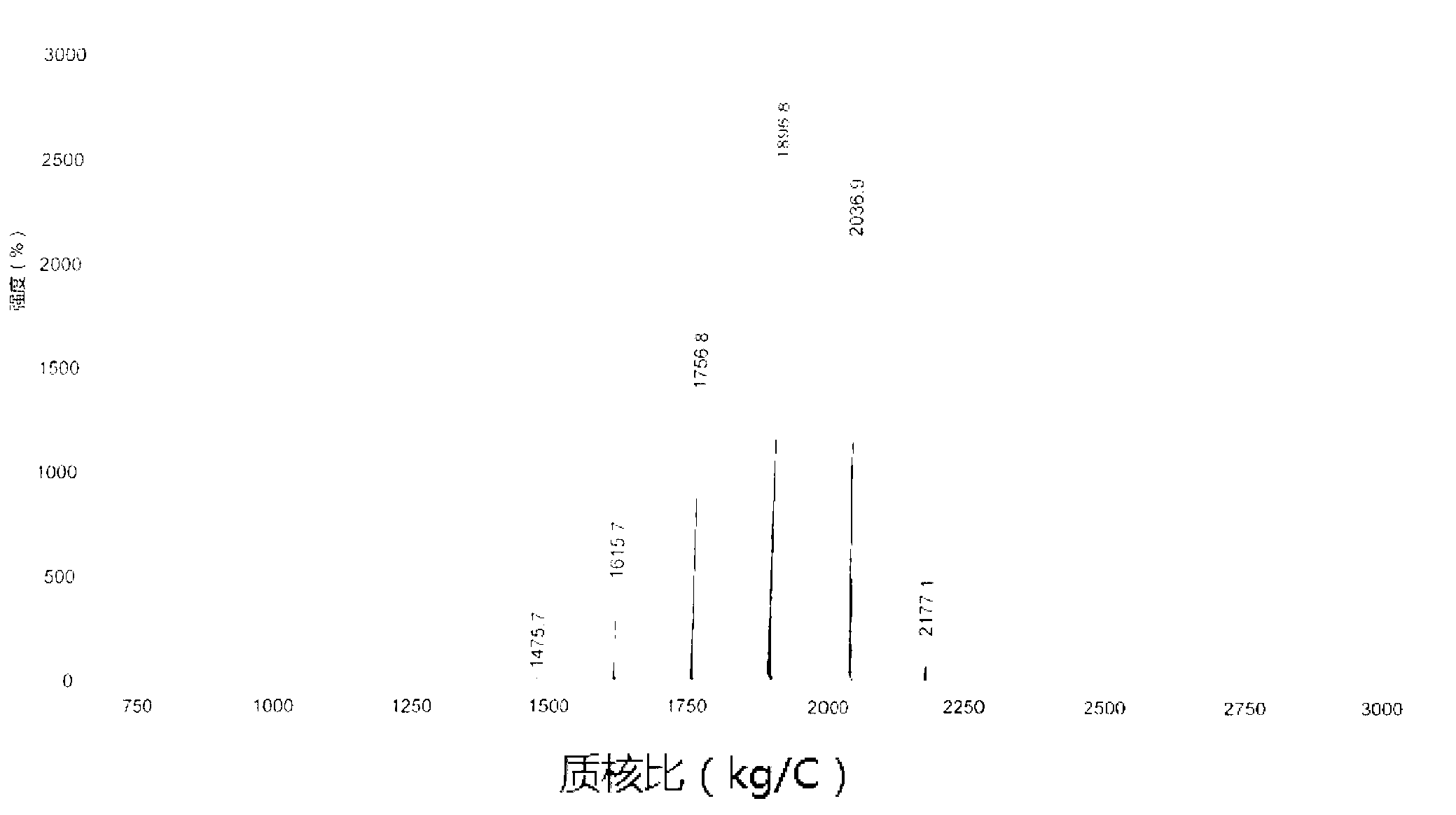

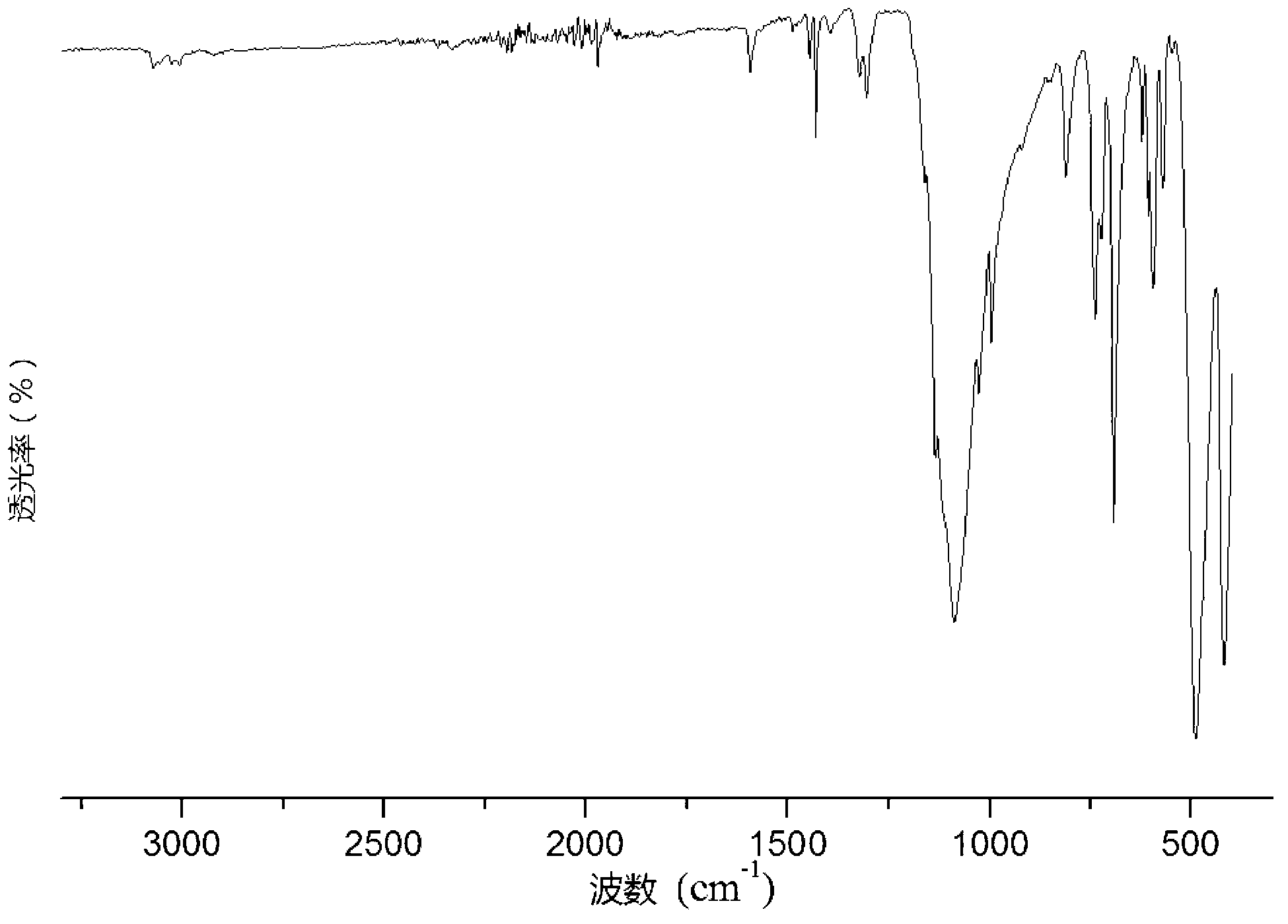

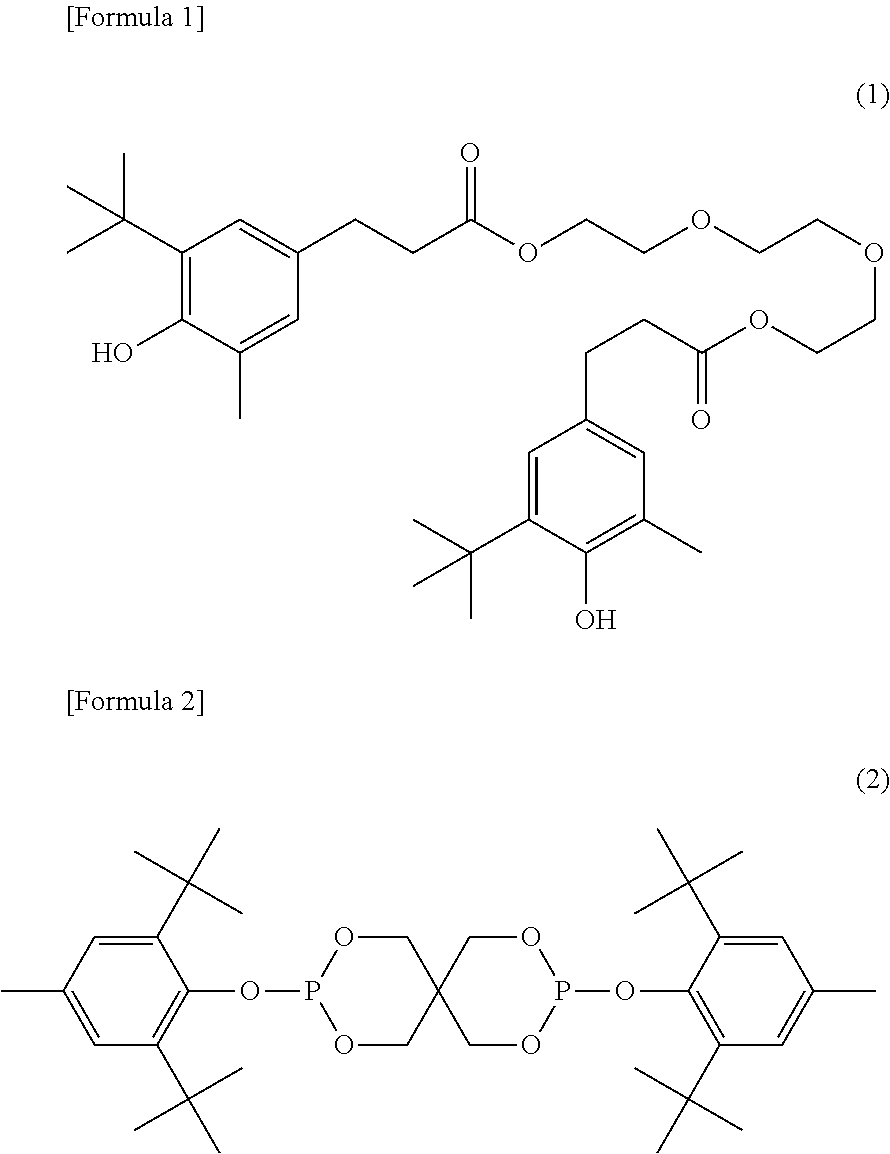

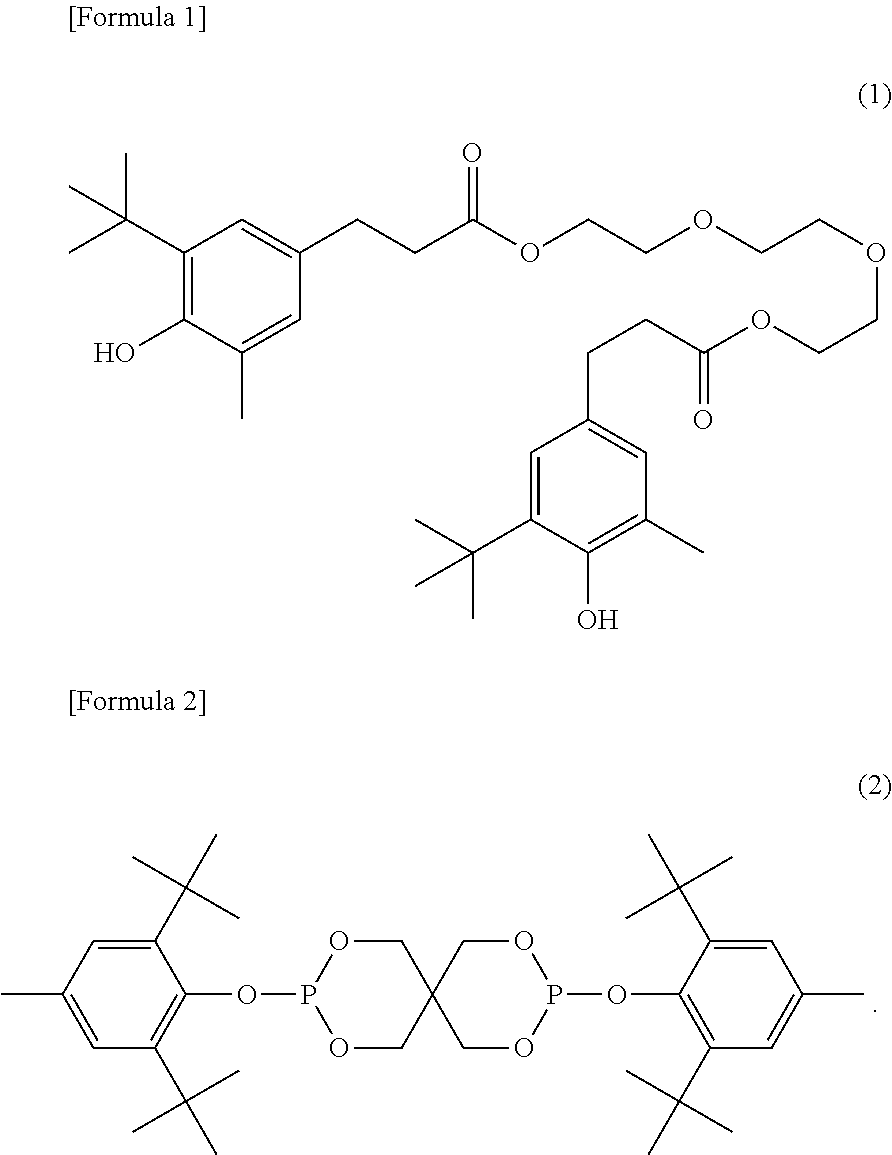

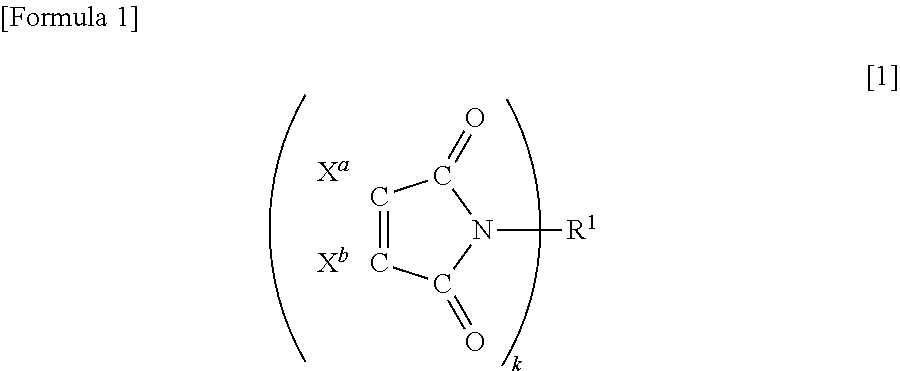

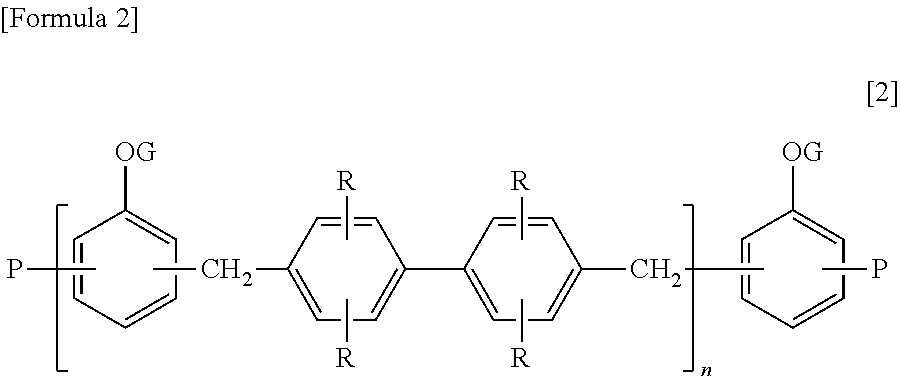

Resin composition, and prepreg and laminate using same

InactiveUS20130260155A1High TgLow thermal expansionSynthetic resin layered productsElectrical equipmentEpoxyThermal dilatation

A resin composition having high Tg (high heat resistance), low thermal expansion, and excellent flame retardancy, and being advantageous for promoting halogen-free, and having excellent adhesiveness with Cu, a prepreg obtained by impregnating it into substrate, and a composite and a laminate obtained from them. Specifically provided are a modified polyimide resin composition containing (A) a polymaleimide compound of formula [1], (B) epoxy resin having at least two glycidyl groups in the molecule of formula [2], and (c) phenolic compound having at least two OH groups in the molecule, and a prepreg obtained by impregnating the composition into the substrate, and a composite and a laminate obtained from the prepreg.

Owner:AIR WATER INC

Flame retardant-containing nonaqueous secondary battery

InactiveUS8420266B2Sufficient flame retardancyAvoid excessive impactOrganic electrolyte cellsLi-accumulatorsFire retardantElectrolyte

Owner:SHARP KK

Nonaqueous secondary battery and flame retardant for the same

InactiveUS8592081B2Stable cycle characteristicSufficient flame retardancyOrganic chemistryOrganic compound preparationArylHalogen

Owner:SHARP KK

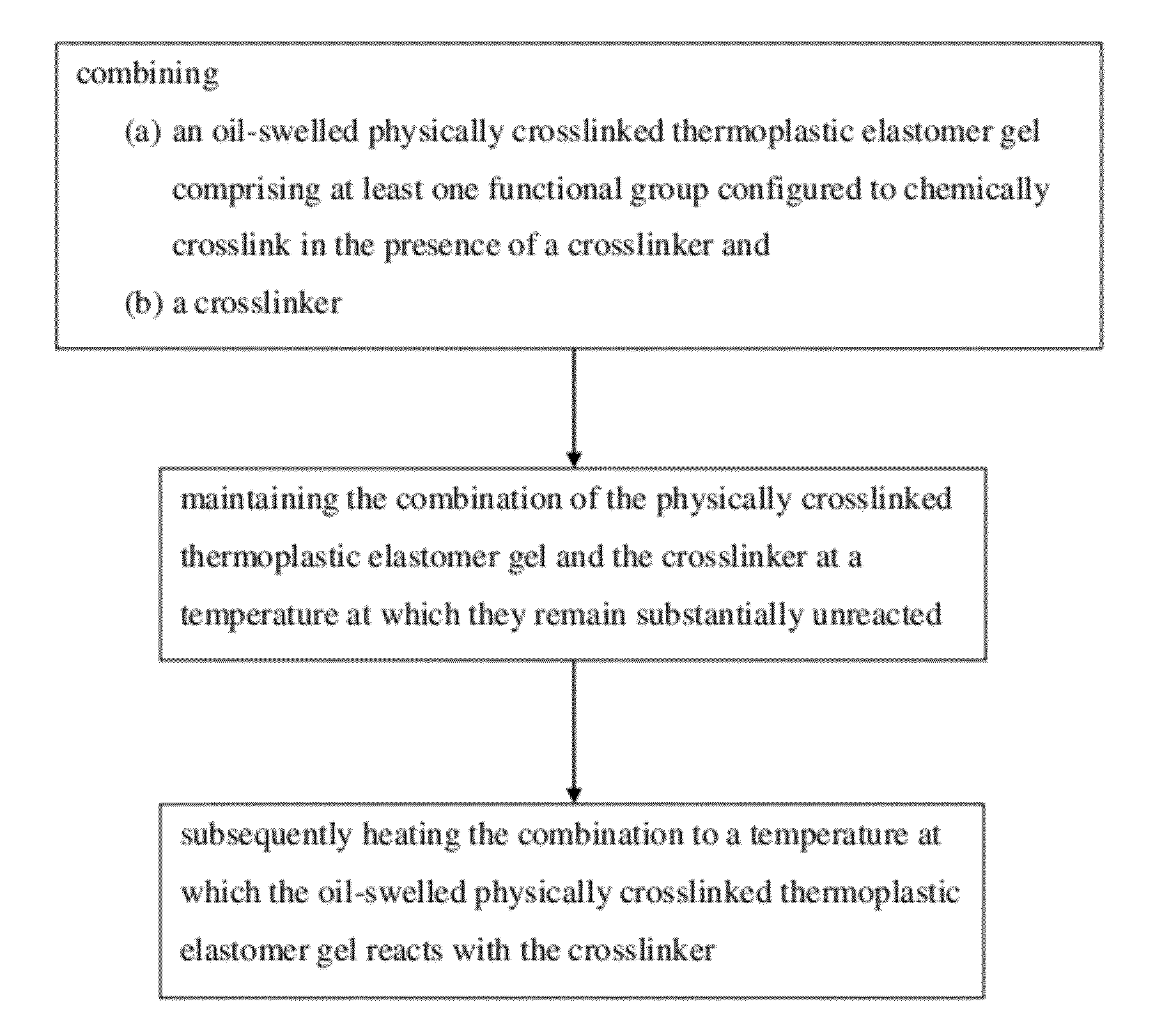

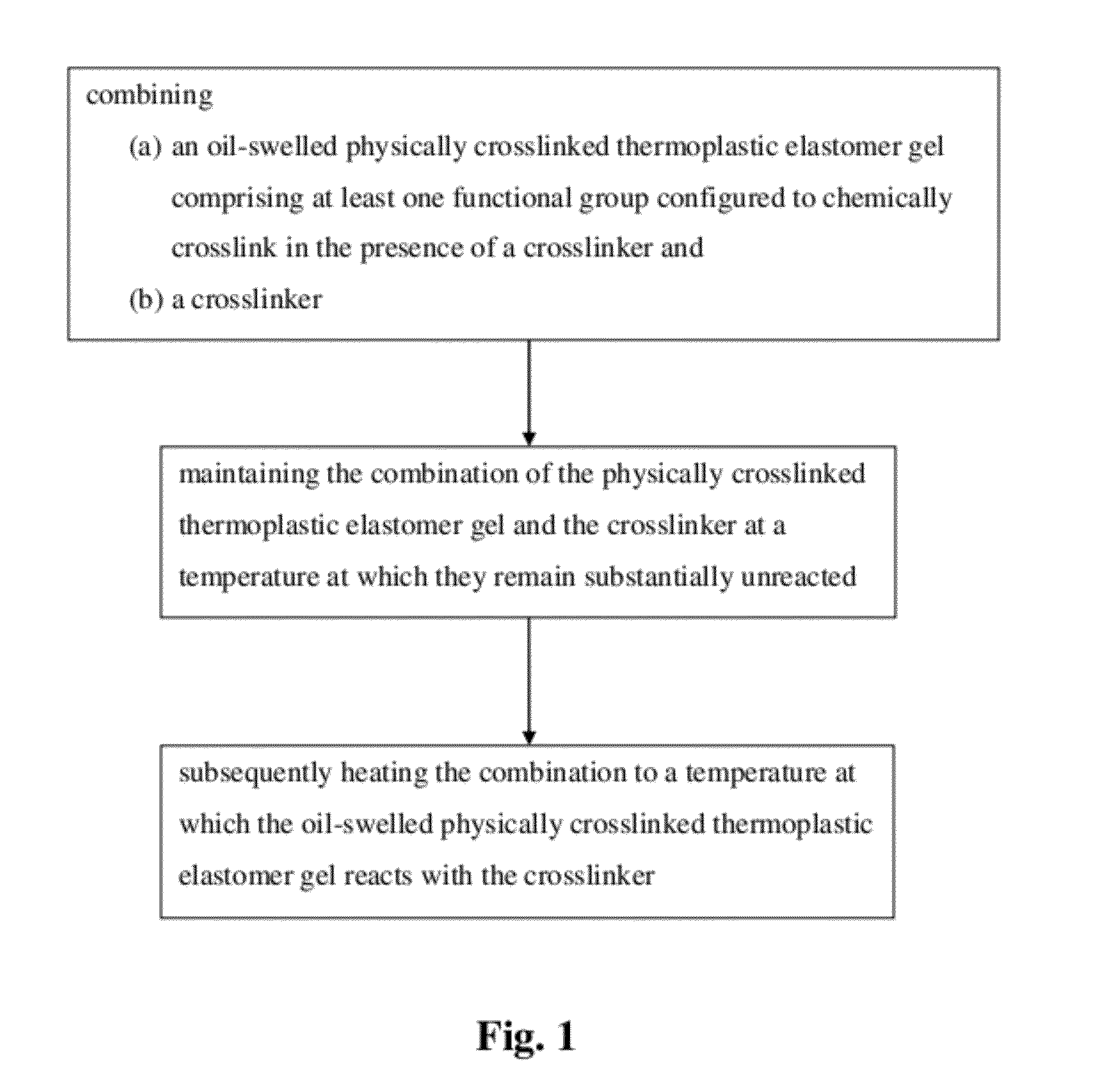

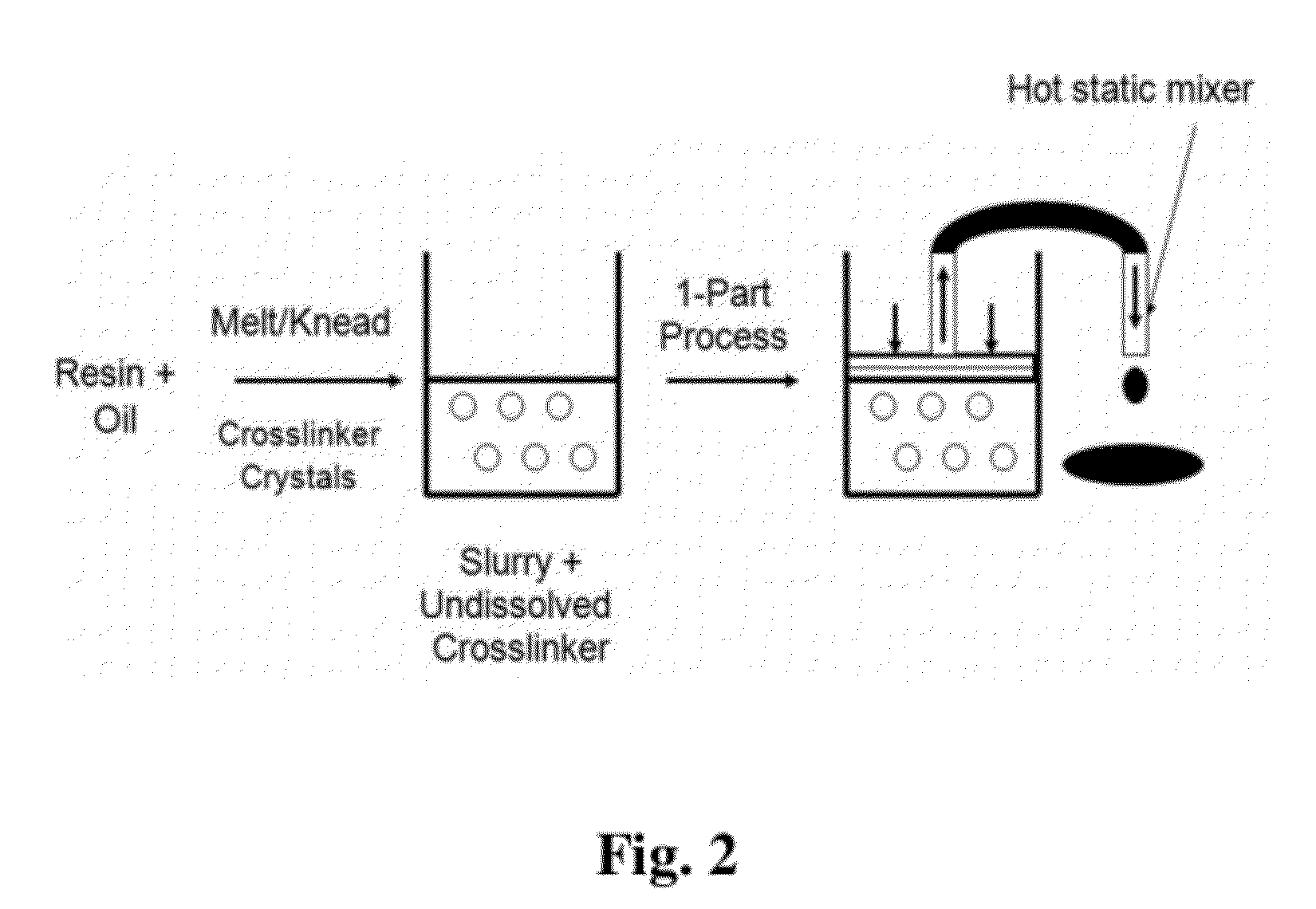

Methods of Processing High Service Temperature Hydrocarbon Gels

InactiveUS20120126455A1Sufficient flame retardancyFoundry mouldsCeramic shaping apparatusThermoplastic elastomerPolymer chemistry

Methods of processing high service temperature crosslinked thermoplastic gels are provided. The methods include combining (a) an oil-swelled physically crosslinked thermoplastic elastomer gel comprising at least one functional group configured to chemically crosslink in the presence of a crosslinker and (b) a crosslinker; maintaining the combination of the physically crosslinked thermoplastic elastomer gel and the crosslinker at a temperature at which they remain substantially unreacted; subsequently heating the combination to a temperature at which the oil-swelled physically crosslinked thermoplastic elastomer gel reacts with the crosslinker.

Owner:COMMSCOPE TECH LLC

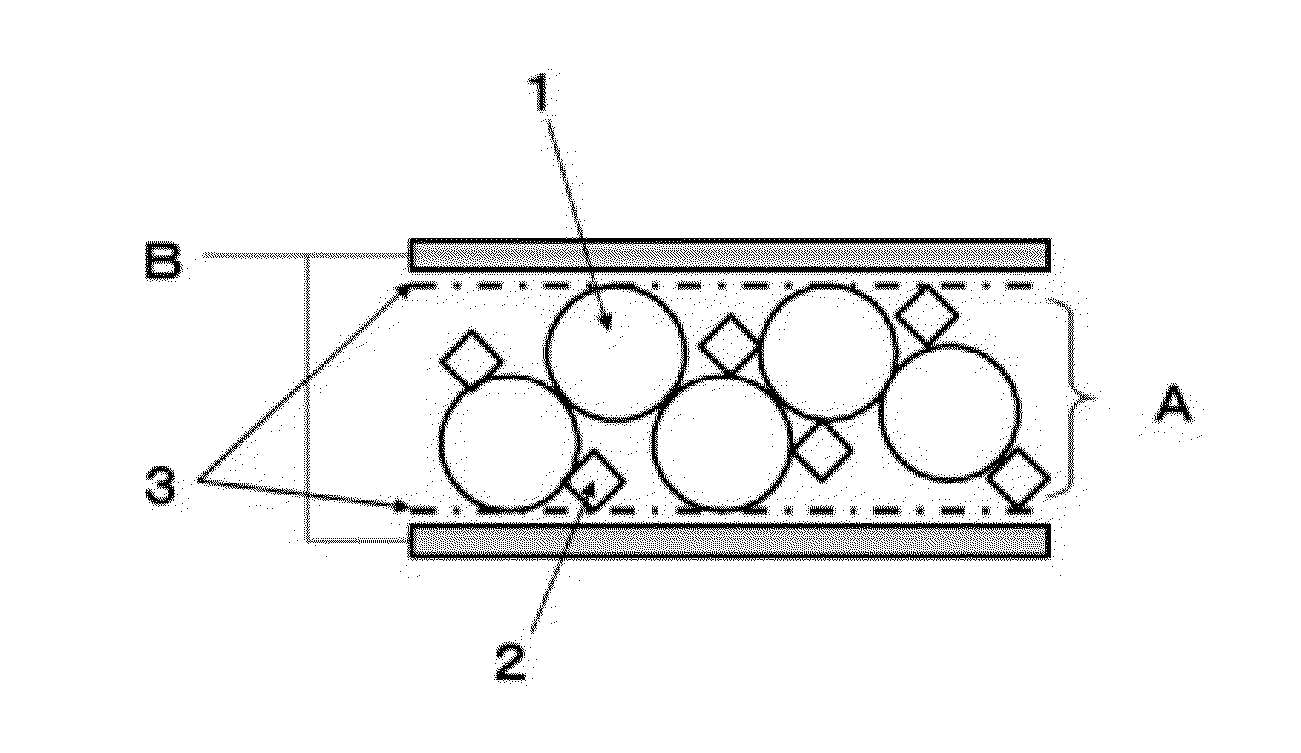

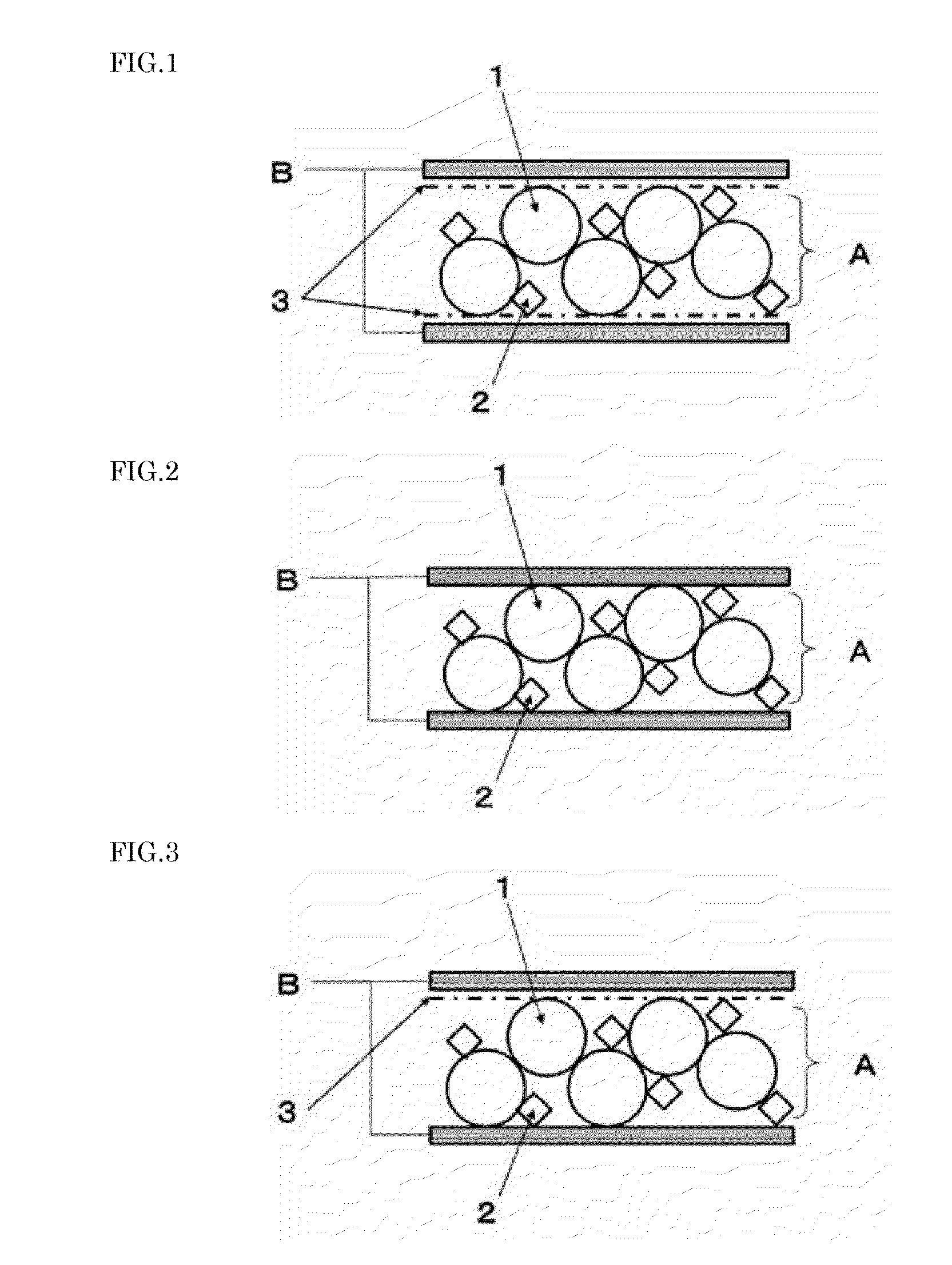

Jacket structure of flame-retardant cable

InactiveCN101609734AAvoid destructionIngenious designRubber insulatorsPlastic/resin/waxes insulatorsEngineeringNeoprene

The invention relates to a jacket structure of a flame-retardant cable, comprising an inner jacket and an outer jacket; wherein, the outer jacket is sleeved on the outer surface of the inner jacket; the jacket structure has the advantages that the outer jacket can be connected with the outer surface of the inner jacket in a sliding manner, the outer jacket and the inner jacket are flame-retardant chlorinated polyethylene rubber jacket, flame-retardant chloroprene rubber jacket or flame-retardant chlorosulfonated polyethylene rubber jacket, and the flame-retardant chlorinated polyethylene rubber jacket adopts the flame-retardant chlorinated polyethylene rubber jacket with a oxygen index more than 35; the jacket structure of the flame-retardant cable has ingenious design and simple structure, effectively prevents that when using cables, too many mechanical damages are generated on cables so that cables are damaged completely, avoids the frequent happening of underground accidents and is applicable to the jacket structure of mine cables.

Owner:上海德力西集团有限公司

Flame retardant composition, flame retardant fiber and fabric formed using the same, and method for their production

InactiveUS20170283989A1Maintain flame retardancyProvide stretch propertyFireproof paintsMonocomponent polyurethanes artificial filamentYarnFire retardant

A flame retardant composition containing a phosphorous containing ammonium salt, a crosslinker, and water is provided, and its application to yarn or fabric to provide a flame retardant yarn or fabric. In a preferred embodiment, the yarn or fabric is made from a polyurethane elastomer, such as a spandex. A method to prepare the flame retardant composition and apply it to the fiber or yarn is also provided.

Owner:SUPREME CORQ

Flame-retardant deodorizing filter

InactiveUS20130139693A1Sufficient flame retardancySufficient adhesivenessGas treatmentIsotope separationActivated carbonPolyvinyl alcohol

[problem] It is provided that an activated carbon sheet to be excellent in removability of hazardous gas component and flame retardancy.[solution] A flame-retardant deodorizing filter comprising an activated carbon layer and a fabric formed on both sides thereof, wherein the fabric has a fiber ratio of one or more kinds selected from cellulose fibers, polyvinyl alcohol fibers, polyacrylonitrile fibers, and phenol fibers in 30% or more; a phosphorus-based flame retardant is contained in an amount of 10 to 70% by weight relative to the fabric weight; an adhesive layer is present between the activated carbon layer and the fabric; the activated carbon particles are firmly adhered by thermoplastic resin binder particles; and the weight per unit area of activated carbon is 50 to 400 g / m2.

Owner:TOYOBO CO LTD

DMC-CF (dimethyl carbonate-carbon fiber) type high-strength composite and application thereof in manhole cover

InactiveCN107418242AHigh specific strengthImprove fatigue resistanceArtificial islandsUnderwater structuresFiberPliability

The invention discloses a DMC-CF (dimethyl carbonate-carbon fiber) type high-strength composite and an application thereof in a manhole cover and relates to the technical field of road facilities. The composite has the properties of being light in weight, high in specific strength, high in seismic performance, good in anti-fatigue performance, resistant to high temperature, acid and alkali and chemical corrosion, good in insulation performance, voltage-resistant, higher in mechanical performance, good in damage safety, high in bearing force, high in precision, low in expansion coefficient, high in weather resistance, sufficient in flame retardance, mildew-proof, water-resistant, oil-resistant, resistant to rust, good in damping and noise reducing performance, sound-proof, bounce-proof, high in anti-theft property, environment-friendly, energy-saving, pollution-free, convenient to mount, good in flexibility, high in strain capacity, good in thermodynamic property, favorable for large-area overall forming and maintenance-free; when the composite is applied to preparation of the manhole cover, the problems occurring in the use process of conventional cast iron well lid or a manhole cover made of a non-metal composite in the prior art are solved.

Owner:XIAMEN JINTING IND TRADE

Adhesive composition and adhesive using same

InactiveUS20100113658A1High strengthSufficient flame retardancyPlastic/resin/waxes insulatorsChloroprene adhesivesPhosphoric Acid EstersPolymer science

To provide an adhesive composition which exhibits sufficient initial strength even in a wet state right after application, and which provides a coating film having sufficient flame retardancy after it is dried, and an adhesive using it.An adhesive composition comprising a chloroprene latex (A), an aromatic phosphate ester type plasticizer (B), and a pH adjusting agent (C).

Owner:DENKA CO LTD

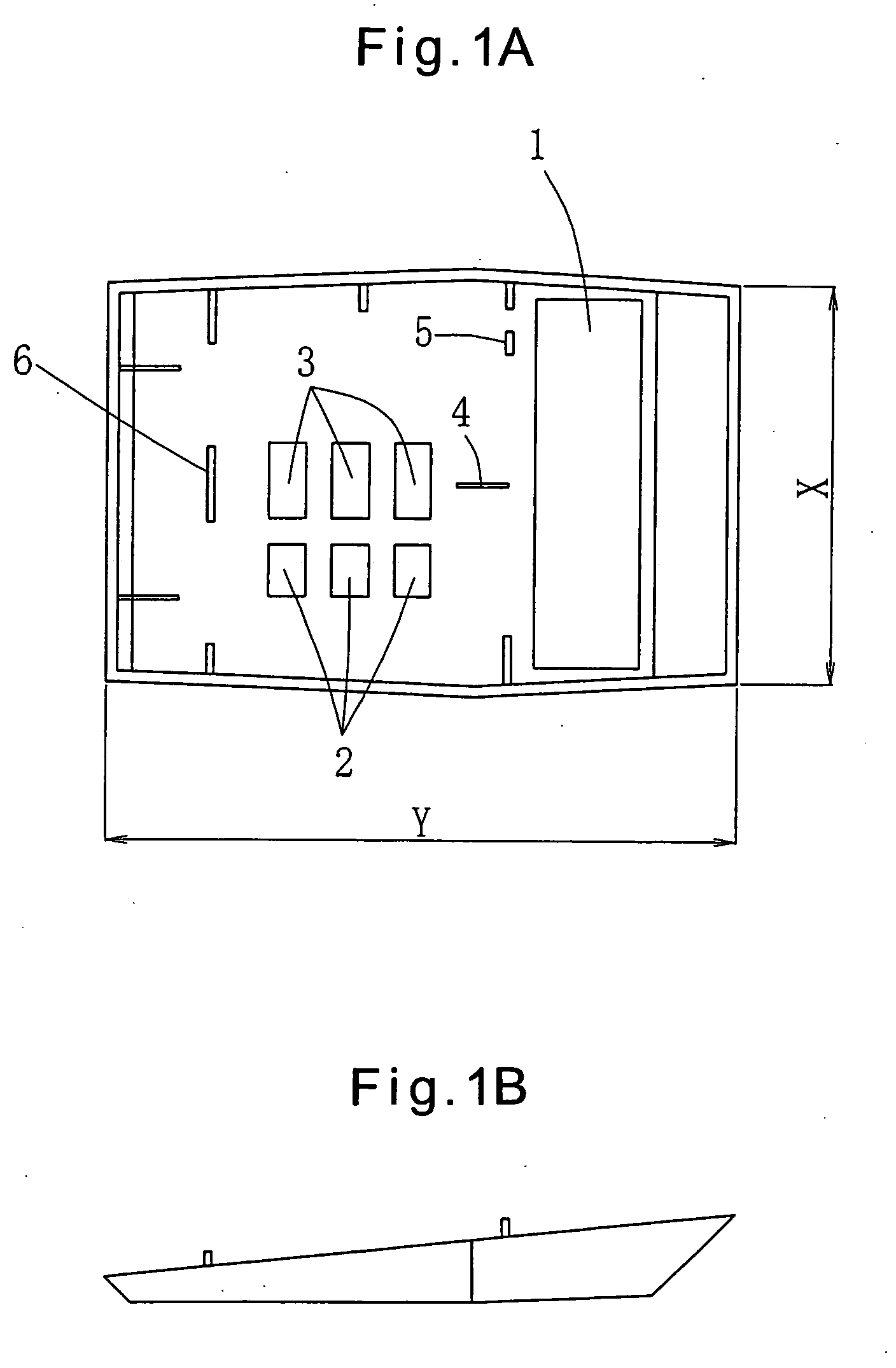

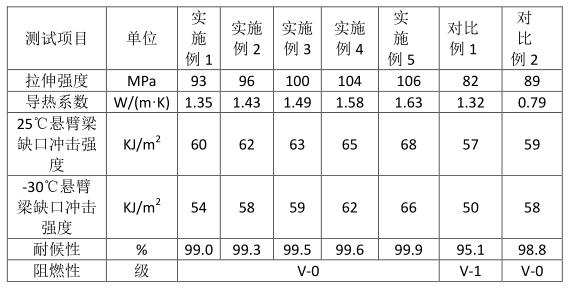

Thermoplastic resin composite material notebook computer C shell and manufacturing process thereof

The invention discloses a thermoplastic resin composite material notebook computer C shell. The C shell is prepared from, by weight, 40 to 50 parts of carbonyl-terminated hyperbranched polycarbonate, 8 to 12 parts of waste aromatic oxadiazole fibers, 30 to 40 parts of PBT resin, 3 to 5 parts of a coupling agent, 3 to 6 parts of dimethyl carbonate oxadiazole benzotriazolyl butyl phenol sulfonate, 5 to 8 parts of graphene fibers, 4 to 6 parts of glass fibers, 1 to 2 parts of an antioxidant, 3 to 5 parts of a compatilizer and 1 to 3 parts of a lubricant. The invention further discloses a manufacturing process of the thermoplastic resin composite material notebook computer C shell. The thermoplastic resin composite material notebook computer C shell disclosed by the invention is excellent in mechanical property, good in heat resistance and heat-conducting property, good in low-temperature impact resistance and sufficient in performance stability.

Owner:安徽英力电子科技股份有限公司

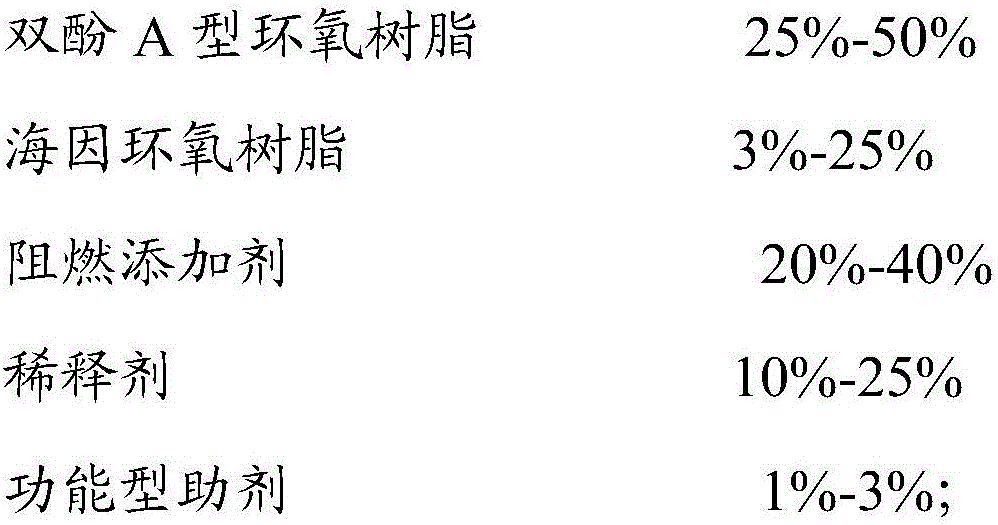

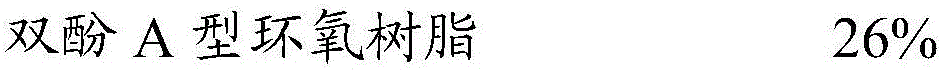

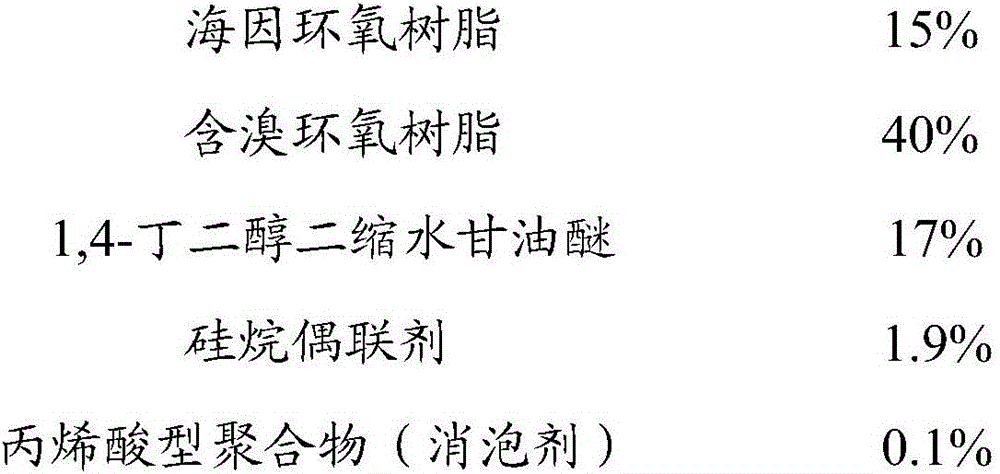

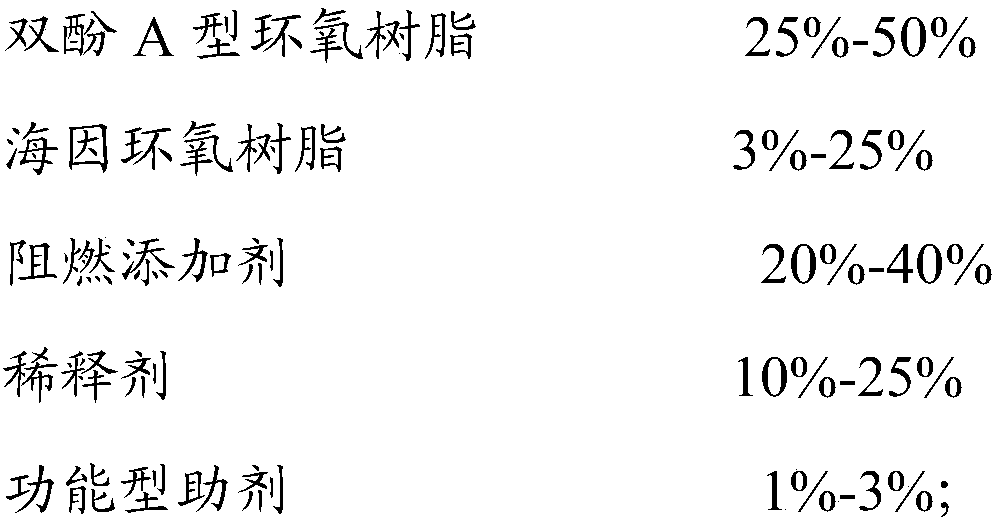

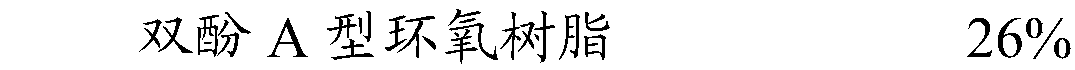

Epoxy resin system for producing telegraph poles and preparation method of epoxy resin system

The invention relates to an epoxy resin system for producing telegraph poles and a preparation method of the epoxy resin system. The epoxy resin system comprises a component A and a component B. The component A comprises 25-50% of bisphenol-A epoxy resin, 3-25% of hydantoin epoxy resin, 20-40% of flame-retardant additives, 10-25% of slow-release agents and 1-3% of functional assistants. The component B comprises 90-97% of curing agents, 1-5% of accelerants and 1-5% of assistants. The epoxy resin system has high heat insulation performance and excellent mechanical property, especially excellent bending performance, has enough flame retardance, and has high wettability to facilitate filament winding; gel reaction can be achieved quickly at the high temperature, and accordingly, production efficiency is improved; the epoxy resin system does not release harmful gases in the production process, thereby being beneficial to environment protection.

Owner:GUANGZHOU POCHELY NEW MATERIAL TECH CO LTD

Elongated article with good flexibility and high flame retardancy

ActiveUS20190194433A1Good dimensional stabilityCost and time-consumingPlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneElastomer

The invention relates to elongated articles and polymer compositions used for preparing the elongated articles. The elongated articles comprise an inner structure / one or more elements including a static / moving current medium or communication medium; and a halogen-free polymer composition surrounding the element(s). The polymer composition includes a linear very low density polyethylene (VLDPE) composition and one or more polyolefin-elastomers. In addition, the polymer composition includes a flame retardant filler.

Owner:LEONI KABEL GMBH

Epoxy resin system for preparing utility poles and its preparation method

The invention relates to an epoxy resin system for producing telegraph poles and a preparation method of the epoxy resin system. The epoxy resin system comprises a component A and a component B. The component A comprises 25-50% of bisphenol-A epoxy resin, 3-25% of hydantoin epoxy resin, 20-40% of flame-retardant additives, 10-25% of slow-release agents and 1-3% of functional assistants. The component B comprises 90-97% of curing agents, 1-5% of accelerants and 1-5% of assistants. The epoxy resin system has high heat insulation performance and excellent mechanical property, especially excellent bending performance, has enough flame retardance, and has high wettability to facilitate filament winding; gel reaction can be achieved quickly at the high temperature, and accordingly, production efficiency is improved; the epoxy resin system does not release harmful gases in the production process, thereby being beneficial to environment protection.

Owner:GUANGZHOU POCHELY NEW MATERIAL TECH CO LTD

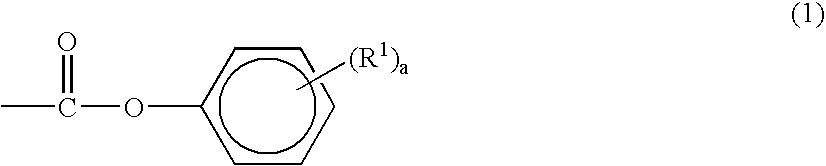

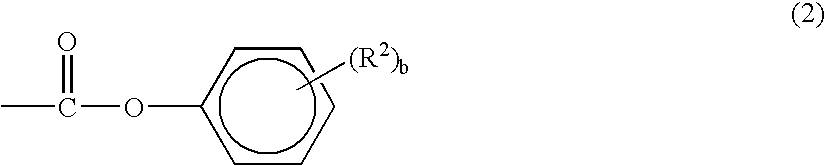

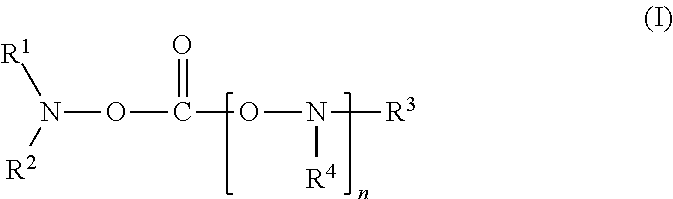

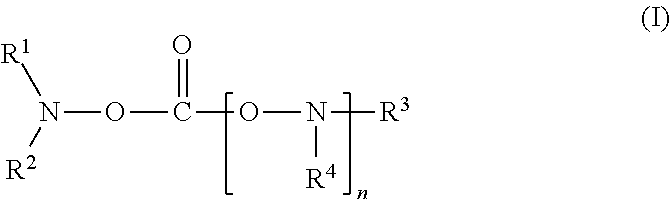

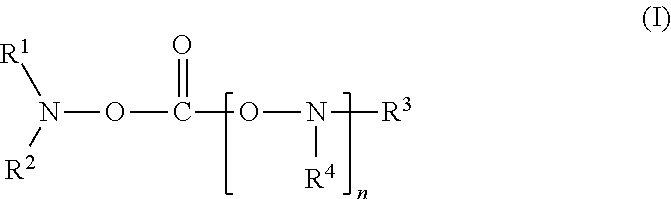

Flame retardant for thermosetting resin including aromatic phosphoric acid ester, thermosetting resin composition including same, and cured material and application of same

PendingUS20210309917A1Sufficient flame retardancyReduce heat resistance requirementsPrinted circuit aspectsSynthetic resin layered productsPhosphoric Acid EstersPolymer science

A flame retardant for thermosetting resin containing an aromatic phosphoric acid ester represented by the general formula (I):wherein R1 to R4 each independently represent a hydrogen atom, a C1-4 alkyl group, or a C1-4 alkoxy group; R5, R6, and R9 each independently represent a C1-10 alkyl group or a C1-10alkoxy group; R7 and R8 each independently represent a C1-4 alkyl group or a C1-4 alkoxy group; n represents an integer of 1 to 10; n1 and n2 each independently represent an integer of 0 to 3; m1 and m2 each independently represent an integer of 0 to 4; p represents an integer of 0 to 26; and k represents an integer of 1 to 12; and when p is 2 or more, any two substituents R9 may be bonded to each other, and may be bonded to a carbon atom(s) of a ring to which the above substituents R9 are bonded, forming another ring.

Owner:DIAHACHI CHEMICAL INDUSTRY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com